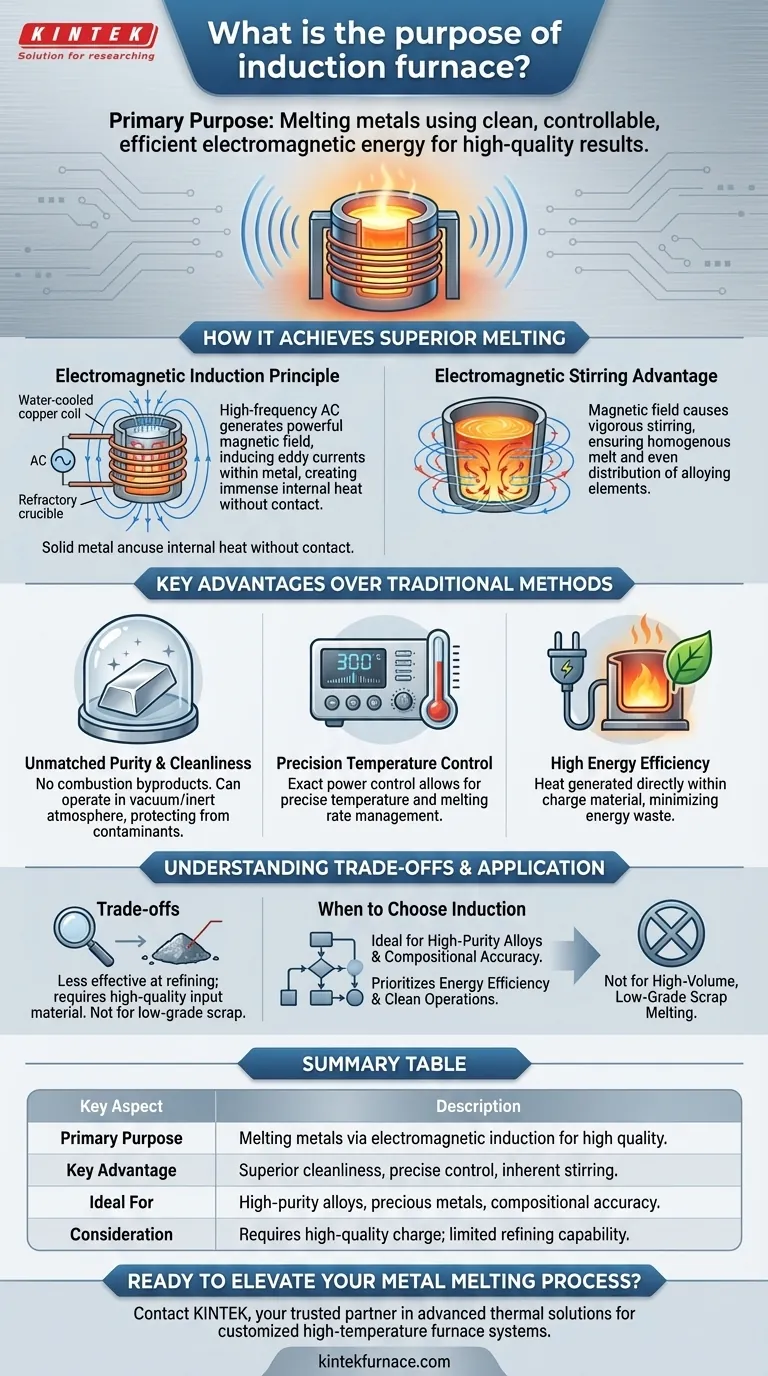

In short, the primary purpose of an induction furnace is to melt metals using clean, controllable, and efficient electromagnetic energy. Instead of burning fuel, it generates heat directly within the metal itself, allowing for the production of high-quality iron, steel, copper, aluminum, and precious metal alloys.

The core reason to choose an induction furnace is not just to melt metal, but to achieve a superior level of control over the process. Its design delivers unmatched cleanliness and precision, making it the definitive choice for applications where the final quality and composition of the metal are critical.

How an Induction Furnace Achieves Superior Melting

To understand the purpose of an induction furnace, you must first understand its unique operating principle. Unlike traditional furnaces that rely on external heat sources, an induction furnace is a fundamentally different and more direct method.

The Principle of Electromagnetic Induction

An induction furnace uses a powerful, high-frequency alternating current passed through a large copper coil. This coil, which is cooled by water, surrounds a non-conductive container (a refractory crucible) holding the metal to be melted.

The alternating current in the coil generates a powerful and rapidly changing magnetic field. This magnetic field penetrates the metal inside the crucible, inducing strong electrical currents within it, known as eddy currents.

The metal's natural electrical resistance fights against these currents, generating immense heat directly inside the material. This is the same principle as a standard electrical heater, but it happens without any physical contact and from the inside out.

The Advantage of Electromagnetic Stirring

A secondary effect of the intense magnetic field is a vigorous stirring action within the molten metal. This electromagnetic stirring ensures the melt is homogenous.

This is critical when creating alloys, as it guarantees that elements like chromium, nickel, or manganese are evenly distributed throughout the batch, resulting in a consistent, high-quality final product.

Key Advantages Over Traditional Methods

The choice to use an induction furnace is driven by several key advantages over fuel-fired (cupola) or electric arc furnaces. These benefits directly address the needs of modern, high-precision metal processing.

Unmatched Purity and Cleanliness

Because no fuel is burned, there are no combustion byproducts like sulfur or carbon to contaminate the metal. This makes induction melting an exceptionally clean process.

Furthermore, the process can be contained within a vacuum or an inert atmosphere, protecting the melt from oxygen and nitrogen in the air. This is essential for producing reactive metals or ultra-high-purity alloys.

Precision Temperature Control

The power supplied to the induction coil can be controlled with extreme precision. This gives the operator fine-grained control over the temperature and melting rate.

This level of control is vital for producing complex alloys that have narrow melting ranges and specific temperature requirements for adding alloying elements.

High Energy Efficiency

Heat is generated directly within the charge material, which is far more efficient than trying to transfer heat from an external flame or electric arc. Less energy is wasted heating the furnace walls or escaping into the environment.

Understanding the Trade-offs

While powerful, the induction furnace is not the universal solution for all melting operations. Understanding its limitations is key to making an informed decision.

Less Effective at Refining

Induction furnaces are primarily for melting, not refining. The inherent stirring action works against the separation of slag, which is a key part of removing impurities in other furnace types like an Electric Arc Furnace (EAF).

Therefore, induction furnaces require a higher-quality, cleaner input material, as they have limited capability to refine low-grade scrap.

Sensitivity to Charge Material

The efficiency of the induction process depends on the electrical properties of the material being melted. The furnace works best with a well-packed charge of solid metal.

Using very fine particles or loose, low-density scrap can hinder performance and efficiency, requiring more careful selection and preparation of raw materials.

When to Choose an Induction Furnace

Your decision should be guided by the specific quality requirements and operational goals of your foundry or metalworking facility.

- If your primary focus is high-purity alloys and compositional accuracy: The unparalleled cleanliness and precision control of an induction furnace make it the ideal choice.

- If your primary focus is high-volume melting of lower-grade scrap: A more robust method like an electric arc furnace, which is better at handling slag and impurities, is likely more suitable.

- If your primary focus is energy efficiency and environmental standards: The induction furnace's high efficiency and lack of direct emissions offer a significant operational advantage.

Ultimately, selecting an induction furnace is a strategic decision for operations where metal quality, control, and efficiency are the paramount goals.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Purpose | Melting metals using electromagnetic induction for high-quality results. |

| Key Advantage | Superior cleanliness, precise temperature control, and inherent stirring. |

| Ideal For | High-purity alloys, precious metals, and applications requiring compositional accuracy. |

| Consideration | Requires high-quality charge material; less effective for refining impurities. |

Ready to Elevate Your Metal Melting Process?

Does your operation demand the superior purity, precision control, and energy efficiency of an induction furnace? KINTEK is your trusted partner in advanced thermal solutions.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories and foundries with robust high-temperature furnace systems. Our expertise extends to customizing solutions to meet your unique melting requirements precisely.

Let's discuss how our technology can enhance your metal quality and operational efficiency.

Contact our experts today for a personalized consultation!

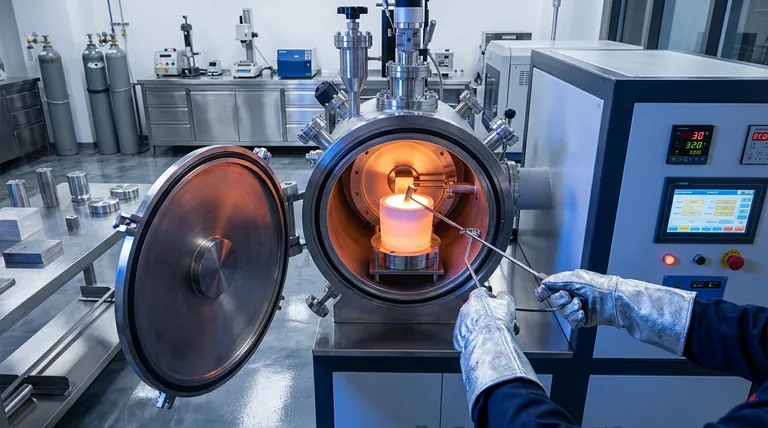

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What frequency ranges are used in induction heating for different applications? Optimize Your Process with the Right Frequency

- How does a vacuum induction melting furnace operate? Achieve Superior Metal Purity and Performance

- Why is a Vacuum Induction Melting furnace (VIM) used for Cu-Zn-Al-Sn alloys? Achieve Precision Composition Control

- Why is it necessary to reduce the applied secondary voltage during the arc furnace process? Protect Your Furnace and Boost Efficiency

- What are the advantages of induction melting? Achieve Faster, Cleaner, and More Efficient Metal Processing

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What is the role of a Vacuum Induction Melting Furnace in chromium-steel prep? Secure Purity & Composition Control

- What advantages does vacuum induction melting offer? Achieve Unmatched Metal Purity and Performance