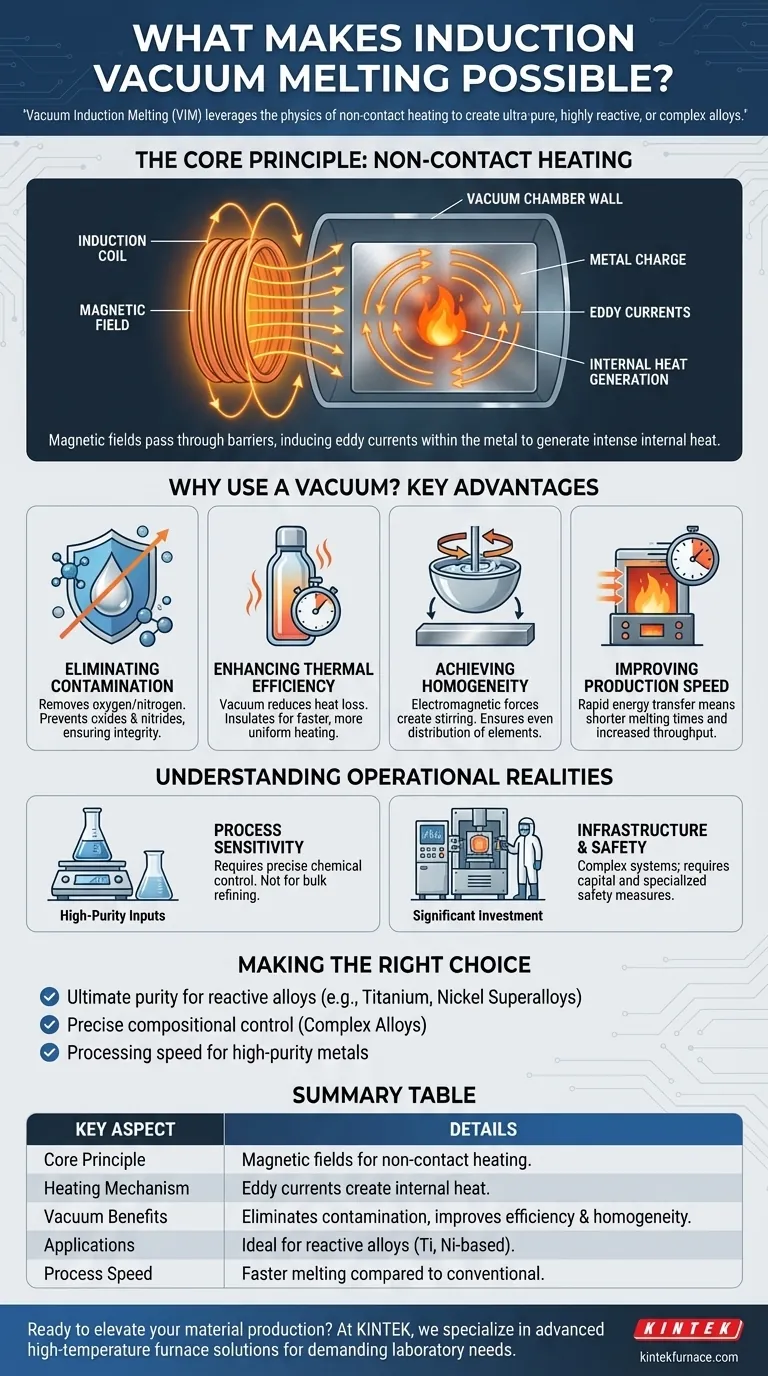

The fundamental principle that makes induction vacuum melting possible is that magnetic fields can pass through physical, non-conductive barriers. This allows an induction coil on the outside of a sealed chamber to generate heat directly within a metal charge on the inside, without any physical contact and in a controlled vacuum environment.

Vacuum Induction Melting (VIM) is not just about melting metal in a void. It is a strategic process that leverages the physics of non-contact heating to create ultra-pure, highly reactive, or complex alloys that would be impossible to produce in the open atmosphere.

The Core Principle: Non-Contact Heating

How Magnetic Fields Enable a Vacuum

An induction heating system uses a powerful alternating current running through a copper coil. This generates a fluctuating magnetic field around the coil.

Because this magnetic field can penetrate non-conductive materials like the ceramic or quartz walls of a vacuum chamber, the heating mechanism is completely separated from the environment.

Inducing Current from a Distance

Once the magnetic field passes through the chamber wall, it interacts with the conductive metal charge inside. The field induces powerful electrical currents, known as eddy currents, directly within the metal.

The metal's own electrical resistance to the flow of these eddy currents generates intense, rapid, and localized heat, causing the charge to melt from the inside out.

Why Use a Vacuum? Key Process Advantages

The ability to heat metal without contact is only half the story. The vacuum environment itself provides critical benefits for advanced material production.

Eliminating Atmospheric Contamination

Many advanced metals and superalloys, such as titanium, nickel, and cobalt-based alloys, are highly reactive with oxygen and nitrogen at high temperatures.

Melting in a vacuum removes these atmospheric gases, preventing the formation of oxides and nitrides that compromise the material's integrity, strength, and performance.

Enhancing Thermal Efficiency

In a standard atmosphere, a significant amount of heat is lost through convection and conduction to the surrounding air. A vacuum, being largely empty of matter, is an excellent insulator.

This lack of air dramatically reduces heat loss, making the melting process more energy-efficient and allowing for faster, more uniform heating of the entire metal charge.

Achieving Compositional Homogeneity

The same electromagnetic forces that generate heat also create a vigorous stirring action within the molten metal bath.

This electromagnetic stirring ensures that all alloying elements are distributed evenly, leading to a perfectly homogenous final product. This is critical for alloys where even minor variations in composition can lead to failure.

Improving Production Speed

Induction furnaces transfer energy into the metal with incredible speed and efficiency. This results in significantly shorter melting times compared to conventional arc or gas-fired furnaces.

Faster cycles not only increase production throughput but also minimize the time the molten metal is exposed to high temperatures, further reducing the risk of unwanted reactions or element loss.

Understanding the Operational Realities

While powerful, the VIM process involves significant complexity and investment. It is not a universal solution for all melting applications.

Process Sensitivity

The VIM process is designed for creating high-value materials from high-purity raw inputs. It is not a refining process for removing bulk impurities from low-grade scrap or ore. The chemistry must be precisely controlled from the start.

Infrastructure and Safety

VIM furnaces are complex systems that operate under extreme conditions of vacuum and temperature. This requires significant capital investment in vacuum pumps, power supplies, and control systems.

Furthermore, worker safety is a major consideration. Facilities are often built inside protective enclosures or tunnels to contain heat and mitigate risks, requiring operators to wear specialized protective gear.

Making the Right Choice for Your Goal

The decision to use Vacuum Induction Melting is driven by the specific requirements of the final material.

- If your primary focus is ultimate purity for reactive alloys: VIM is the industry standard for preventing atmospheric contamination in materials like titanium and nickel-based superalloys.

- If your primary focus is precise compositional control: The electromagnetic stirring inherent to VIM provides unmatched homogeneity for complex, multi-element alloys.

- If your primary focus is processing speed for high-purity metals: The rapid heating and high thermal efficiency of VIM offer significant advantages in production throughput.

Ultimately, Vacuum Induction Melting is the definitive solution when the material's performance depends on absolute purity and precise chemical control.

Summary Table:

| Key Aspect | Details |

|---|---|

| Core Principle | Magnetic fields pass through barriers for non-contact heating |

| Heating Mechanism | Eddy currents induced in metal generate internal heat |

| Vacuum Benefits | Eliminates contamination, improves thermal efficiency, ensures homogeneity |

| Applications | Ideal for reactive alloys like titanium and nickel-based superalloys |

| Process Speed | Faster melting times compared to conventional methods |

Ready to elevate your material production with precision and purity? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored for demanding laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working with reactive alloys or need precise compositional control, our expertise ensures optimal performance and efficiency. Contact us today to discuss how we can support your goals with cutting-edge technology and customized solutions!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity