At its core, a rotary kiln excels due to three primary advantages: its remarkable versatility in processing a wide range of materials, its ability to achieve uniform heat distribution for consistent product quality, and its capacity for continuous, high-volume throughput. These attributes make it an indispensable tool for countless industrial thermal processes, from cement production to waste reclamation.

A rotary kiln is more than just a high-temperature furnace; it is a dynamic processing environment. Its fundamental advantage lies in using continuous rotation to simultaneously convey, mix, and uniformly heat material, ensuring a consistent, high-quality final product at an industrial scale.

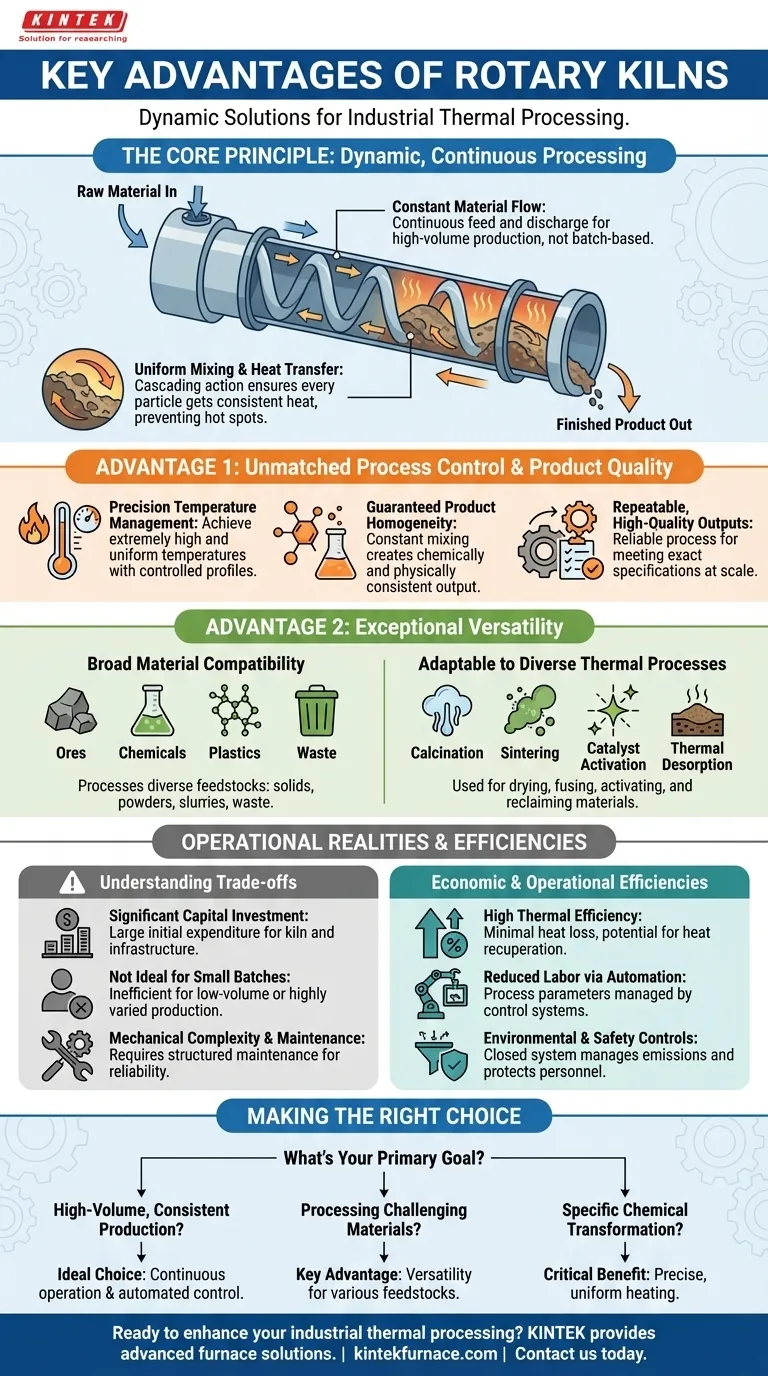

The Core Principle: Dynamic, Continuous Processing

To understand the advantages of a rotary kiln, you must first understand its basic function. It is a large, rotating cylindrical vessel, angled slightly to allow gravity to move material from one end to the other as it turns.

Constant Material Flow

This design facilitates continuous processing, where raw material is constantly fed into the upper end and a finished product is constantly discharged at the lower end. This is a stark contrast to batch-based systems, enabling consistent, high-volume production.

Uniform Mixing and Heat Transfer

The slow, constant rotation tumbles the material, much like a clothes dryer. This action, known as cascading, continuously exposes new surfaces to the heat source. This ensures every particle experiences nearly identical process conditions, preventing hot spots and guaranteeing uniform heat transfer.

Key Advantage 1: Unmatched Process Control and Product Quality

The dynamic environment inside a kiln allows for an exceptionally high degree of control over the final product.

Precision Temperature Management

Rotary kilns can achieve extremely high and uniform temperatures. Their design allows for precise control over the temperature profile along the length of the kiln, which is critical for complex processes that require specific heating, soaking, and cooling stages.

Guaranteed Product Homogeneity

The constant tumbling and mixing action is the single most important factor for product homogeneity. It ensures that the final output is chemically and physically consistent, a non-negotiable requirement in applications like cement, catalysts, and activated carbon.

Repeatable, High-Quality Outputs

The combination of continuous flow, automation, and precise temperature control means rotary kilns deliver repeatable results. This reliability is crucial for industrial applications where product specifications must be met consistently across millions of tons of material.

Key Advantage 2: Exceptional Versatility

Rotary kilns are not specialized for a single task; they are adaptable workhorses used across dozens of industries.

Broad Material Compatibility

A key strength is the ability to process a vast array of feedstocks. This includes everything from granular solids and powders to slurries and waste streams. They are used for ores, minerals, chemicals, plastics, agricultural products, and hazardous waste, among others.

Adaptable to Diverse Thermal Processes

This material versatility extends to process versatility. Kilns are used for calcination (heating to drive off moisture or CO2), sintering (heating to fuse particles), catalyst activation, and thermal desorption (reclaiming contaminated soils).

Understanding the Trade-offs and Operational Realities

While powerful, rotary kilns are not a universal solution. Understanding their limitations is critical for making an informed decision.

Significant Capital Investment

Rotary kilns are large, heavy, and complex pieces of industrial machinery. The initial capital expenditure for the kiln and its supporting infrastructure (feed systems, off-gas handling, etc.) is substantial.

Not Ideal for Small Batch Processing

The continuous nature that makes kilns efficient for high volumes becomes a disadvantage for small, distinct batches. The time required to heat up, cool down, and clean the system between different product runs makes it inefficient for low-volume or highly varied production.

Mechanical Complexity and Maintenance

A rotating, high-temperature vessel is a demanding mechanical system. While modern kilns have long service lives, they require a structured maintenance program for components like the drive system, support rollers, and refractory lining to ensure reliability.

Operational and Economic Efficiencies

When properly matched to an application, a rotary kiln provides significant long-term economic benefits.

High Thermal and Energy Efficiency

Modern kilns are designed to minimize heat loss, with some achieving thermal efficiency as high as 95%. This direct heating method and the potential for recuperating heat from exhaust gases and the product itself can make them more economical to operate than other systems.

Reduced Labor through Automation

Contemporary rotary kiln systems feature a high degree of automation. Process parameters like feed rate, rotation speed, and temperature are managed by control systems, significantly reducing the need for constant operator intervention and lowering labor costs.

Environmental and Safety Controls

As a closed system, a rotary kiln provides excellent control over process emissions. Off-gases can be routed through filtration and scrubbing systems to meet strict environmental regulations, and comprehensive safety interlocks protect both personnel and equipment.

Making the Right Choice for Your Application

Selecting a rotary kiln depends entirely on your primary processing goal.

- If your primary focus is high-volume production of a consistent product: The kiln's continuous operation and automated process control make it the ideal choice.

- If your primary focus is processing challenging or diverse materials: The kiln's versatility in handling various feedstocks from powders to slurries is its key advantage.

- If your primary focus is achieving a specific chemical or physical transformation: The kiln's ability to provide precise, uniform heating is critical for producing materials with exacting specifications.

Ultimately, the rotary kiln remains a cornerstone of modern industry because it reliably solves the core challenge of transforming bulk materials with heat at scale.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Continuous Processing | High-volume, consistent output | Cement production, large-scale manufacturing |

| Uniform Heat Distribution | Consistent product quality | Catalyst activation, material sintering |

| Versatility | Handles diverse materials | Ores, chemicals, hazardous waste processing |

| Process Control | Precision temperature management | Complex thermal processes requiring specific stages |

| Economic Efficiency | High thermal efficiency and automation | Reducing operational costs and labor |

Ready to enhance your industrial thermal processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can optimize your production efficiency and product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results