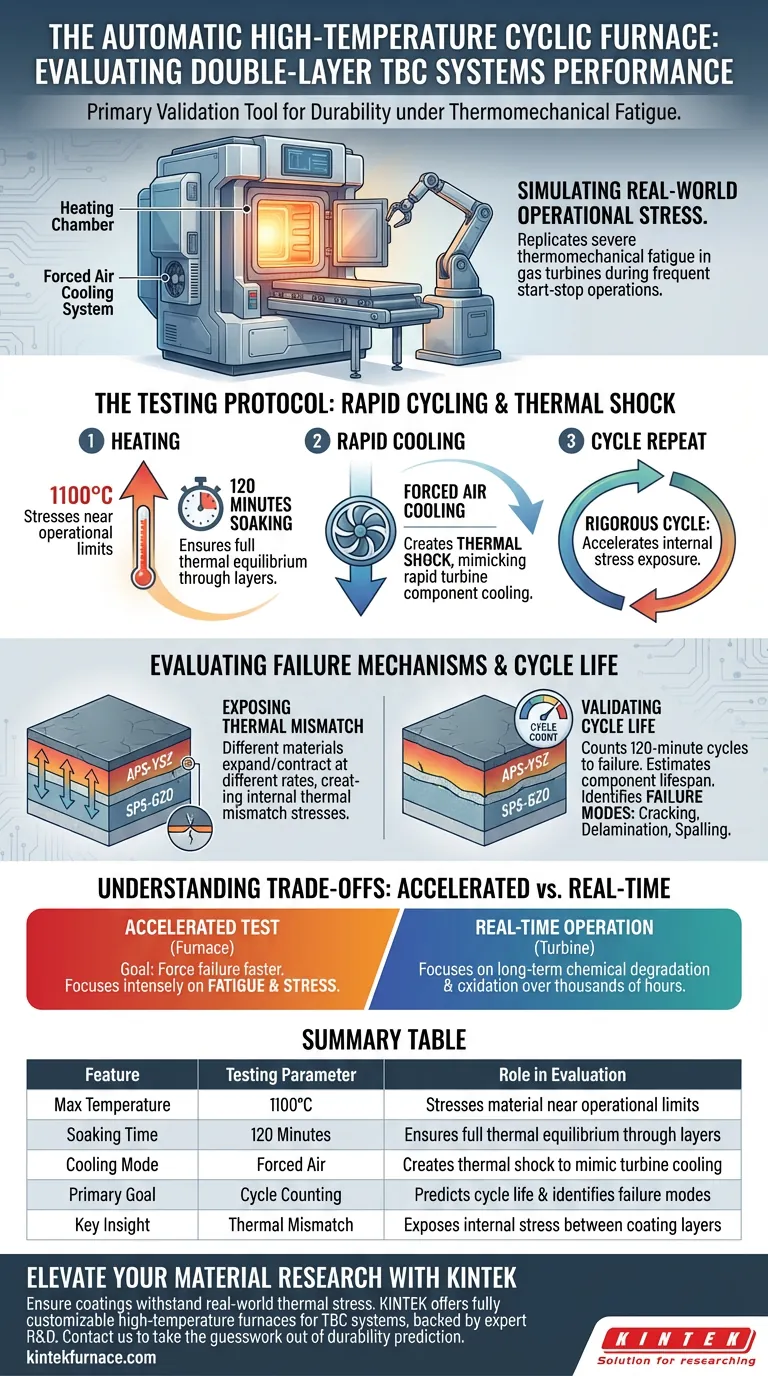

An automatic high-temperature cyclic furnace acts as the primary validation tool for determining the durability of double-layer Thermal Barrier Coating (TBC) systems under stress. Its specific role is to simulate the severe thermomechanical fatigue that occurs in gas turbines during frequent start and stop operations.

The furnace subjects the coating to a rigorous cycle of heating to 1100°C, holding for 120 minutes, and rapid forced air cooling. This process accelerates the exposure of internal stresses, allowing engineers to accurately predict the cycle life and failure modes of complex structures.

Simulating Real-World Operational Stress

Replicating Gas Turbine Cycles

In real-world applications, gas turbines do not always operate at a constant temperature. They undergo frequent operational changes.

The automatic cyclic furnace is designed to replicate these specific start-stop environments. Instead of testing mere heat resistance, it tests the material's ability to withstand constant fluctuation.

The Role of Thermal Shock

The most critical function of the furnace is the application of forced air cooling after a period of intense heat.

This rapid change creates a thermal shock effect. It mimics the rapid cooling a turbine component might experience, which is often far more damaging than the heating phase itself.

The Testing Protocol

Precise Temperature Parameters

To ensure standardized results, the furnace controls the heating process with high precision.

The standard protocol involves bringing the system to 1100°C. This temperature is sufficient to stress the materials near their operational limits without immediately melting them.

Thermal Soaking

Once the target temperature is reached, the furnace maintains it for a holding period of 120 minutes.

This duration ensures the heat penetrates through the double-layer structure completely. It guarantees that the entire system, not just the surface, reaches thermal equilibrium before the cooling phase begins.

Evaluating Failure Mechanisms

Exposing Thermal Mismatch

Double-layer systems, such as APS-YSZ/SPS-GZO, consist of different materials layered together. These materials expand and contract at different rates.

The cyclic nature of the furnace accelerates the development of internal thermal mismatch stresses. This reveals how well the layers stay bonded when they are fighting against each other's expansion rates.

Validating Cycle Life

The ultimate output of this testing is the determination of the TBC's cycle life.

By counting how many 120-minute cycles the coating can withstand before failure, engineers can estimate the component's lifespan in the field. It also identifies the specific failure modes—whether the coating cracks, delaminates, or spalls.

Understanding the Trade-offs

Accelerated vs. Real-Time Testing

It is important to recognize that this method is an accelerated test.

The goal is to force failure faster than it would occur in a turbine operating under normal conditions. While this saves time, it focuses intensely on fatigue and stress rather than long-term chemical degradation or oxidation that might occur over thousands of hours of steady-state operation.

Making the Right Choice for Your Goal

When evaluating TBC systems, understanding the intent of the cyclic furnace is key to interpreting your data.

- If your primary focus is Durability Prediction: Look at the total cycle life number to estimate how many start-stop cycles the component can endure before replacement.

- If your primary focus is Material Development: Analyze the failure modes exposed by the thermal mismatch to adjust the composition or thickness of your APS-YSZ or SPS-GZO layers.

By rigorously stressing the interface between layers, the automatic high-temperature cyclic furnace provides the definitive verdict on a coating's mechanical reliability.

Summary Table:

| Feature | Testing Parameter | Role in Evaluation |

|---|---|---|

| Max Temperature | 1100°C | Stresses material near operational limits |

| Soaking Time | 120 Minutes | Ensures full thermal equilibrium through layers |

| Cooling Mode | Forced Air | Creates thermal shock to mimic turbine cooling |

| Primary Goal | Cycle Counting | Predicts cycle life and identifies failure modes |

| Key Insight | Thermal Mismatch | Exposes internal stress between coating layers |

Elevate Your Material Research with KINTEK

Ensure your coatings can withstand the rigors of real-world thermal stress. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our high-temperature furnaces are fully customizable to meet your unique testing protocols for TBC systems and beyond. Contact us today to find the perfect furnace for your lab and take the guesswork out of durability prediction.

Visual Guide

References

- Jens Igel, Robert Vaßen. Extended Lifetime of Dual-Layer Yttria-Stabilized Zirconia APS/Gadolinium Zirconate SPS Thermal Barrier Coatings in Furnace Cycle Tests. DOI: 10.3390/coatings14121566

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the temperature of a graphite furnace? Unlock Extreme Heat Up to 3000°C

- What role does a high-performance blast drying oven play in the hydrothermal reaction stage of CoO/CoSe nanoparticles?

- What is the purpose of equipping the condensation section of a sodium heat pipe with a specialized insulation cover?

- Why is a pressurized environment necessary for HMF synthesis? Ensure Liquid Phase Stability at High Temperatures

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing

- What is the role of a dedicated bias power supply in low-pressure plasma nitriding? Master Ion Acceleration Control

- Why is a precision constant temperature drying oven required for the impregnation modification process of activated carbon?

- How do thermal systems reveal anti-spalling mechanisms in CDE concrete? Explore Advanced Material Resilience