At its core, an induction furnace uses a powerful, fluctuating magnetic field to generate heat directly within the material being melted. Unlike traditional furnaces that rely on external flames or heating elements, induction heating works from the inside out, offering a cleaner, faster, and more controlled melting process. This method avoids combustion, minimizing contamination and allowing for operation in controlled atmospheres.

The fundamental advantage of an induction furnace is not just melting metal, but achieving precise control over temperature, purity, and alloy composition through contactless electromagnetic heating.

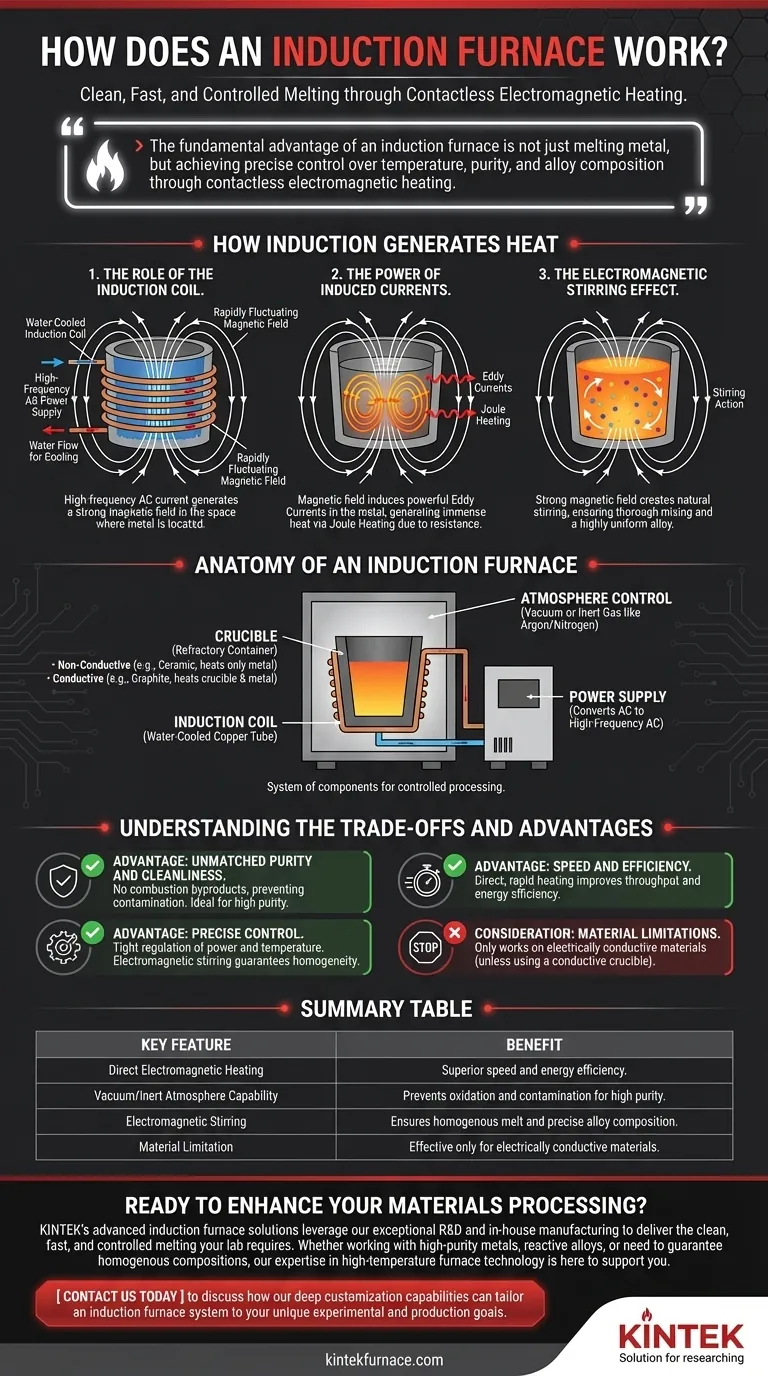

How Induction Generates Heat

Induction heating is a highly efficient, direct heating method. It relies on fundamental principles of electromagnetism to convert electrical energy into thermal energy within the target material.

The Role of the Induction Coil

The process begins with a high-frequency alternating current (AC) passing through a water-cooled copper coil. This coil, which surrounds the crucible containing the metal, does not get hot itself. Its sole purpose is to generate a strong, rapidly changing magnetic field in the space where the metal is located.

