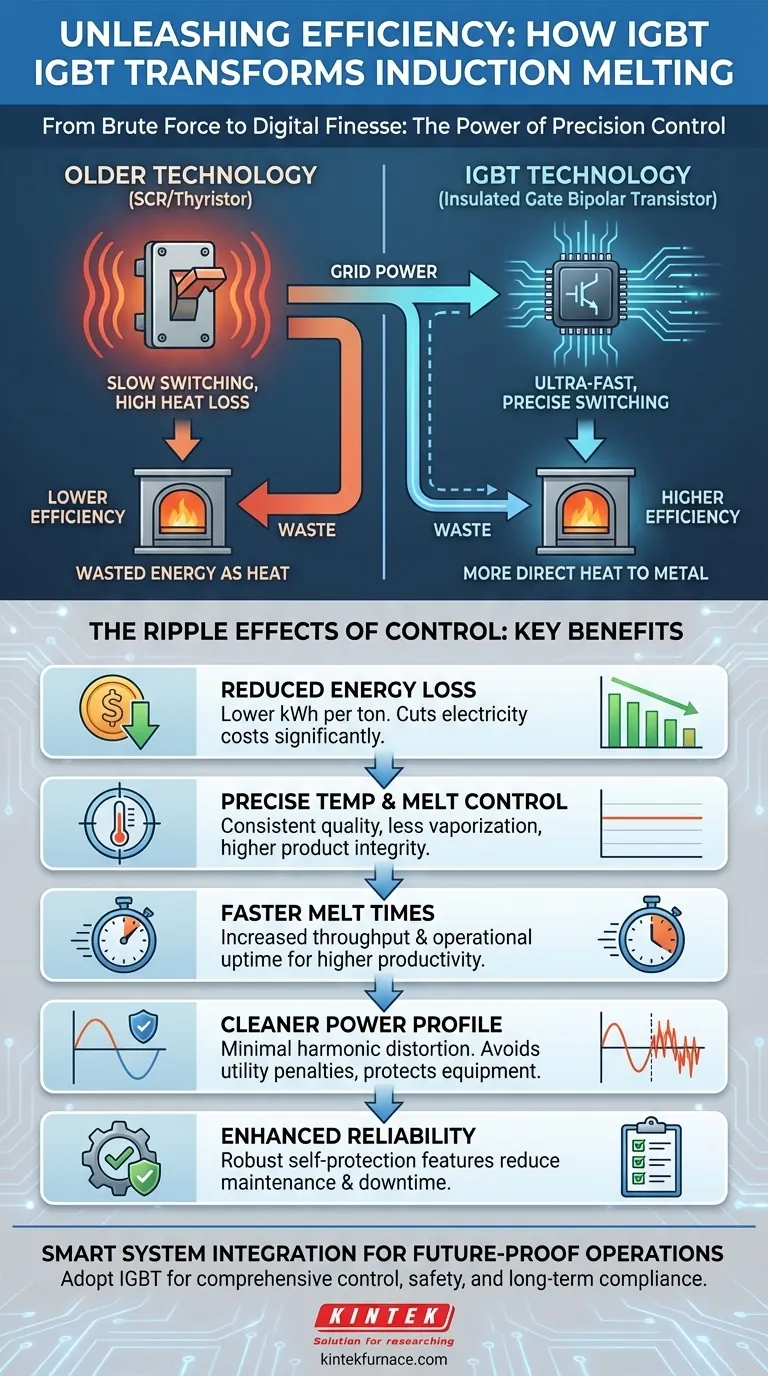

At its core, an IGBT-based induction melting furnace enhances efficiency by functioning as an extremely fast and precise electronic switch. Unlike older technologies that waste significant energy as heat during power regulation, the Insulated Gate Bipolar Transistor (IGBT) minimizes this switching loss, ensuring more of the electrical power drawn from the grid is converted directly into useful heat in the metal charge. This fundamental improvement in power conversion is the primary driver of energy savings.

The crucial insight is that IGBT technology isn't just a component upgrade; it represents a superior method of power control. This precision control delivers a cascade of benefits beyond simple energy savings, impacting melt quality, operational speed, and overall system reliability.

The Core Mechanism: From Crude Power to Precision Control

To understand the impact of IGBTs, it's helpful to compare them to the less efficient technologies they replace. The story is one of moving from a brute-force approach to one of digital finesse.

What is an IGBT? A Hybrid Powerhouse

An IGBT, or Insulated Gate Bipolar Transistor, is a modern semiconductor device that acts as a high-speed switch. It combines the low power-draw control of a MOSFET with the high-current handling capability of a bipolar transistor.

In an induction furnace, its job is to turn the high-power current flowing to the induction coil on and off thousands of times per second. By precisely controlling the timing of these switches, it regulates the exact amount of energy delivered to the melt.

The Problem with Older Technologies

Many older induction furnaces use Silicon Controlled Rectifiers (SCRs), also known as thyristors. While effective, SCRs are inherently less efficient switches.

They are slower to react and generate more waste heat during operation. Think of it as a rheostat or a light dimmer that gets hot as you dim the lights—that heat is wasted energy. This inefficiency means a portion of your electricity bill is spent heating the power supply unit itself, not your metal.

How IGBTs Minimize Energy Loss

IGBTs operate with significantly lower switching losses. Because they can turn on and off almost instantaneously, the transition period where energy can be wasted as heat is dramatically reduced.

This means a much higher percentage of electrical energy is successfully converted into the high-frequency power needed for induction heating. The result is a direct reduction in kilowatt-hours (kWh) consumed per ton of melted metal.

Beyond Energy Savings: The Ripple Effects of Control

The efficiency of an IGBT system creates benefits that extend throughout the entire melting operation, addressing quality, productivity, and infrastructure concerns.

Unmatched Temperature and Melt Control

The high-speed switching of an IGBT allows for incredibly precise power regulation. This gives operators fine-grained control over the melting process, enabling them to maintain an exact temperature.

This precision prevents overheating, reduces metal loss due to vaporization (burn-off), and ensures consistent metallurgical properties in the final product. The result is higher quality castings and less wasted material.

Faster Melt Times and Increased Throughput

Because more power is directed into the charge and less is wasted, IGBT furnaces often achieve faster melting times.

Getting the furnace to temperature more quickly and completing the melt cycle faster directly translates to increased operational uptime and higher production throughput for the facility.

Cleaner Power and Lower Harmonic Pollution

A significant, often overlooked, benefit is the reduction of harmonic distortion. Older SCR-based systems are known for injecting "dirty power" back into the electrical grid.

This electrical noise can interfere with other sensitive electronic equipment in the plant and may lead to financial penalties from the utility provider. IGBT power supplies run inherently cleaner, protecting your other equipment and ensuring compliance with power quality standards.

Understanding the Operational Realities

While the benefits are substantial, a complete technical assessment requires acknowledging the full picture, including maintenance and system design.

Increased Reliability and Uptime

Modern IGBT systems are designed with robust components and self-protection functions. They can intelligently monitor for conditions like over-voltage or short circuits, shutting down safely to prevent catastrophic failure.

This reliability, coupled with reduced thermal stress on the power supply components, leads to less maintenance, fewer breakdowns, and more predictable production schedules.

The Importance of System Integration

The true performance of an IGBT furnace relies on the entire system. The "smart controller," high-quality capacitors, and an efficient cooling system are just as critical as the IGBTs themselves.

A well-designed system ensures the IGBTs operate within their ideal temperature and voltage range, maximizing their lifespan and efficiency.

Making the Right Choice for Your Operation

Choosing the right technology depends on your primary operational goals. The decision to invest in an IGBT furnace is a strategic one that pays dividends in multiple areas.

- If your primary focus is minimizing operating costs: IGBT is the definitive choice due to its superior energy efficiency, reduced maintenance needs, and lower risk of utility penalties.

- If your primary focus is maximizing melt quality and consistency: The precise temperature and power control offered by IGBT systems provides unparalleled metallurgical accuracy and repeatability.

- If your primary focus is increasing plant throughput: IGBT furnaces deliver faster melt cycles, directly boosting the amount of metal you can process in a day.

- If your primary focus is future-proofing your facility: IGBT technology is the current standard, offering lower harmonic distortion and greater control, ensuring your operation remains efficient and compliant for years to come.

Ultimately, adopting IGBT technology is an investment in comprehensive control over the entire melting process.

Summary Table:

| Key Benefit | Impact on Your Operation |

|---|---|

| Reduced Energy Loss | Lower kWh per ton of melted metal, cutting electricity costs. |

| Precise Temperature Control | Consistent melt quality, less metal vaporization, and higher product integrity. |

| Faster Melt Times | Increased throughput and operational uptime for higher productivity. |

| Cleaner Power Profile | Minimal harmonic distortion, avoiding utility penalties and protecting equipment. |

| Enhanced Reliability | Robust self-protection features reduce maintenance and downtime. |

Ready to upgrade your melting process with IGBT efficiency? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by deep customization capabilities to meet your unique experimental and production requirements. Contact us today to explore how our IGBT-based induction melting systems can drive energy savings, improve melt quality, and boost your facility's productivity!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications