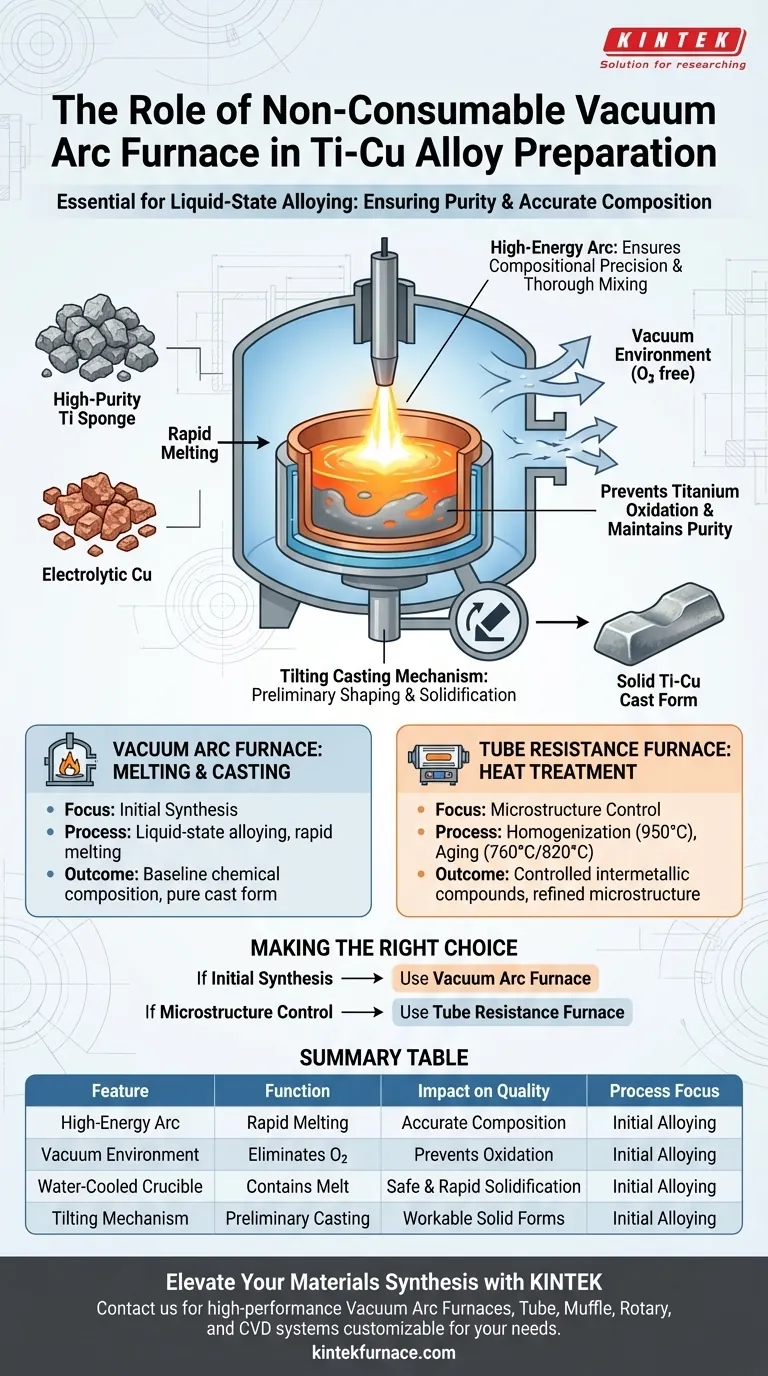

The non-consumable vacuum arc furnace serves as the foundational tool for the initial synthesis and melting of Titanium-Copper (Ti–Cu) alloys. Its primary function is to generate a high-energy arc that rapidly melts raw materials—specifically high-purity titanium sponge and electrolytic copper—while strictly controlling the chemical atmosphere.

Core Takeaway The non-consumable vacuum arc furnace is essential for the liquid-state alloying phase, utilizing a vacuum environment to prevent titanium oxidation while employing a water-cooled crucible to facilitate rapid melting and preliminary casting.

Achieving Accurate Chemical Composition

The Role of the High-Energy Arc

The furnace employs a high-energy arc as its heat source. This intense thermal input allows for the rapid melting of materials with high melting points, specifically high-purity titanium sponge and electrolytic copper.

Ensuring Compositional Precision

Because titanium is highly reactive, maintaining the exact ratio of elements is difficult in open air. The rapid melting process provided by the arc ensures the raw materials mix thoroughly before solidifying, establishing the baseline accuracy of the alloy's chemical composition.

Environmental Protection and Purity

The Necessity of Vacuum Conditions

Titanium alloys are extremely sensitive to oxygen at high temperatures. The furnace operates under a vacuum environment (often backfilled with inert gases) to shield the molten metal.

Preventing Oxidation

This protective environment is critical for preventing the oxidation of titanium. By eliminating oxygen exposure during the melt, the furnace ensures the material retains its intended purity and mechanical potential.

Hardware and Preliminary Shaping

Water-Cooled Copper Crucible

The melting process takes place within a water-cooled copper crucible. This component contains the melt and manages the extreme heat, facilitating the initial consolidation of the liquid metal.

Tilting Casting Mechanism

Beyond simple melting, this furnace is equipped for preliminary shaping. A tilting casting mechanism allows the operator to pour the molten alloy, transitioning it from a liquid mixture into a solid cast form ready for further processing.

Understanding the Process Distinctions

It is vital to distinguish the role of the vacuum arc furnace from downstream heat treatment equipment.

Melting vs. Heat Treatment

The vacuum arc furnace is strictly for melting and casting. It does not provide the precise, long-duration temperature control required for solid-state phase transformations.

Downstream Homogenization

For processes like homogenization (at 950°C) or aging (at 760°C/820°C), a tube resistance furnace is required. While the arc furnace creates the alloy, the tube furnace is responsible for controlling the precipitation of intermetallic compounds (like Ti2Cu) through precise thermal regulation.

Making the Right Choice for Your Goal

To ensure the successful preparation of Ti-Cu alloys, select the equipment that matches your processing stage:

- If your primary focus is initial synthesis: Use the non-consumable vacuum arc furnace to melt titanium sponge and copper without oxidation.

- If your primary focus is microstructure control: Move the cast alloy to a tube resistance furnace to regulate precipitate size and distribution through aging treatments.

The vacuum arc furnace is the gatekeeper of purity, ensuring the alloy is chemically correct before any microstructural tuning begins.

Summary Table:

| Feature | Function in Ti-Cu Preparation | Impact on Quality |

|---|---|---|

| High-Energy Arc | Rapid melting of Ti sponge and electrolytic Cu | Ensures accurate chemical composition |

| Vacuum Environment | Eliminates oxygen exposure during melting | Prevents titanium oxidation and maintains purity |

| Water-Cooled Crucible | Contains and cools the molten metal | Facilitates safe melting and rapid solidification |

| Tilting Mechanism | Preliminary casting and shaping | Transforms liquid alloy into workable solid cast forms |

| Process Focus | Initial liquid-state alloying | Establishes the baseline material for heat treatment |

Elevate Your Materials Synthesis with KINTEK

Precise alloy preparation begins with the right thermal technology. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Arc Furnaces, Tube, Muffle, Rotary, and CVD systems, all customizable for your unique laboratory needs. Whether you are performing initial synthesis of Ti-Cu alloys or precise downstream aging treatments, our equipment ensures maximum purity and control.

Ready to optimize your lab's high-temperature processes? Contact us today to discuss your project and discover how our specialized furnace solutions can drive your research forward.

Visual Guide

References

- Daisy Rabbitt. Antimicrobial Titanium–Copper Alloys: The Role of Microstructure in Arc‐Melted Compositions. DOI: 10.1002/adem.202500347

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the key components of a modern induction melting furnace? A Guide to Core Systems & Performance

- What is the function of a non-consumable vacuum arc melting furnace? Synthesizing Ultra-Pure Zr2Fe-based Alloys

- Why is preheating the mold to 300°C necessary for AZ91D casting? Optimize Structural Integrity and Grain Refinement

- What is a resonant tank circuit and how is it used in the described induction heater? Boost Efficiency with Energy Oscillation

- What are the key components of a vacuum casting furnace? Essential Parts for High-Purity Metal Casting

- What is the primary objective of using a VIM furnace in magnet production? Ensure Purity and Homogeneity

- What is the function of a high-temperature vacuum induction furnace in (Hf─Zr─Ti)C synthesis? Achieve 2100°C Precision

- What makes induction vacuum melting possible? Unlock Ultra-Pure Metal Production