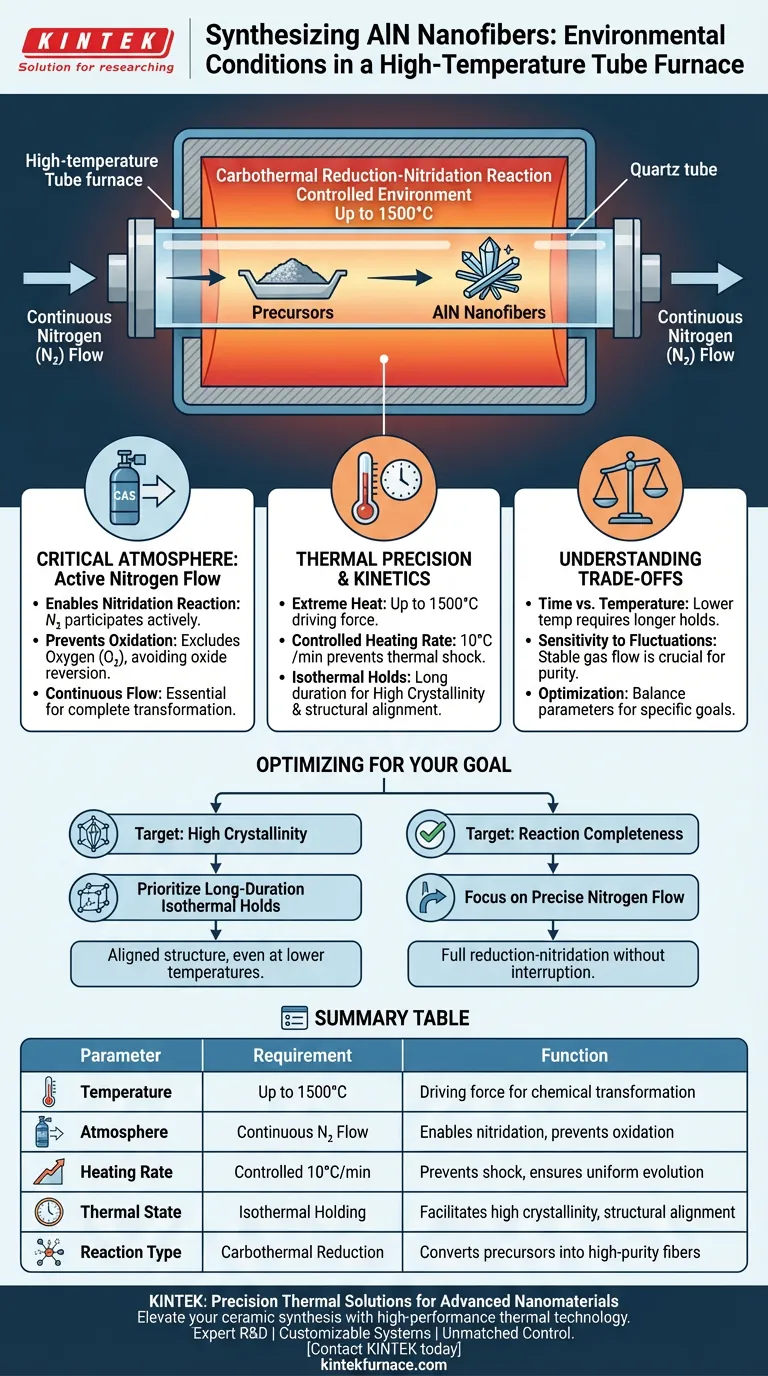

A high-temperature tube furnace provides a rigorously controlled environment defined by extreme heat (up to 1500°C) and a continuous, active flow of nitrogen gas. This specific setup is required to manage precise heating kinetics, such as a rate of 10°C per minute, which is essential for converting precursors into Aluminum Nitride (AlN) nanofibers.

The tube furnace functions as a precise chemical reactor that enables the carbothermal reduction-nitridation reaction. By maintaining a strictly controlled nitrogen atmosphere and allowing for long-duration isothermal holds, it ensures the complete transformation of precursors into high-crystallinity AlN nanofibers, even at temperatures lower than theoretically required.

The Critical Role of Atmosphere

Enabling the Nitridation Reaction

The most distinct feature of the tube furnace in this process is its ability to maintain a continuous nitrogen gas flow.

Unlike standard heating, this process requires nitrogen not just as a protective shield, but as an active participant in the reaction.

This flow ensures that the carbothermal reduction-nitridation reaction proceeds to completion, effectively transforming the starting materials into the desired nitride phase.

