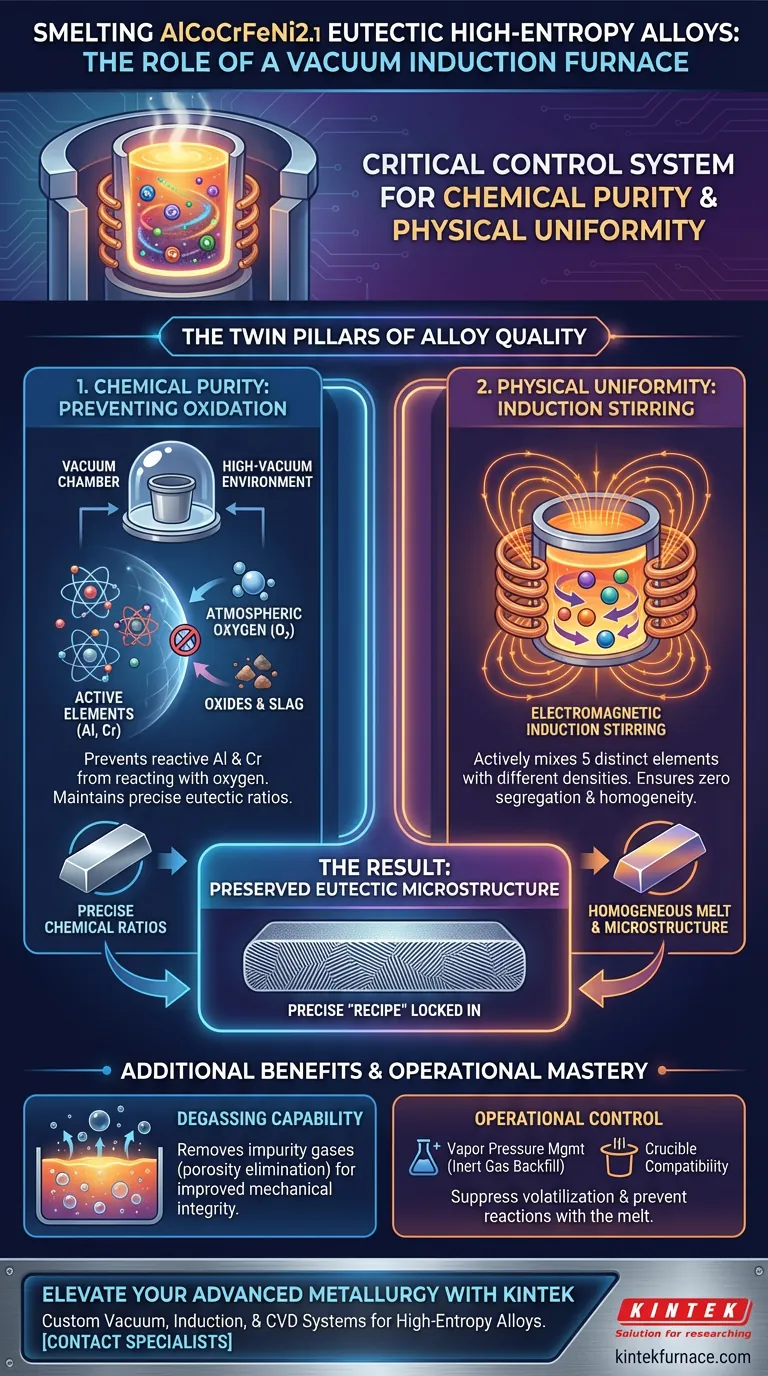

A vacuum induction furnace acts as the critical control system for both chemical purity and physical uniformity in the smelting of AlCoCrFeNi2.1.

By establishing a high-vacuum environment, the furnace prevents the oxidative loss of reactive elements like aluminum and chromium. Simultaneously, it utilizes electromagnetic induction to actively stir the molten metal, forcing the five distinct elements to mix thoroughly into a precise, homogeneous alloy.

The core function of the vacuum induction furnace is to eliminate atmospheric contamination while mechanically homogenizing the melt, ensuring the strict chemical ratios required to achieve the eutectic microstructure of AlCoCrFeNi2.1 are preserved.

The Twin Pillars of Alloy Quality

The preparation of high-entropy alloys (HEAs) requires overcoming two main challenges: oxidation of active metals and segregation of elements with different densities. The vacuum induction furnace addresses these through two distinct mechanisms.

Preventing Oxidative Loss

The primary reference indicates that the furnace operates under a high-vacuum environment. This is essential for AlCoCrFeNi2.1 because elements like Aluminum (Al) and Chromium (Cr) are "active," meaning they react aggressively with oxygen at high temperatures.

