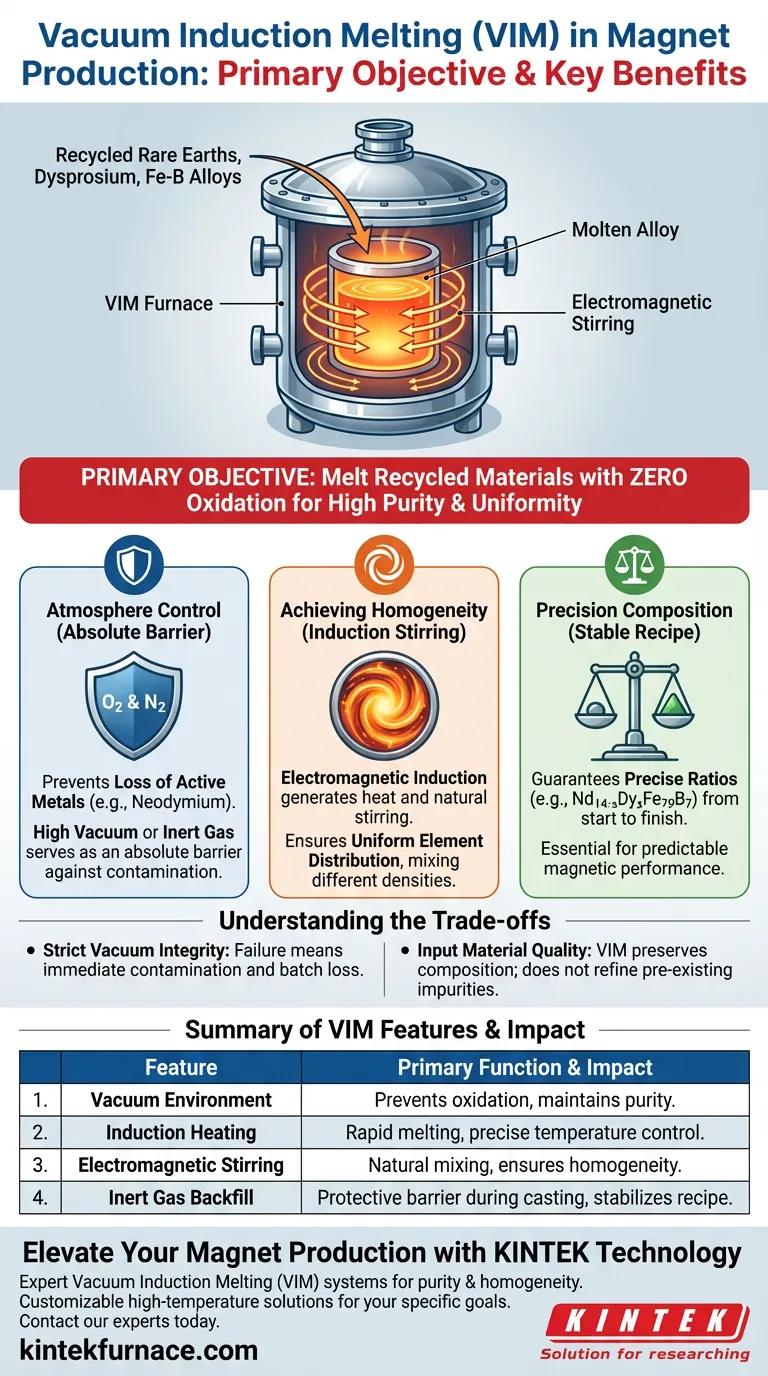

The primary objective of using a Vacuum Induction Melting (VIM) furnace in this stage is to melt recycled rare earth concentrates, supplemental dysprosium, and iron-boron alloys using electromagnetic induction within a protective vacuum environment. This process is specifically designed to prevent the oxidation of highly reactive metals like neodymium, ensuring the final alloy maintains strict chemical uniformity and high purity.

By eliminating atmospheric contact during the melting process, the VIM furnace acts as an absolute barrier against oxidation for reactive rare earth elements. This preservation of purity is the deciding factor in achieving stable magnetic performance in recycled alloys.

The Critical Role of Atmosphere Control

Preventing the Loss of Active Metals

The central challenge in magnet production is the high reactivity of rare earth elements, particularly neodymium. If exposed to oxygen during the high-temperature melting phase, these metals effectively burn off or degrade.

Ensuring an Absolute Barrier

The VIM furnace operates under a high vacuum or an inert gas atmosphere (such as argon). This environment serves as an absolute barrier, preventing oxygen and nitrogen from contaminating the melt and altering the target chemical composition.

Achieving Homogeneity Through Induction

The Mechanism of Electromagnetic Stirring

Beyond simple heating, the VIM furnace utilizes electromagnetic induction to generate heat. A key byproduct of this method is a natural stirring effect within the molten metal.

Uniform Element Distribution

This stirring action is critical for mixing materials with different densities, such as heavy dysprosium and lighter iron-boron alloys. It ensures that the elements are distributed evenly throughout the ingot, creating a consistent chemical base for the magnet.

Precision in Alloy Composition

Stabilizing the Chemical Recipe

The recast stage often involves complex formulas, such as Nd₁₄₋ₓDyₓFe₇₉B₇. The VIM process guarantees that the ratio of these elements remains precise from the start of the melt to the final casting.

Consistency for Downstream Processing

By securing the purity and uniformity of the alloy at this stage, the VIM furnace establishes a high-quality foundation. This consistency is required for predictable results in subsequent thermal processing and magnetic performance evaluations.

Understanding the Trade-offs

The Necessity of Strict Vacuum Integrity

The VIM process is unforgiving regarding equipment integrity. Because the primary goal is oxidation prevention, any failure in the vacuum seal or inert gas backfilling system can result in immediate contamination and the loss of the entire batch of expensive rare earth materials.

Dependence on Input Material Quality

While VIM is excellent at preserving the composition of the input materials, it is primarily a melting and mixing tool, not a refining tool for removing all types of pre-existing impurities. The quality of the final ingot is still heavily dependent on the purity of the recycled concentrates and raw sponges introduced into the furnace.

Making the Right Choice for Your Goal

To maximize the effectiveness of the VIM process in your production line, consider the following specific objectives:

- If your primary focus is Chemical Purity: Prioritize the vacuum level and leak rate integrity of the furnace to ensure zero oxidation of neodymium and dysprosium.

- If your primary focus is Material Homogeneity: Optimize the frequency and power of the induction field to maximize the electromagnetic stirring effect for uniform elemental distribution.

The VIM furnace ultimately transforms volatile, recycled raw ingredients into a stable, high-performance alloy ready for advanced magnet manufacturing.

Summary Table:

| Feature | Primary Function in Magnet Production | Impact on Alloy Quality |

|---|---|---|

| Vacuum Environment | Prevents oxidation of reactive rare earth elements | Maintains chemical purity and prevents material loss |

| Induction Heating | Rapid, efficient melting of recycled concentrates | Precise temperature control for complex recipes |

| Electromagnetic Stirring | Natural mixing of elements with different densities | Ensures uniform distribution (homogeneity) of Dysprosium and Iron-Boron |

| Inert Gas Backfill | Provides a protective barrier during casting | Stabilizes the chemical recipe against atmospheric contamination |

Elevate Your Magnet Production with KINTEK Technology

Precise alloy composition is the cornerstone of high-performance magnet manufacturing. KINTEK provides industry-leading Vacuum Induction Melting (VIM) systems designed to protect your volatile rare earth materials from oxidation while ensuring perfect elemental homogeneity.

Backed by expert R&D and manufacturing, we offer customizable Vacuum, CVD, and high-temperature lab furnaces tailored to your specific chemical purity and material distribution goals. Don't compromise on your alloy quality—contact our technical experts today to discover how our advanced heating solutions can optimize your production line.

Visual Guide

References

- Finks, Christopher. Technical Analysis: Magnet-to-Magnet Rare Earth Recycling Without Solvent Extraction (M2M-Δ Architecture) - Defense Supply Chain Resilience. DOI: 10.5281/zenodo.17625286

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a vacuum environment important in a VIM furnace? Unlock Purity and Performance in Metal Melting

- Why is stainless steel smelted in a vacuum induction melting furnace? Achieve Unmatched Purity and Performance

- What are the advantages of vacuum induction furnace melting for superalloys? Achieve Purity and Performance

- What safety benefits does induction heating provide in the workplace? Achieve a Flameless, Contained Heating Process

- How does the vacuum environment contribute to metal quality in VIM furnaces? Achieve Superior Purity and Performance

- What industries commonly use melt furnaces? Key Applications in Metal, Aerospace, and More

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the function of a VIM furnace for nickel alloys? Secure High-Purity Melting for Extreme Performance