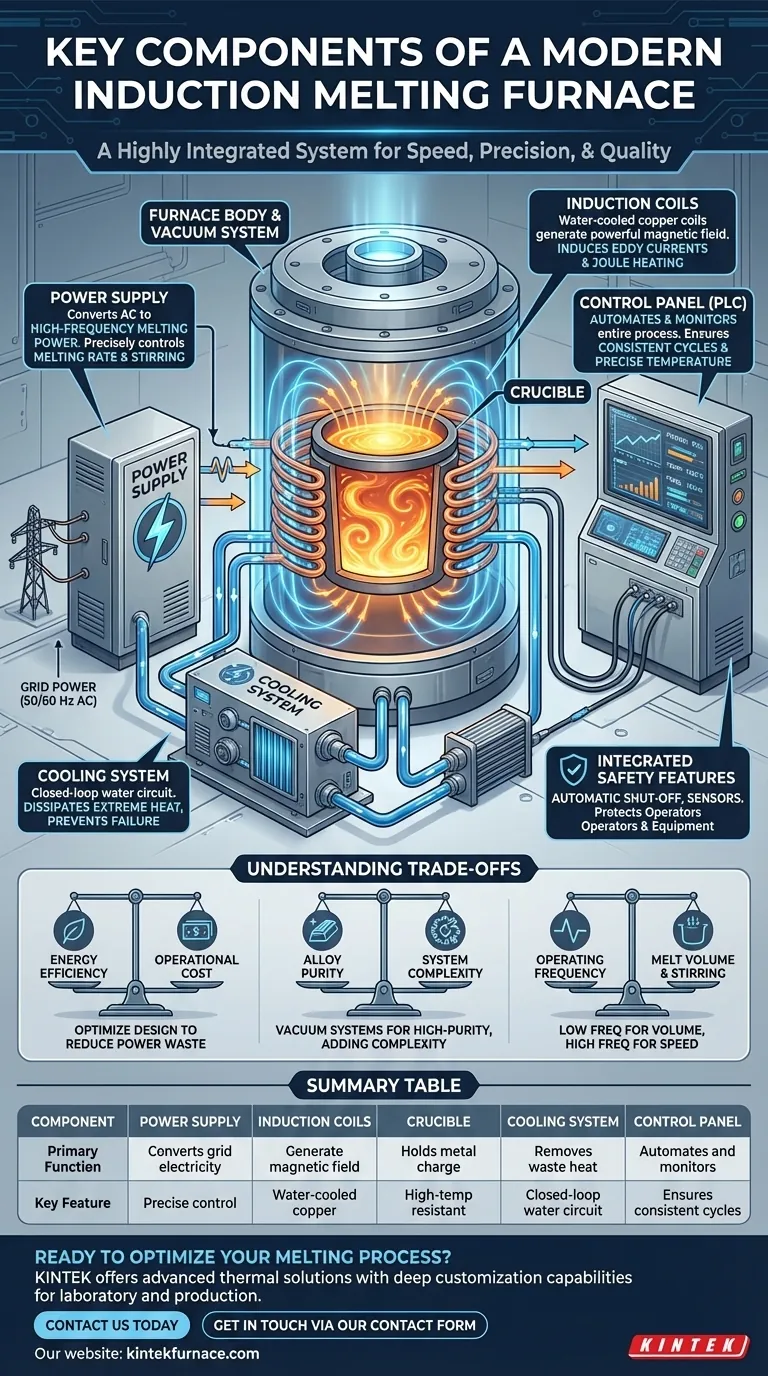

At its core, a modern induction furnace is a highly integrated system with five key components: a power supply to convert electricity, water-cooled induction coils to create a magnetic field, a crucible to hold the metal, a cooling system to manage extreme heat, and a control panel to automate and regulate the entire process. These elements work in concert to melt conductive metals with remarkable speed and precision, using no direct flame or contact.

An induction furnace is not merely a heater; it is a sophisticated system designed for precise energy control. Understanding how its components interact is the key to leveraging its full potential for efficiency, material quality, and operational safety.

The Heart of the Furnace: The Induction System

The entire melting process begins with the generation and application of electromagnetic energy. This is managed by two primary components: the power supply and the induction coils.

The Power Supply: Converting Grid Power to Melting Power

The power supply is the engine of the furnace. It takes standard-frequency electrical current from the grid (typically 50 or 60 Hz) and converts it into a high-frequency alternating current (AC).

This frequency can range from 50 Hz to over 1,000 kHz, depending on the furnace size and application. The ability to precisely control this output is critical for managing the melting rate and the stirring effect within the molten metal.

The Induction Coils: Generating the Magnetic Field

These water-cooled copper coils are the "burners" of the furnace. The high-frequency AC from the power supply runs through them, generating a powerful and rapidly changing magnetic field within the furnace's core.