The Power of Induced Currents

This fluctuating magnetic field penetrates the electrically conductive metal charge inside the crucible. According to Faraday's law of induction, the changing magnetic field induces powerful electrical currents, known as eddy currents, to flow within the metal.

Due to the metal's natural electrical resistance, the flow of these eddy currents generates immense heat—a phenomenon known as Joule heating. This heat is generated directly inside the material, leading to rapid and uniform melting.

The Electromagnetic Stirring Effect

A secondary benefit of the strong magnetic field is that it creates a natural stirring action within the molten metal. This electromagnetic stirring ensures that different elements are mixed thoroughly, resulting in a highly uniform and homogenous final alloy.

Anatomy of an Induction Furnace

While the principle is elegant, the furnace itself is a system of critical components working in concert to ensure a controlled process.

The Crucible

The crucible is the refractory container that holds the metal. Its material is a critical choice.

- Non-Conductive Crucibles: If the crucible is made of a non-conductive material like a ceramic refractory, the magnetic field passes through it and heats only the metal charge directly. This is ideal for maximizing purity.

- Conductive Crucibles: If a conductive crucible (e.g., graphite) is used, the magnetic field heats both the crucible and the metal charge. This can be useful for certain applications.

The Induction Coil

As mentioned, this is typically a hollow copper tube that surrounds the crucible. Water is continuously circulated through it to dissipate waste heat and prevent the coil itself from melting.

The Power Supply

A specialized power supply unit is required to convert standard utility-frequency AC power into the high-frequency AC power needed to energize the induction coil effectively.

Atmosphere Control

Induction furnaces excel in controlled environments. The crucible and coil assembly can be enclosed in a chamber, allowing the process to occur in a vacuum or under a blanket of inert gas (like Argon or Nitrogen). This prevents oxidation and removes impurities, which is essential for producing high-purity metals and reactive alloys.

Understanding the Trade-offs and Advantages

No technology is a universal solution. Understanding the unique benefits and considerations of induction furnaces is key to using them effectively.

Advantage: Unmatched Purity and Cleanliness

Because heat is generated directly within the metal, there are no byproducts of combustion (like in a gas furnace) to contaminate the melt. This, combined with atmosphere control, makes induction furnaces the standard for applications demanding high purity.

Advantage: Speed and Efficiency

Directly heating the material is significantly faster and more energy-efficient than heating the air and walls of a large chamber first. Furnaces can be brought to temperature very quickly, improving throughput.

Advantage: Precise Control

The power supplied to the coil can be regulated with extreme precision, allowing for tight control over temperature. The inherent stirring effect also guarantees excellent control over the final alloy composition and homogeneity.

Consideration: Material Limitations

Induction heating only works on materials that are electrically conductive. It is not suitable for directly heating non-conductive materials like ceramics, unless a conductive crucible is used to act as an intermediary heating element.

Making the Right Choice for Your Goal

Selecting an induction furnace is about matching its specific capabilities to your material processing needs.

- If your primary focus is high-purity metals or reactive alloys: The ability to melt in a vacuum or inert atmosphere to prevent oxidation is the defining feature you need.

- If your primary focus is creating homogenous, precision alloys: The natural electromagnetic stirring effect is a critical advantage that guarantees a uniform mix without mechanical stirrers.

- If your primary focus is rapid production and energy efficiency: The speed and direct heating nature of induction offer significant advantages over slower, indirect-heating furnace types.

Ultimately, the induction furnace is a precision tool for advanced materials processing, offering a level of control that traditional methods cannot match.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Direct Electromagnetic Heating | Heat is generated within the metal itself for superior speed and energy efficiency. |

| Vacuum/Inert Atmosphere Capability | Prevents oxidation and contamination, ideal for high-purity metals and reactive alloys. |

| Electromagnetic Stirring | Ensures a homogenous melt and precise alloy composition without mechanical parts. |

| Material Limitation | Only effective for heating electrically conductive materials. |

Ready to enhance your materials processing with precision and purity?

KINTEK's advanced induction furnace solutions leverage our exceptional R&D and in-house manufacturing to deliver the clean, fast, and controlled melting your lab requires. Whether you are working with high-purity metals, reactive alloys, or need to guarantee homogenous compositions, our expertise in high-temperature furnace technology is here to support you.

Contact us today to discuss how our deep customization capabilities can tailor an induction furnace system to your unique experimental and production goals.

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control