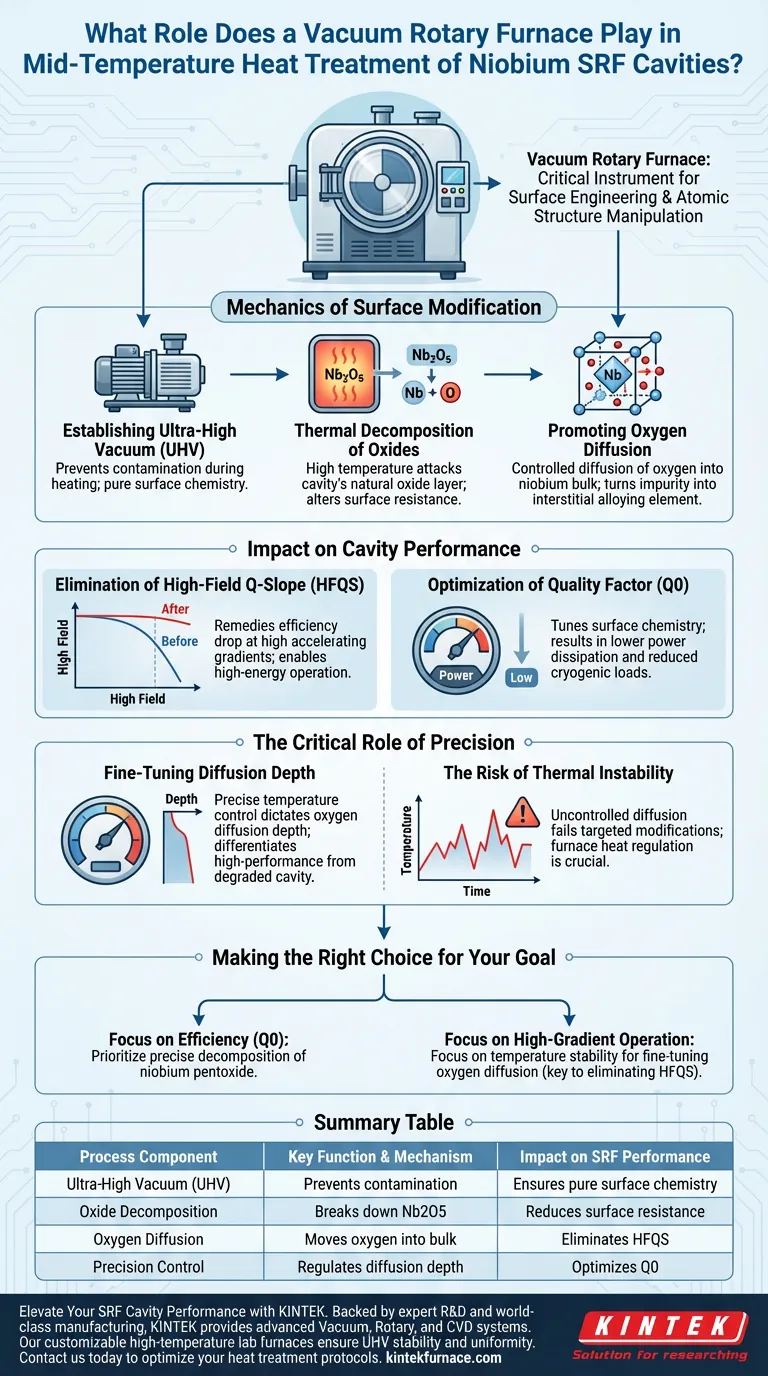

A Vacuum Rotary Furnace is the critical instrument for optimizing the surface chemistry of niobium superconducting radio frequency (SRF) cavities during mid-temperature heat treatment. It functions by establishing an ultra-high vacuum (UHV) environment that allows for the precise thermal decomposition of surface oxides and the controlled diffusion of oxygen into the bulk niobium.

The furnace is more than a heating element; it is a surface engineering tool designed to manipulate atomic structures. By managing oxygen diffusion depths, it solves the "high-field Q-slope" problem and significantly boosts the cavity's quality factor ($Q_0$).

The Mechanics of Surface Modification

Establishing an Ultra-High Vacuum (UHV)

The primary baseline for this process is the creation of an ultra-high vacuum environment.

This vacuum is essential to prevent external contaminants from reacting with the niobium while it is in a heated, highly reactive state. It ensures that the changes to the cavity surface are driven solely by controlled thermal processes, not by impurities in the atmosphere.

Thermal Decomposition of Oxides

The furnace utilizes high temperatures to attack the cavity's natural oxide layer.

Specifically, the heat drives the thermal decomposition of niobium pentoxide ($Nb_2O_5$). This oxide layer, which naturally forms on the surface, is broken down systematically to alter the surface resistance properties of the material.

Promoting Oxygen Diffusion

Once the oxide layer decomposes, the oxygen atoms do not simply vanish.

Instead, the furnace environment promotes the diffusion of this oxygen into the niobium bulk. This turns a surface impurity into an interstitial alloying element, effectively modifying the superconducting properties of the material just below the surface.

Impact on Cavity Performance

Elimination of High-Field Q-Slope (HFQS)

One of the most significant roles of this heat treatment is the remediation of specific performance drops.

Standard niobium cavities often suffer from a sharp drop in efficiency at high accelerating gradients, known as the high-field Q-slope. The vacuum rotary furnace treatment effectively eliminates this phenomenon, allowing the cavity to perform efficiently at higher energy levels.

Optimization of Quality Factor ($Q_0$)

Beyond fixing specific defects, the process improves overall efficiency.

By tuning the surface chemistry, the treatment optimizes the quality factor ($Q_0$). This results in lower power dissipation and reduced cryogenic loads during the operation of the accelerator.

The Critical Role of Precision

Fine-Tuning Diffusion Depth

Success in this process is not binary; it depends entirely on the depth of the oxygen profile.

The furnace must provide precise temperature control to dictate exactly how deep the oxygen diffuses. This "fine-tuning" is the difference between a high-performance cavity and a degraded one.

The Risk of Thermal Instability

If the furnace cannot maintain strict temperature stability, the diffusion process becomes unpredictable.

An uncontrolled diffusion depth fails to achieve the targeted surface resistance modifications. Therefore, the furnace's ability to regulate heat is as important as its ability to generate it.

Making the Right Choice for Your Goal

To maximize the benefits of mid-temperature heat treatment, consider your specific performance objectives:

- If your primary focus is Efficiency ($Q_0$): Ensure your furnace protocols prioritize the precise decomposition of niobium pentoxide to minimize surface resistance.

- If your primary focus is High-Gradient Operation: Focus on the temperature stability required to fine-tune oxygen diffusion, which is the key mechanism for eliminating the high-field Q-slope.

The Vacuum Rotary Furnace is the bridge between raw niobium fabrication and high-performance superconducting operation.

Summary Table:

| Process Component | Key Function & Mechanism | Impact on SRF Performance |

|---|---|---|

| Ultra-High Vacuum (UHV) | Prevents contamination during heating | Ensures pure surface chemistry |

| Oxide Decomposition | Breaks down Niobium Pentoxide ($Nb_2O_5$) | Reduces surface resistance |

| Oxygen Diffusion | Moves oxygen into the bulk material | Eliminates high-field Q-slope (HFQS) |

| Precision Control | Regulates diffusion depth via temperature | Optimizes quality factor ($Q_0$) |

Elevate Your SRF Cavity Performance with KINTEK

Precision is non-negotiable when engineering superconducting surfaces. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Vacuum, Rotary, and CVD systems designed to meet the rigorous thermal demands of SRF research and production.

Our customizable high-temperature lab furnaces ensure the UHV stability and temperature uniformity required to eliminate HFQS and maximize your quality factor. Whether you are scaling production or fine-tuning diffusion depths, KINTEK delivers the reliability your laboratory needs.

Ready to optimize your heat treatment protocols? Contact us today to discuss your unique requirements with our technical specialists.

Visual Guide

References

- Christopher Bate, Jacob Wolff. Correlation of srf performance to oxygen diffusion length of medium temperature heat treated cavities<sup>*</sup>. DOI: 10.1088/1361-6668/ad9fe8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the key advantages of using rotary kilns? Achieve High-Volume, Uniform Thermal Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What is the basic structure and operation principle of a rotary furnace? Master Continuous Thermal Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the use of a rotary furnace? Achieve Uniform Heating & Mixing for Industrial Materials

- What role does gas flow and combustion play in a rotary kiln? Optimize Heat Transfer for Efficiency and Quality

- What environmental applications utilize rotary kilns? Transform Waste into Value with Precision

- How do rotary kilns contribute to chemical and mineral processing? Unlock Efficiency and Sustainability