When a conductive metal charge is placed inside the coils, this magnetic field induces powerful electrical currents—known as eddy currents—within the metal itself. The metal's natural electrical resistance causes these currents to generate intense heat through a process called Joule heating, leading to rapid melting.

Containing the Reaction: The Furnace Core

The core of the furnace is where the intense heat is contained and the metal is held. Its design is critical for both metallurgical quality and the longevity of the equipment.

The Crucible: The Vessel for Molten Metal

The crucible is a high-temperature-resistant container that sits within the induction coils and holds the metal charge. It must be made from a material, typically ceramic or graphite, that can withstand extreme thermal shock and is non-reactive with the specific metal being melted.

Crucially, the crucible material is non-conductive, so the magnetic field passes through it to act directly on the metal charge inside.

The Furnace Body & Vacuum Systems: Controlling the Atmosphere

The coils and crucible are housed within a furnace body. In many advanced applications, this body is a sealed vacuum chamber.

Melting under a vacuum or in a controlled inert atmosphere prevents the molten metal from reacting with oxygen and other atmospheric gases. This is essential for producing high-purity alloys and preventing the loss of valuable alloying elements through oxidation.

Critical Support & Control Systems

To function safely and effectively, the core melting components rely on a suite of essential support systems that manage heat, automation, and safety protocols.

The Cooling System: Preventing Catastrophic Failure

The induction process is so powerful that the copper coils would quickly melt themselves without an active cooling system. A closed-loop water cooling system constantly circulates treated water through the coils and the power supply to dissipate waste heat.

This system is not an accessory; it is fundamental to the furnace's operation and safety. A failure in the cooling circuit would lead to immediate and catastrophic equipment damage.

The Control Panel: The Brains of the Operation

Modern furnaces are governed by a sophisticated control panel or PLC (Programmable Logic Controller). This interface allows operators to set and monitor critical parameters like power level, frequency, and temperature.

It enables a high degree of automation, ensuring consistent, repeatable melting cycles and precise temperature control, which is vital for achieving specific metallurgical properties in the final product.

Integrated Safety Features: The Non-Negotiable Guardian

Safety is paramount. Modern furnaces are equipped with numerous protection mechanisms, including sensors that monitor water flow, temperature, and electrical parameters.

Automatic shut-off systems and emergency stop buttons are standard, designed to immediately de-energize the furnace in the event of a fault, protecting both the operators and the equipment.

Understanding the Trade-offs: Efficiency vs. Capability

Choosing or operating an induction furnace involves balancing competing priorities. The design of its components directly reflects these trade-offs.

A primary consideration is energy efficiency. Induction melting can consume significant power, making efficiency a major driver of operational cost. Optimized coil design, advanced power modulation from the supply, and proper insulation all contribute to reducing energy waste.

Another trade-off involves complexity. A vacuum induction furnace produces exceptionally clean metal but is more expensive to purchase and maintain than an open-air furnace. The vacuum system adds another layer of complexity that is only necessary when alloy purity is the absolute top priority.

Finally, the operating frequency of the power supply is a critical choice. Lower frequencies are better for melting large volumes and promoting a strong stirring action, while higher frequencies are more efficient for smaller melts or specialized heating applications.

Making the Right Choice for Your Application

Understanding these components as an integrated system allows you to align the furnace's capabilities with your specific operational goals.

- If your primary focus is maximum alloy purity: A system with a robust vacuum chamber and precise atmospheric controls is non-negotiable.

- If your primary focus is high-volume production: Prioritize a high-power supply, a durable crucible, and an exceptionally reliable cooling system to handle continuous operation.

- If your primary focus is minimizing operational costs: Look for features like advanced power modulation, energy-efficient coil designs, and superior thermal insulation.

By seeing the furnace as a complete system, you can move beyond a simple list of parts to make truly informed decisions.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Power Supply | Converts grid electricity to high-frequency AC | Precise control of melting rate & stirring |

| Induction Coils | Generate a magnetic field to induce eddy currents | Water-cooled copper construction |

| Crucible | Holds the metal charge during melting | High-temperature resistant (e.g., ceramic, graphite) |

| Cooling System | Removes waste heat from coils and power supply | Closed-loop water circuit; critical for safety |

| Control Panel | Automates and monitors the entire melting process | Ensures consistent, repeatable cycles |

Ready to Optimize Your Melting Process?

Understanding the components is the first step; integrating them into a high-performance system is the next. KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced thermal solutions for laboratories and production facilities.

Our expertise in high-temperature furnace technology, including Vacuum & Atmosphere Furnaces, translates directly into robust induction melting systems. We offer strong deep customization capabilities to precisely meet your unique requirements for alloy purity, production volume, and operational efficiency.

Contact us today to discuss how we can help you build or upgrade a melting system that delivers superior results.

Get in touch via our Contact Form

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries