In essence, stainless steel is smelted in a Vacuum Induction Melting (VIM) furnace to achieve a level of purity and metallurgical control that is impossible with conventional air-melting techniques. This process is critical for creating high-performance alloys by systematically removing harmful impurities—particularly dissolved gases like oxygen and nitrogen—which degrade mechanical properties and corrosion resistance.

The primary purpose of using a VIM furnace is not just to melt the metal, but to actively refine it in a controlled vacuum. This environment is the key to removing unwanted elements that would otherwise compromise the integrity of stainless steel in its most demanding applications.

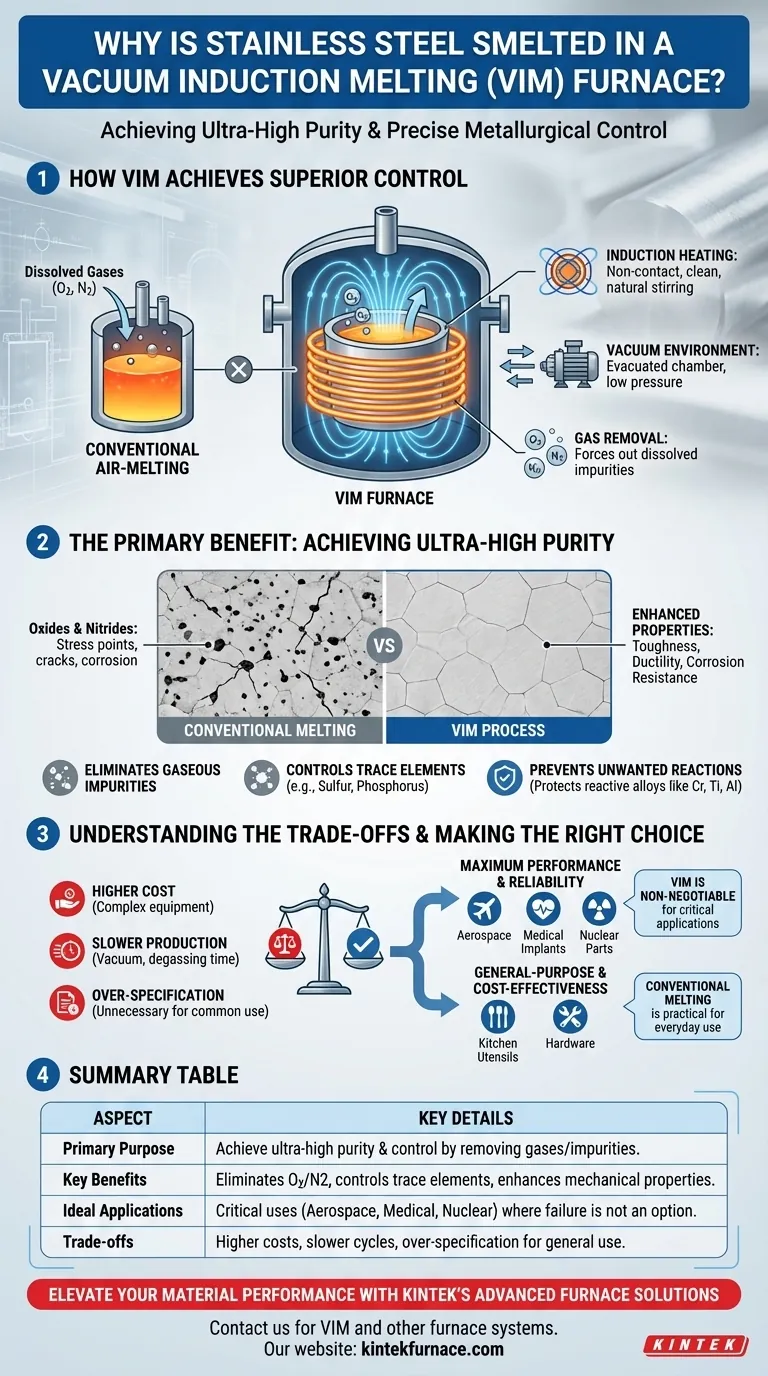

How VIM Achieves Superior Control

The VIM process combines two key technologies—induction heating and a high-vacuum environment—to create an exceptionally clean and precisely controlled melting process.

The Role of Induction Heating

Induction heating uses powerful magnetic fields to generate heat directly within the metal itself. This method is inherently clean, as the material never touches a flame or electric arc.

This non-contact heating allows the metal to be physically isolated from the heating coil. Crucially, it also creates a natural electromagnetic stirring action in the molten bath, which constantly exposes new material to the surface.

The Critical Function of the Vacuum

The furnace chamber is evacuated to a very low pressure. This vacuum environment is the primary driver of the refining process.

By drastically lowering the pressure above the molten steel, it forces dissolved gases like oxygen and nitrogen out of the liquid metal, much like opening a carbonated beverage releases dissolved CO2.

The Primary Benefit: Achieving Ultra-High Purity

The combination of clean heating and a vacuum environment results in a final product with a chemical composition that is both exceptionally pure and precisely controlled.

Eliminating Gaseous Impurities

The most significant benefit of VIM is the removal of dissolved oxygen and nitrogen. In conventional melting, these gases form microscopic non-metallic inclusions (oxides and nitrides).

These inclusions act as stress concentration points within the metal's structure, creating initiation sites for fatigue cracks and corrosion, thereby limiting the material's ultimate performance.

Controlling Volatile Trace Elements

The vacuum environment also helps to remove or control other undesirable trace elements with high vapor pressures, such as sulfur and phosphorus.

By minimizing these impurities, the VIM process significantly enhances the stainless steel's toughness, ductility, and resistance to pitting and crevice corrosion.

Preventing Unwanted Reactions

High-performance stainless steels often contain reactive alloying elements like chromium, titanium, or aluminum.

Melting in a vacuum prevents these valuable and carefully measured elements from reacting with atmospheric oxygen and turning into useless oxides, ensuring they contribute fully to the alloy's intended properties.

Understanding the Trade-offs

While VIM produces superior material, it is a specialized process with clear trade-offs that make it suitable only for specific applications.

Higher Operational Cost

VIM furnaces are significantly more complex and expensive to build and operate than standard air-melt furnaces, due to the need for robust vacuum chambers and pumping systems.

Slower Production Cycles

The process of pulling a vacuum, carefully controlling the melt, and ensuring complete degassing takes considerably more time than a conventional melt. This results in lower throughput and higher per-unit costs.

Over-specification for Common Use

For many everyday applications, such as kitchen utensils, architectural panels, or general-purpose hardware, the extreme purity offered by VIM is unnecessary. The properties of standard air-melted stainless steel are more than sufficient.

Making the Right Choice for Your Goal

The decision to specify a VIM-produced stainless steel hinges entirely on the performance requirements and failure risk of the final component.

- If your primary focus is maximum performance and reliability: VIM is non-negotiable for critical applications like aerospace components, medical implants, or nuclear parts where material failure could be catastrophic.

- If your primary focus is general-purpose use and cost-effectiveness: A conventionally melted and refined stainless steel (such as through an Argon Oxygen Decarburization process) is almost always the more practical and economical choice.

Ultimately, employing vacuum induction melting is a strategic investment in metallurgical certainty for applications where there is no margin for error.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Purpose | Achieve ultra-high purity and precise metallurgical control by removing dissolved gases and impurities. |

| Key Benefits | Eliminates oxygen and nitrogen, controls trace elements, prevents unwanted reactions, and enhances mechanical properties and corrosion resistance. |

| Ideal Applications | Critical uses like aerospace components, medical implants, and nuclear parts where failure is not an option. |

| Trade-offs | Higher costs, slower production cycles, and over-specification for general-purpose applications. |

Elevate Your Material Performance with KINTEK's Advanced Furnace Solutions

Are you working on high-stakes projects in aerospace, medical, or nuclear sectors where material purity and reliability are paramount? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements.

By partnering with us, you'll benefit from:

- Enhanced Material Quality: Achieve superior purity and control in your stainless steel and alloy production.

- Customized Solutions: Tailored furnace designs to fit your specific application needs.

- Reliable Performance: Ensure safety and efficiency in critical environments with our state-of-the-art technology.

Don't compromise on quality—contact us today to discuss how our vacuum induction melting and other furnace systems can drive your innovations forward!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the key benefits of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Alloys

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting