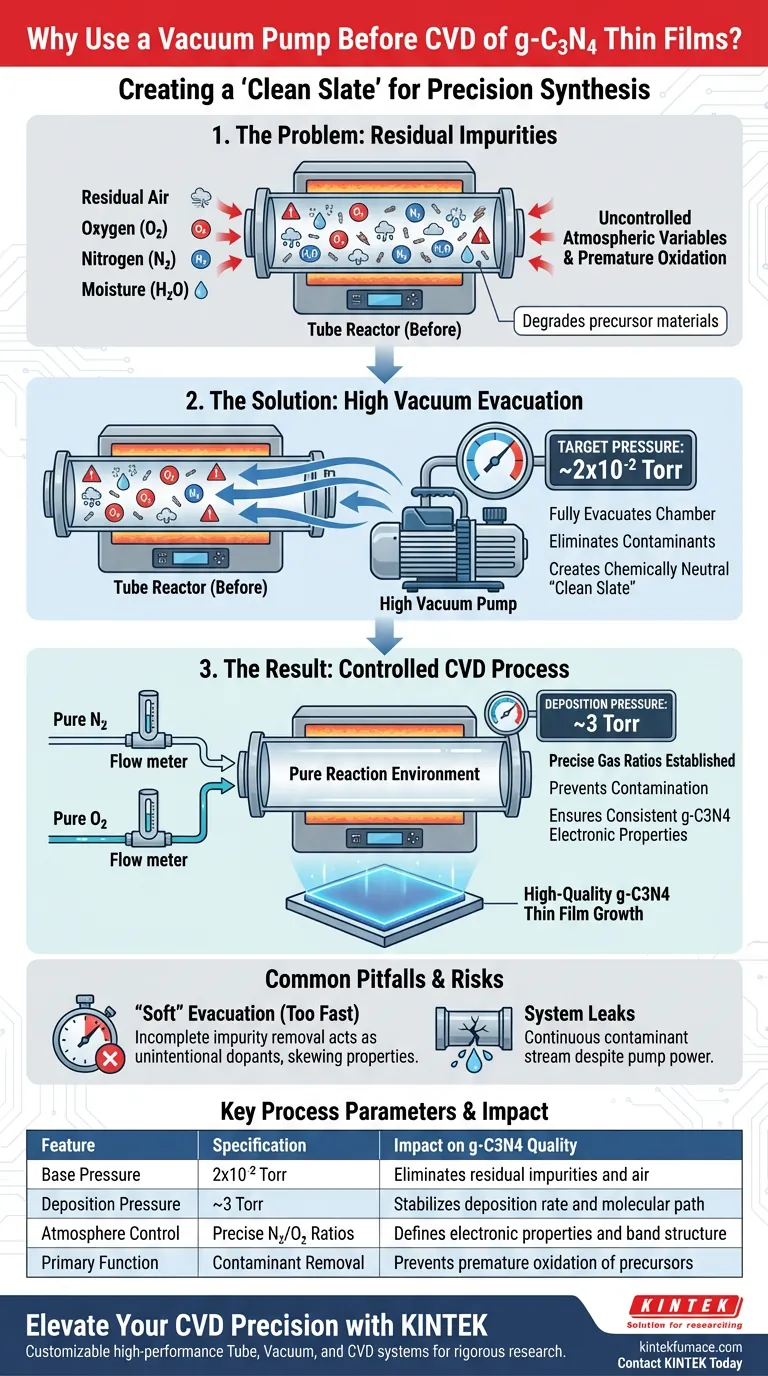

The critical function of the vacuum pump is to fully evacuate the tube reactor, removing residual air and impurity gases before the deposition process begins. By reducing the chamber pressure to approximately 2x10^-2 Torr, the system eliminates uncontrolled atmospheric variables. This ensures that the subsequently introduced gas mixture (typically Nitrogen and Oxygen) maintains a precise ratio, preventing contamination that would otherwise alter the chemical composition and electronic properties of the graphitic carbon nitride (g-C3N4) thin films.

A vacuum pump creates a "clean slate" environment by removing unpredictable atmospheric gases. This baseline is non-negotiable for achieving the exact gas ratios required to synthesize high-quality films with consistent electronic behaviors.