If these elements were to oxidize, they would form slag rather than integrating into the alloy matrix. This would shift the chemical composition away from the target ratio, potentially destroying the specific eutectic properties of the material.

Ensuring Homogeneity via Induction Stirring

AlCoCrFeNi2.1 consists of five distinct metallic elements, each with its own density and melting point. Without active intervention, these elements might stratify or mix unevenly.

The furnace generates an induction stirring effect within the liquid phase. This electromagnetic force creates a natural convection current in the crucible, continuously circulating the melt. This ensures that heavy and light elements are thoroughly blended, resulting in ingots with uniform chemical distribution from top to bottom.

The Significance for Eutectic Microstructures

Precision is Non-Negotiable

Unlike standard alloys, a "eutectic" alloy forms a specific lamellar microstructure only at a very precise chemical composition ratio.

The vacuum induction furnace ensures that the final ingot retains the exact "recipe" calculated by the metallurgist. By preventing the loss of volatile or active elements to the atmosphere, the furnace guarantees that the liquid metal solidifies into the intended AlCoCrFeNi2.1 phase structure.

Elimination of Impurity Gases

Beyond preventing solid oxides, the vacuum environment facilitates degassing. It removes dissolved gases that could lead to porosity or brittleness in the final casting, ensuring the mechanical integrity of the alloy.

Operational Considerations and Trade-offs

While the vacuum induction furnace is the superior choice for this application, operators must be aware of specific process dynamics to maximize results.

Managing Vapor Pressure

While a high vacuum prevents oxidation, it can theoretically lead to the evaporation of elements with high vapor pressures if not monitored.

To mitigate this, the process often involves backfilling the chamber with an inert gas like argon (as noted in supplementary contexts regarding VIM processes). This creates a "controlled atmosphere" that suppresses volatilization while still blocking oxygen.

Crucible Compatibility

The induction process generates intense localized heat. It is vital to ensure the crucible material does not react with the high-entropy melt, as this would introduce new impurities that the vacuum cannot remove.

Making the Right Choice for Your Goal

To achieve the best results with AlCoCrFeNi2.1, align your furnace operation with your specific metallurgical objectives.

- If your primary focus is Chemical Precision: Prioritize the vacuum level to ensure zero oxidative loss of Aluminum, which is the most vulnerable element in this matrix.

- If your primary focus is Microstructural Uniformity: Maximize the induction frequency and power to enhance the stirring effect, ensuring the five elements are physically indistinguishable in the liquid phase.

The vacuum induction furnace is not just a heat source; it is a precision tool that locks in the chemistry required for high-performance eutectic alloys.

Summary Table:

| Feature | Role in AlCoCrFeNi2.1 Smelting | Key Benefit |

|---|---|---|

| High Vacuum Environment | Prevents Al and Cr from reacting with oxygen | Maintains precise eutectic chemical ratios |

| Induction Stirring | Electromagnetic circulation of five distinct elements | Ensures physical homogeneity and zero segregation |

| Degassing Capability | Removes dissolved gases from the melt | Eliminates porosity and improves mechanical integrity |

| Atmosphere Control | Inert gas backfilling options | Suppresses element volatilization and vapor loss |

Elevate Your Advanced Metallurgy with KINTEK

Precision in AlCoCrFeNi2.1 production demands equipment that guarantees zero atmospheric contamination and perfect elemental mixing. KINTEK provides state-of-the-art Vacuum, Induction, and CVD systems designed specifically for the rigorous requirements of high-entropy alloy research.

Backed by expert R&D and world-class manufacturing, our lab high-temp furnaces are fully customizable to your unique smelting protocols. Don't settle for inconsistent alloy quality—trust KINTEK to deliver the control you need.

Contact Our Technical Specialists Today to discuss your custom furnace requirements!

Visual Guide

References

- Effect of Heat Treatment on Corrosion of an AlCoCrFeNi2.1 Eutectic High-Entropy Alloy in 3.5 wt% NaCl Solution. DOI: 10.3390/met15060681

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is Joule heating and how does it relate to induction furnaces? Master Efficient Metal Melting

- What are the primary advantages of using vacuum melting furnaces? Achieve Superior Purity and Control for High-Performance Materials

- Why is an argon atmosphere maintained during VIM of Chromium-Silicon alloys? Prevent High Chromium Loss

- How do induction furnaces work in metal casting? Unlock Efficient, High-Quality Melting Solutions

- Why is the melting process for AlCoCrFeNi HEAs repeated 3 times? Achieving Pure Chemical Homogeneity

- How does an induction furnace work? Achieve Clean, Fast, and Controlled Metal Melting

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery