The primary advantages of an IGBT induction melting furnace are its superior energy efficiency, faster and more consistent melting speeds, and minimal electrical interference with your facility's power grid. Unlike older technologies, these modern furnaces use Insulated Gate Bipolar Transistors (IGBTs) to deliver constant power throughout the melt cycle, resulting in significant operational and financial benefits.

The core difference is not just an upgrade in components, but a fundamental shift in performance. While older SCR-based furnaces present trade-offs between speed, efficiency, and grid stability, IGBT technology is engineered to deliver all three simultaneously, lowering total cost of ownership and increasing productivity.

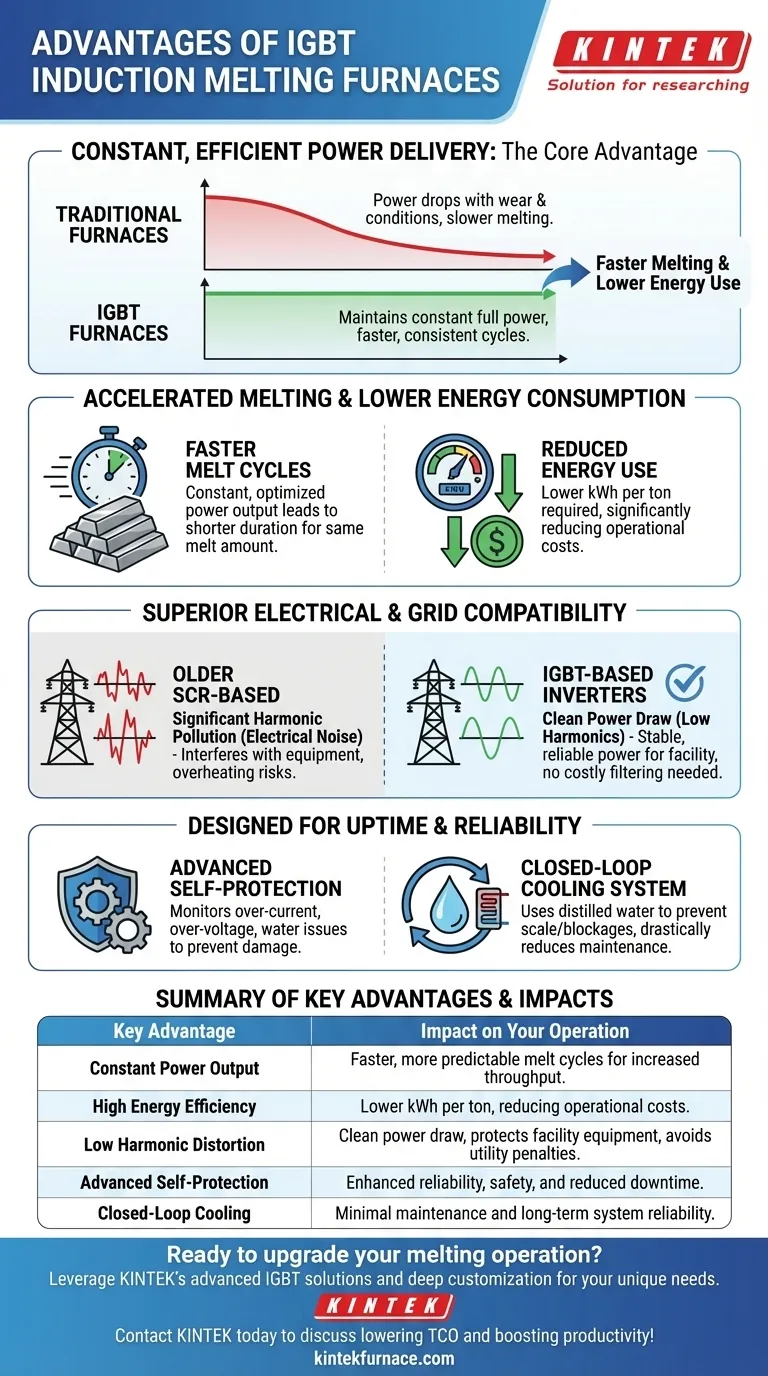

The Core Advantage: Constant, Efficient Power Delivery

The most significant benefit of an IGBT furnace stems from its ability to maintain full power output from the beginning to the end of the melting process. This capability has a direct impact on both speed and cost.

How Constant Power Accelerates Melting

Traditional furnaces often experience a drop in power as the furnace lining wears or as the properties of the metal charge change during heating.

IGBT furnaces, however, utilize a series resonant circuit that maintains a constant, optimized power output regardless of these conditions. This results in faster, more predictable melt cycles.

This consistent and rapid heating is especially valuable for melting stainless steel, copper, aluminum, and precious metals like gold, where uniform temperature is key to quality.

The Impact on Energy Consumption

Faster melting directly translates to lower energy consumption. Because the furnace operates at peak efficiency for a shorter duration to melt the same amount of metal, the overall kilowatt-hours (kWh) required per ton are noticeably reduced.

This efficiency is a key driver for lowering the ongoing operational costs of a foundry or casting facility.

Superior Electrical and Grid Compatibility

A major, often overlooked, advantage of IGBT technology is how cleanly it operates within a facility's electrical ecosystem.

Understanding Harmonic Pollution

Older power supplies, particularly those using Silicon Controlled Rectifiers (SCRs), are known for creating significant "electrical noise," or harmonic distortion, on the power grid.

This pollution can interfere with other sensitive electronic equipment in your factory, cause transformers to overheat, and lead to penalties from your utility provider.

The IGBT Solution: A Clean Power Draw

IGBT-based inverters produce extremely low harmonic distortion. This means they draw power cleanly without disrupting your grid or affecting other machinery.

This eliminates the need for expensive harmonic filtering equipment and ensures stable, reliable power for your entire operation.

Effortless Startup and Operation

IGBT furnaces utilize zero-voltage sweep software, allowing them to start reliably and quickly under full load. This eliminates the startup difficulties common in older SCR systems.

This feature is particularly beneficial for operations that require frequent stops and starts, enhancing overall productivity.

Designing for Uptime and Reliability

Modern IGBT furnaces are engineered not just for performance, but for durability and ease of use, minimizing costly downtime.

Advanced Self-Protection Systems

These furnaces are equipped with comprehensive protection functions. They constantly monitor for over-current, over-voltage, water pressure issues, and short circuits.

These systems automatically protect the equipment from damage, ensuring operational safety and preserving the longevity of the power supply and furnace components.

The Importance of a Closed-Loop Cooling System

A common point of failure in any induction system is cooling. IGBT furnaces typically use a sealed, closed-loop water circulation system with distilled water.

This design, often paired with a heat exchanger, prevents the buildup of scale and blockages common with untreated water. The result is drastically reduced maintenance and higher long-term reliability.

Modern Control and Automation

Controlled by advanced digital processors (DSPs), these furnaces offer precise control over the melting process. Many feature simple interfaces, like one-button operation, and provide communication ports for remote monitoring and control.

Understanding the Trade-offs

While the advantages are significant, a complete technical evaluation requires acknowledging the trade-offs.

Initial Investment Cost

An IGBT furnace often has a higher upfront purchase price compared to a new or refurbished SCR-based system. The decision must be weighed against the lower long-term operating costs from energy savings and reduced maintenance.

Complexity of Repair

The advanced solid-state electronics in an IGBT power supply are highly reliable. However, if a fault does occur, troubleshooting and repairing a sophisticated control board or IGBT module may require a more specialized technician than servicing a simpler, older SCR circuit.

Making the Right Choice for Your Operation

Your decision should be guided by your specific operational priorities.

- If your primary focus is minimizing operating costs: The IGBT furnace's superior energy efficiency and reduced maintenance needs will deliver a lower total cost of ownership over the equipment's lifespan.

- If your primary focus is maximizing production throughput: The constant power output and rapid, predictable melt cycles directly increase your plant's output capacity and scheduling reliability.

- If your primary focus is operational stability and future-proofing: The near-zero harmonic pollution of an IGBT system is a critical advantage, protecting your entire facility and ensuring compliance with modern power quality standards.

Ultimately, adopting an IGBT furnace is an investment in a more productive, efficient, and reliable melting operation.

Summary Table:

| Key Advantage | Impact on Your Operation |

|---|---|

| Constant Power Output | Faster, more predictable melt cycles for increased throughput. |

| High Energy Efficiency | Lower kWh per ton, reducing operational costs. |

| Low Harmonic Distortion | Clean power draw, protects facility equipment, avoids utility penalties. |

| Advanced Self-Protection | Enhanced reliability, safety, and reduced downtime. |

| Closed-Loop Cooling | Minimal maintenance and long-term system reliability. |

Ready to upgrade your melting operation with a high-performance, cost-effective solution?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides foundries and metal casting facilities with advanced IGBT induction melting furnace solutions. Our product line, including customized systems for stainless steel, copper, aluminum, and precious metals, is complemented by our strong deep customization capability to precisely meet your unique production requirements and maximize your return on investment.

Contact KINTEL today to discuss how our IGBT technology can lower your total cost of ownership and boost your productivity!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What are the advantages of vacuum induction melting? Achieve Superior Purity for High-Performance Alloys

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance