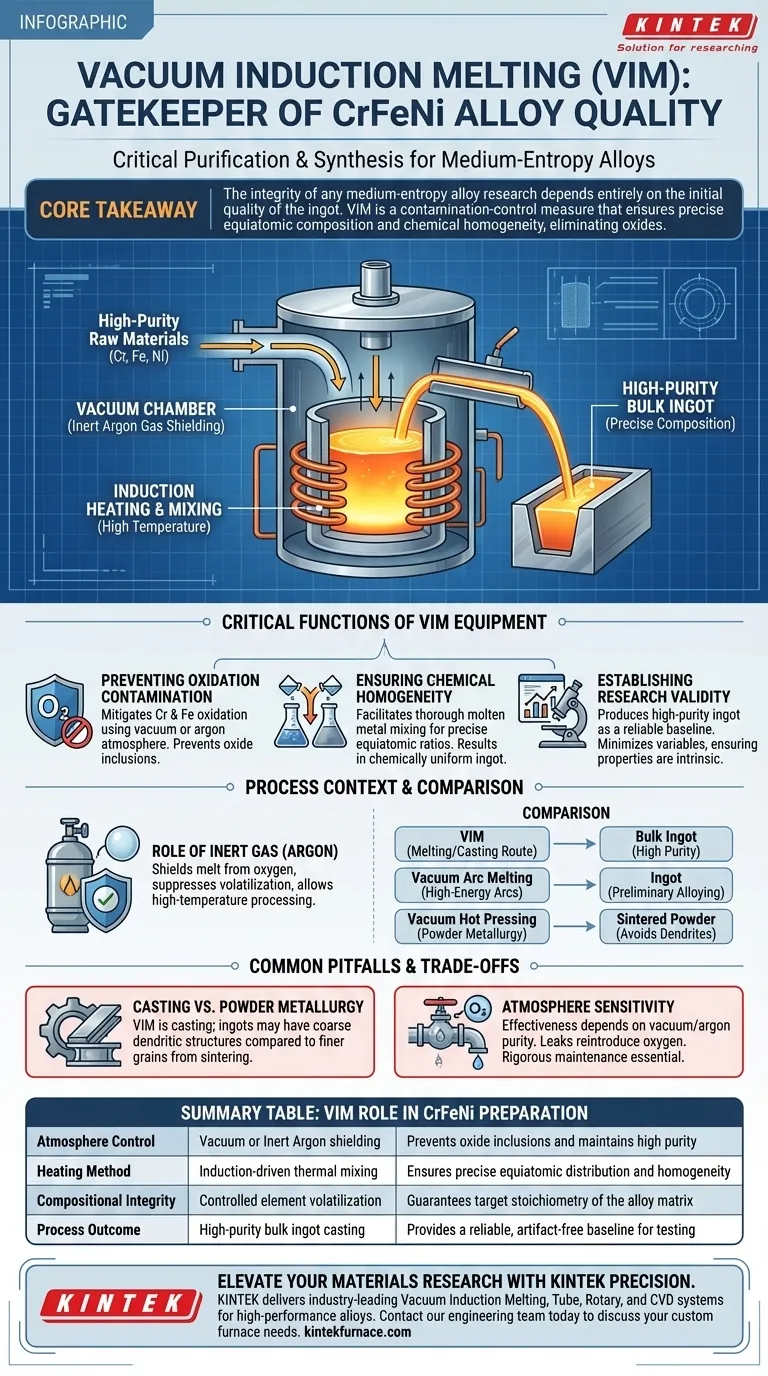

Vacuum induction melting (VIM) serves as the critical purification and synthesis stage in the production of CrFeNi medium-entropy alloys. By utilizing a high-temperature environment shielded by inert argon gas, this equipment facilitates the thorough melting of high-purity raw materials while strictly preventing oxidation and impurity introduction.

Core Takeaway The integrity of any medium-entropy alloy research depends entirely on the initial quality of the ingot. Vacuum induction melting is not merely a heating process; it is a contamination-control measure that ensures the CrFeNi alloy achieves a precise equiatomic composition and chemical homogeneity, eliminating oxides that would otherwise compromise subsequent testing.

The Critical Functions of VIM Equipment

Preventing Oxidation Contamination

The primary role of VIM equipment is environmental control.

Elements within the CrFeNi system, particularly Chromium (Cr) and Iron (Fe), are susceptible to oxidation at high temperatures.

The VIM furnace mitigates this by maintaining a vacuum or an inert argon atmosphere. This prevents the formation of oxide inclusions that would degrade the material's purity.

Ensuring Chemical Homogeneity

Achieving a true "medium-entropy" state requires precise atomic ratios.