Preventing Oxidation

The sealed nature of the tube furnace creates an isolated environment that excludes oxygen.

This is vital because the presence of oxygen during the high-temperature phase would likely revert the precursors to oxides rather than the target Aluminum Nitride nanofibers.

Thermal Precision and Kinetics

Achieving High-Temperature Thresholds

The furnace must be capable of reaching and sustaining temperatures up to 1500°C.

This high thermal energy provides the necessary driving force for the chemical changes required to synthesize ceramic nanofibers.

Controlling Heating Rates

Success in this process relies on specific heating kinetics, such as a controlled ramp rate of 10°C per minute.

Regulating the speed of temperature increase prevents thermal shock and ensures that the chemical evolution of the nanofibers occurs uniformly.

Isothermal Heat Treatments

The tube furnace facilitates long-duration isothermal heat treatments, where the temperature is held constant for an extended period.

This "holding time" is essential for the internal structural arrangement of the material, ensuring the final nanofibers possess high crystallinity.

Understanding the Trade-offs

Time vs. Temperature

A major advantage of this specific setup is the ability to synthesize materials below their theoretical formation thresholds.

However, the trade-off is time. To achieve conversion at these "lower" temperatures, you must commit to longer isothermal holding periods to ensure the reaction finishes completely.

Sensitivity to Atmosphere Fluctuations

The process is highly sensitive to the stability of the gas flow.

Because the nitrogen flow is integral to the chemical reaction, any interruption or fluctuation in the gas supply can compromise the purity of the AlN nanofibers, leading to incomplete reduction or nitridation.

Making the Right Choice for Your Goal

To maximize the quality of your Aluminum Nitride nanofibers, prioritize your process parameters based on your specific outcome:

- If your primary focus is High Crystallinity: Prioritize long-duration isothermal holds, as this allows the internal structure of the nanofibers to align perfectly even if you are operating below maximum theoretical temperatures.

- If your primary focus is Reaction Completeness: Focus on the precision of the nitrogen flow, ensuring it is continuous and sufficient to drive the full carbothermal reduction-nitridation reaction without interruption.

Ultimately, the tube furnace is the definitive tool for this application because it couples extreme thermal capability with the precise atmospheric control required to chemically engineer the nanofiber structure.

Summary Table:

| Process Parameter | Environmental Requirement | Function in AlN Synthesis |

|---|---|---|

| Temperature | Up to 1500°C | Provides driving force for chemical transformation |

| Atmosphere | Continuous Nitrogen ($N_2$) Flow | Enables nitridation and prevents oxidation |

| Heating Rate | Controlled 10°C/min | Prevents thermal shock; ensures uniform evolution |

| Thermal State | Isothermal Holding | Facilitates high crystallinity and structural alignment |

| Reaction Type | Carbothermal Reduction | Converts precursors into high-purity ceramic fibers |

Precision Thermal Solutions for Advanced Nanomaterials

Elevate your ceramic synthesis with KINTEK’s high-performance thermal technology. Whether you are performing complex carbothermal reduction or sensitive nitridation, our high-temperature tube furnaces deliver the rigorous atmospheric control and thermal precision required for high-crystallinity AlN nanofibers.

Why Choose KINTEK?

- Expert R&D & Manufacturing: Built for durability and extreme precision up to 1500°C.

- Customizable Systems: We offer Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab specifications.

- Unmatched Control: Secure the stable gas flow and heating kinetics essential for your research success.

Ready to optimize your calcination process? Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Md. Shakhawat Hossain, Koji Nakane. Enhancing heat dissipation in polyurethane sheets through the incorporation of freeze‐dried aluminum nitride nanofiber. DOI: 10.1111/ijac.14725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum pump used to treat the tube reactor before CVD of g-C3N4? Ensure High-Purity Thin Film Growth

- In which fields and for what processes are vertical tube furnaces widely used? Unlock Precision Material Processing

- Why is a high-temperature tube furnace required for LK-99 sintering? Achieve Precise Superconductor Phase Transformation

- What are the common applications of a vacuum tube furnace? Unlock High-Purity Thermal Processing for Your Lab

- What is the function of a cylindrical furnace during the pre-carbonization of Hanji? Expert Thermal Processing Tips

- What materials are commonly used for reaction tubes in tube furnaces? Choose the Right Tube for Your Lab

- What design features make horizontal furnaces versatile? Achieve High-Volume, Uniform Thermal Processing

- What are the heating zone options for Tube Furnaces? Choose Single or Multi-Zone for Optimal Thermal Control