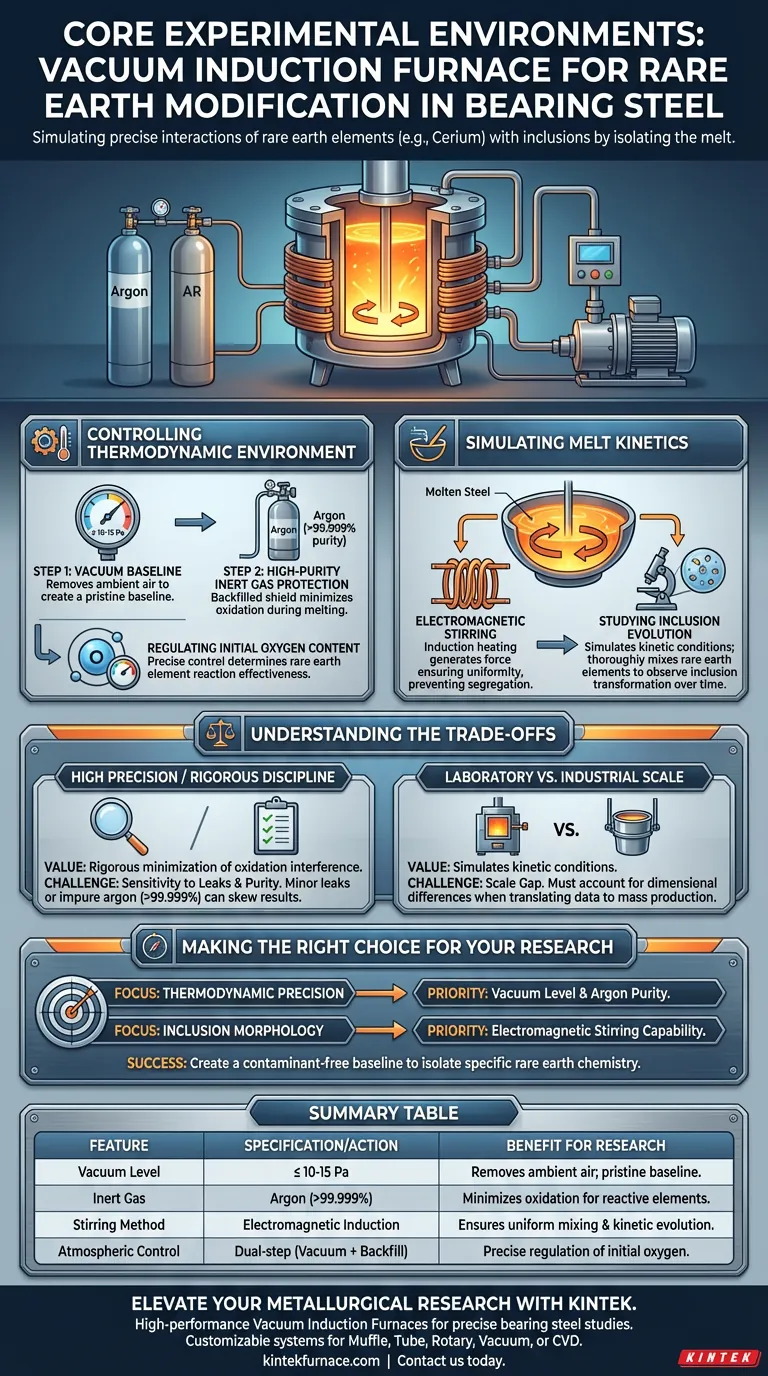

A vacuum induction furnace establishes a strictly controlled experimental environment defined by a deep vacuum, high-purity inert gas protection, and electromagnetic stirring. These conditions are critical for isolating the melt from atmospheric interference, allowing for the precise simulation of how rare earth elements (like Cerium) interact with and modify inclusions in bearing steel.

The primary value of this environment is the rigorous minimization of oxidation interference. By controlling the atmosphere and utilizing induced stirring, researchers can isolate the specific chemical effects of rare earth elements without the variables introduced by ambient air.

Controlling the Thermodynamic Environment

To accurately study rare earth modification, you must first eliminate uncontrolled variables. The vacuum induction furnace achieves this through a two-step atmospheric control process.

The Vacuum Baseline

The furnace is capable of achieving a vacuum level of 10 Pa (or generally below 15 Pa). This creates a pristine baseline by removing ambient air from the chamber before heating begins.

