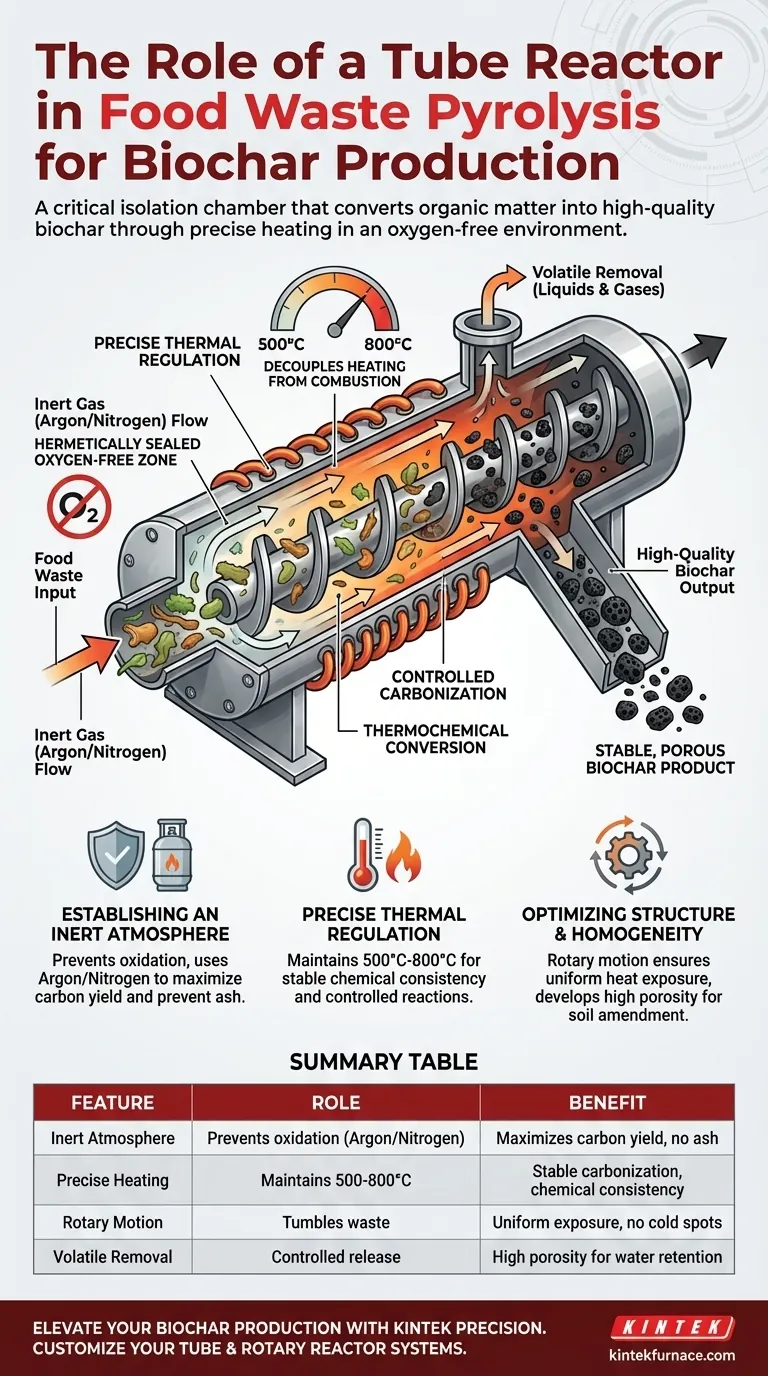

A tube reactor functions as the critical isolation chamber during the pyrolysis of food waste, providing the specific environmental conditions necessary to turn organic matter into biochar rather than ash. Its primary role is to maintain a sealed, oxygen-free zone where precise heating drives thermochemical conversion, ensuring carbon is chemically fixed into a solid state.

Core Takeaway The tube reactor’s value lies in its ability to decouple heating from combustion. By strictly controlling temperature and utilizing an inert gas flow, it forces biomass to undergo carbonization, maximizing carbon sequestration and creating a stable, high-quality biochar product.

The Principles of Controlled Carbonization

The conversion of food waste into biochar requires a departure from standard combustion. The tube reactor creates the specific physical constraints required to achieve this.

Establishing an Inert Atmosphere

The most fundamental role of the tube reactor is preventing oxidation. The vessel is hermetically sealed to exclude ambient air.

To replace the oxygen, the system introduces an inert gas, such as argon (as noted in primary methodologies) or nitrogen. This gas flows continuously through the tube, creating a protective blanket around the food waste.

Without this isolation, the carbon in the food waste would react with oxygen and burn away as carbon dioxide (CO2). The tube reactor ensures the carbon remains trapped in the solid phase, aligning with negative carbon emission goals.

Precise Thermal Regulation

Biochar quality depends on specific temperature profiles. The tube reactor acts as a thermal regulator, maintaining the reaction environment typically between 500°C and 800°C.

This consistent high heat triggers specific chemical changes, such as dehydration and decarbonization. The reactor ensures these reactions happen at a controlled rate, preventing thermal shock or uneven processing that could degrade the final product.

Optimizing Physical Structure and Homogeneity

Beyond simple chemical conversion, the mechanical design of the tube reactor influences the physical quality of the resulting biochar.

Ensuring Uniform Heat Exposure

Food waste is a heterogeneous feedstock, meaning it often has inconsistent density and moisture content.

Many tube reactors utilized for food waste employ a rotary motion. This mechanical rotation tumbles the organic material, ensuring that every particle is exposed to the heat source evenly.

This uniformity is vital for consistent carbonization. It prevents "cold spots" where waste might remain raw and "hot spots" where it might over-cook and become brittle.

Developing Porosity

The specific environment within the tube reactor fosters the development of a high-porosity structure.

By driving off volatile compounds (liquids and gases) in a controlled manner, the reactor leaves behind a rigid carbon skeleton. This porous structure is what makes biochar valuable for soil amendment, as it retains water and nutrients.

Understanding the Trade-offs

While tube reactors offer high precision, they introduce specific operational complexities that must be managed.

Dependency on Inert Gas Supply

The system is entirely reliant on the continuous flow of inert gas (argon or nitrogen). Any interruption in gas flow or a breach in the tube's seal immediately compromises the anaerobic environment. This can lead to partial combustion, significantly reducing biochar yield and quality.

Energy and Throughput Limitations

Maintaining high temperatures (up to 800°C) generally requires substantial energy input via external heating elements. Furthermore, while rotary tube reactors improve uniformity, they may have lower throughput capacities compared to large-scale industrial incinerators, making them better suited for high-quality, targeted biochar production rather than mass waste volume reduction.

Making the Right Choice for Your Goal

The configuration of your tube reactor should depend on the specific characteristics you require in your final biochar product.

- If your primary focus is Carbon Sequestration: Prioritize a reactor with a high-integrity seal and Argon flow to maximize the fixation of carbon and minimize CO2 release.

- If your primary focus is Soil Amendment (Agriculture): Focus on a rotary tube furnace design to ensure uniform heating, which optimizes the porous structure required for water retention.

- If your primary focus is Material Activation: Operate the reactor at higher temperature ranges (near 800°C) to facilitate the advanced dehydration and skeletal formation necessary for later activation steps.

Success in biochar production is less about how hot you can get the waste, and more about how strictly you can control the environment around it.

Summary Table:

| Feature | Role in Food Waste Pyrolysis | Benefit to Biochar Quality |

|---|---|---|

| Inert Atmosphere | Prevents oxidation by using Argon/Nitrogen | Maximizes carbon yield and prevents ash formation |

| Precise Heating | Maintains 500°C - 800°C profiles | Ensures stable carbonization and chemical consistency |

| Rotary Motion | Tumbles heterogeneous food waste | Provides uniform heat exposure and prevents cold spots |

| Volatile Removal | Controlled release of liquids/gases | Develops high porosity for water and nutrient retention |

Elevate Your Biochar Production with KINTEK Precision

Unlock the full potential of your carbonization research with KINTEK’s high-performance tube and rotary reactor systems. Backed by expert R&D and manufacturing, we provide the precise thermal control and airtight environments essential for transforming food waste into high-value biochar. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temp furnaces are fully customizable to meet your unique processing needs.

Ready to optimize your pyrolysis yield? Contact us today to discuss your custom solution and see how our expertise can drive your sustainability goals forward.

Visual Guide

References

- Zsolt Dobó, Gábor Nagy. Production of Biochar by Pyrolysis of Food Waste Blends for Negative Carbon Dioxide Emission. DOI: 10.3390/en18010144

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a three-tube diffusion furnace ensure the quality of thermal oxidation layers? Achieve High-Efficiency Passivation

- What role does a horizontal tube furnace play in chromite reduction? Master Precision Solid-State Processing

- How does a tube furnace differ from HPHT methods for Fe2B-HS? Compare Diffusion and Structural Integrity

- What temperature is maintained by the water cooling system in Quartz Tube Furnaces? Ensure Seal Integrity at 20°C

- How is a tube furnace utilized to construct DTB sites for Co/Co0.85Se@NC? Mastering Phase Engineering

- What environmental conditions does a high-temperature Tube furnace provide for AlN nanofibers? | KINTEK

- What is the purpose of a high-purity argon protection system in a tube furnace? Safeguard MoS2/C Material Integrity

- Why is pre-oxidation treatment of the substrate in a tube furnace necessary? Ensure Strong Ti(Nb)-Si-C Coating Adhesion