Establishing a Pure Reaction Environment

Eliminating Residual Impurities

The primary role of the vacuum system is to purge the furnace tube of all background gases. Without this step, the chamber contains random concentrations of nitrogen, oxygen, and moisture found in ambient air.

The high vacuum pump reduces the internal pressure to a target of roughly 2x10^-2 Torr. This thorough evacuation ensures that the starting environment is chemically neutral.

Preventing Premature Reactions

If residual air remains in the chamber, the oxygen present can react with precursors unpredictably.

This "premature oxidation" degrades the precursor materials before the actual Chemical Vapor Deposition (CVD) process begins. Evacuation prevents these uncontrolled side reactions, ensuring the precursor contributes only to the desired film growth.

Critical Control of Gas Ratios

Setting the Baseline for Process Gases

For g-C3N4 thin films, the synthesis often requires a specific mixed atmosphere, such as a precise ratio of Nitrogen (N2) to Oxygen (O2).

You cannot establish this precise ratio if the reactor is already filled with air of unknown composition. The vacuum pump clears the stage, allowing operators to introduce the process gases into a void, guaranteeing the mixture is exact.

Regulating Deposition Pressure

Once the chamber is evacuated, the system is then regulated to a controlled deposition pressure (often around 3 Torr).

The vacuum step provides the physical baseline required to reach this state. By starting from a high vacuum and backfilling to 3 Torr with pure process gases, the mean free path of molecules is controlled, stabilizing the deposition rate.

Common Pitfalls and Trade-offs

The Risk of "soft" Evacuation

A common mistake is failing to reach the sufficient base pressure (2x10^-2 Torr) before starting gas flow to save time.

If evacuation is incomplete, trace impurities remain. These impurities act as unintentional dopants, which can drastically skew the electronic properties of the final thin film, leading to poor device performance.

System Integrity vs. Pump Power

A powerful pump cannot compensate for a leaking tube reactor.

Relying solely on the pump speed without verifying the seal integrity can lead to a dynamic equilibrium where air leaks in as fast as it is pumped out. This introduces a continuous stream of contaminants despite the pressure reading appearing low.

Making the Right Choice for Your Goal

To ensure high-quality g-C3N4 thin film deposition, consider the following operational priorities:

- If your primary focus is Chemical Purity: Ensure the vacuum system achieves a stable base pressure of at least 2x10^-2 Torr to fully eliminate residual air before heating.

- If your primary focus is Electronic Consistency: strictly control the backfilling process after evacuation to maintain the exact N2/O2 ratio, as this dictates the film's band structure.

Mastering the initial vacuum stage is the single most effective way to guarantee reproducibility in CVD thin film synthesis.

Summary Table:

| Process Feature | Specification/Requirement | Impact on g-C3N4 Quality |

|---|---|---|

| Target Base Pressure | 2x10^-2 Torr | Eliminates residual impurities and air |

| Deposition Pressure | ~3 Torr | Stabilizes deposition rate and molecular path |

| Atmosphere Control | Precise N2/O2 Ratios | Defines electronic properties and band structure |

| Primary Function | Contaminant Removal | Prevents premature oxidation of precursors |

Elevate Your CVD Precision with KINTEK

Don't let residual impurities compromise your thin film synthesis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of g-C3N4 research. Whether you need precise pressure regulation or advanced thermal control, our lab high-temp furnaces provide the reliable environment your materials deserve.

Ready to optimize your deposition process? Contact KINTEK Today to Consult Our Experts

Visual Guide

References

- Kota Higuchi, Yoshio Hashimoto. Layered carbon nitride films deposited under an oxygen-containing atmosphere and their electronic properties. DOI: 10.1063/5.0193419

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- Why are three-zone tube furnaces in high demand? Unlock Precision for Advanced Materials

- What role does a high-temperature tube furnace play in the final thermal treatment of Na3(VO1-x)2(PO4)2F1+2x?

- What role does a high-temperature tube furnace play in the post-processing of high-entropy alloys? Optimize Microstructure

- What are the drawbacks of corundum tube furnaces? Manage Costs, Visibility, and Thermal Risks

- What is the core function of an industrial programmable tube furnace? Master Titania-Carbon Synthesis with Precision

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- What are the technical advantages of using SPS vs. tube furnaces for SiC? Achieve Superior SiC Properties