High-Purity Inert Gas Protection

Once the vacuum is established, the chamber is backfilled with high-purity argon gas (purity >99.999%). This provides a protective shield that minimizes oxidation interference during the melting process, which is crucial when working with highly reactive rare earth elements.

Regulating Initial Oxygen Content

The combination of vacuum and argon allows for the precise control of the initial oxygen content in the steel. This is the fundamental variable needed to determine how effectively rare earth elements will react with oxygen to modify inclusions.

Simulating Melt Kinetics

Beyond atmospheric control, the furnace provides specific physical conditions that mimic industrial steelmaking dynamics.

Electromagnetic Stirring

The induction heating mechanism inherently generates an electromagnetic stirring effect within the molten steel. This force ensures the uniformity of the liquid steel components, preventing the segregation of heavier or lighter elements.

Studying Inclusion Evolution

This stirring simulates the kinetic conditions necessary for studying inclusion evolution. It ensures that the rare earth elements mix thoroughly, allowing researchers to observe how inclusions transform physically and chemically over time.

Understanding the Trade-offs

While a vacuum induction furnace provides high precision, it requires rigorous operational discipline to ensure data validity.

Sensitivity to Leaks and Purity

The "controllability" of the environment relies entirely on the integrity of the seal and the gas source. Even a minor vacuum leak or a slight drop in argon purity below 99.999% can introduce enough oxygen to skew the results of a rare earth study.

The Scale Gap

While electromagnetic stirring simulates kinetic conditions, the scale of a laboratory furnace differs from industrial ladles. Researchers must account for these dimensional differences when translating inclusion evolution data to mass production scenarios.

Making the Right Choice for Your Research

When utilizing a vacuum induction furnace for bearing steel research, tailor your approach to your specific data requirements.

- If your primary focus is thermodynamic precision: Prioritize the vacuum level (10 Pa) and argon purity to strictly control initial oxygen content.

- If your primary focus is inclusion morphology: Rely on the electromagnetic stirring capability to ensure the rare earth elements are distributed uniformly throughout the melt.

The success of your simulation depends on using the furnace not just to melt steel, but to create a contaminant-free baseline that isolates the specific chemistry of the rare earth elements.

Summary Table:

| Feature | Specification/Action | Benefit for Research |

|---|---|---|

| Vacuum Level | ≤ 10-15 Pa | Removes ambient air to create a pristine baseline. |

| Inert Gas | Argon (>99.999% purity) | Minimizes oxidation interference for reactive elements. |

| Stirring Method | Electromagnetic Induction | Ensures uniform mixing and simulates kinetic evolution. |

| Atmospheric Control | Dual-step (Vacuum + Backfill) | Allows precise regulation of initial oxygen content. |

Elevate Your Metallurgical Research with KINTEK

Precision in rare earth modification studies requires an environment free from contaminants. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Induction Furnaces designed to meet the rigorous demands of bearing steel research. Our systems provide the deep vacuum and high-purity gas control necessary to isolate chemical variables and achieve repeatable results.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, all our lab high-temp furnaces are fully customizable to your unique experimental needs. Contact us today to discuss your project requirements and see how our advanced heating solutions can drive your innovation forward.

Visual Guide

References

- Ning Wang, Haichuan Wang. The Modification of Aluminum Oxide Inclusions in Bearing Steel under Different Cleanliness Conditions by Rare Earth Elements. DOI: 10.3390/met14080861

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a vacuum induction furnace play in Fe-Mn-Si alloy melting? Ensuring Purity and Shape Memory Precision

- What is an IGBT induction melting machine? Unlock Faster, More Efficient Metal Melting

- What is a vacuum induction furnace and how does it differ from other vacuum sintering furnaces? Discover the Key Differences

- What is the role of a Vacuum Induction Melting (VIM) furnace in Invar 36 production? Ensure Purity & Precision

- What are the advantages of vacuum casting? Ideal for High-Fidelity Prototypes and Low-Volume Production

- What role does a non-consumable vacuum arc furnace play in Ti–Cu alloy preparation? Achieving High-Purity Synthesis

- How does an induction furnace improve energy efficiency in gold melting? Achieve Faster, Purer Melts

- What maintenance practices are recommended for induction-heated vacuum furnaces? Ensure Longevity and Reliability