VIM equipment facilitates the thorough mixing of the molten metal.

This results in a chemically uniform ingot, ensuring that the elements are evenly distributed throughout the matrix rather than segregated in pockets.

Establishing Research Validity

The output of the VIM process acts as the baseline for all subsequent materials research.

By producing a high-purity ingot with a precise equiatomic composition, the equipment minimizes variables.

This ensures that any mechanical or physical properties observed later are intrinsic to the alloy design, not artifacts of impurities introduced during melting.

Understanding the Process Context

The Role of Inert Gas

While "vacuum" is in the name, the introduction of inert gas is a key operational step.

Argon gas protection is used during the melting phase to suppress volatilization of specific elements while shielding the melt from oxygen.

This balance allows for high-temperature processing without altering the target stoichiometry of the CrFeNi alloy.

Comparison to Other Techniques

It is helpful to distinguish VIM from other synthesis methods to understand its specific utility.

While Vacuum Arc Melting also produces ingots using high-energy arcs for preliminary alloying, VIM relies on induction heating for mixing.

Conversely, Vacuum Hot Pressing is a powder metallurgy route used to sinter powders to avoid casting defects like dendrites; VIM is specifically a melting/casting route to create bulk ingots.

Common Pitfalls and Trade-offs

Casting Microstructure vs. Powder Metallurgy

While VIM is excellent for chemical uniformity, it is fundamentally a casting process.

Users should be aware that cast ingots may still exhibit coarse dendritic structures compared to the finer grains achieved through powder metallurgy (sintering).

However, for creating the initial alloy stock from raw elements, VIM remains the standard for purity.

Atmosphere Sensitivity

The effectiveness of VIM is entirely dependent on the quality of the vacuum and the purity of the argon gas.

Even minor leaks or low-grade gas can reintroduce the oxygen that the equipment is designed to exclude.

Rigorous maintenance of the vacuum seals and gas lines is non-negotiable for CrFeNi preparation.

Making the Right Choice for Your Goal

- If your primary focus is creating a pristine baseline ingot: VIM is the mandatory choice to ensure high purity and precise chemical composition for CrFeNi alloys.

- If your primary focus is avoiding dendritic segregation: Consider post-processing the VIM ingot or exploring powder metallurgy routes (like Vacuum Hot Pressing) depending on the desired final microstructure.

Ultimately, the Vacuum Induction Melting furnace is the gatekeeper of quality, transforming raw elements into a scientifically valid CrFeNi alloy suitable for rigorous characterization.

Summary Table:

| Feature | VIM Role in CrFeNi Preparation | Benefit to Research |

|---|---|---|

| Atmosphere Control | Vacuum or Inert Argon shielding | Prevents oxide inclusions and maintains high purity |

| Heating Method | Induction-driven thermal mixing | Ensures precise equiatomic distribution and homogeneity |

| Compositional Integrity | Controlled element volatilization | Guarantees target stoichiometry of the alloy matrix |

| Process Outcome | High-purity bulk ingot casting | Provides a reliable, artifact-free baseline for testing |

Elevate Your Materials Research with KINTEK Precision

High-performance CrFeNi alloys demand the absolute purity that only expert-engineered systems can provide. KINTEK delivers industry-leading Vacuum Induction Melting, Tube, Rotary, and CVD systems, all designed to eliminate contamination and ensure chemical homogeneity. Whether you are developing medium-entropy alloys or advanced ceramics, our equipment is fully customizable to meet your specific laboratory requirements.

Ready to achieve superior chemical uniformity? Contact our engineering team today to discuss your custom furnace needs.

Visual Guide

References

- Anna M. Manzoni, Christiane Stephan‐Scherb. High‐Temperature Oxidation of the CrFeNi Medium‐Entropy Alloy. DOI: 10.1002/adem.202500400

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What safety advantages do induction gold melting furnaces offer? Flameless, Contained Melting for Maximum Operator Safety

- What future advancements are expected in IGBT technology for induction melting? Higher Power Density & Intelligent Control

- What is the purpose of an induction furnace? Achieve Superior Metal Melting with Precision & Purity

- What industries commonly use vacuum or protective atmosphere induction furnaces? Essential for Aerospace, Medical, and More

- What are the benefits of vacuum induction smelting technology? Achieve Superior Purity and Performance for Advanced Materials

- What future applications might benefit from induction technology? Unlock Next-Gen Manufacturing & Green Energy

- What are the advantages of an IGBT induction melting furnace? Boost Efficiency & Productivity

- What core experimental environments does a vacuum induction furnace provide for simulating rare earth element modification in bearing steel?