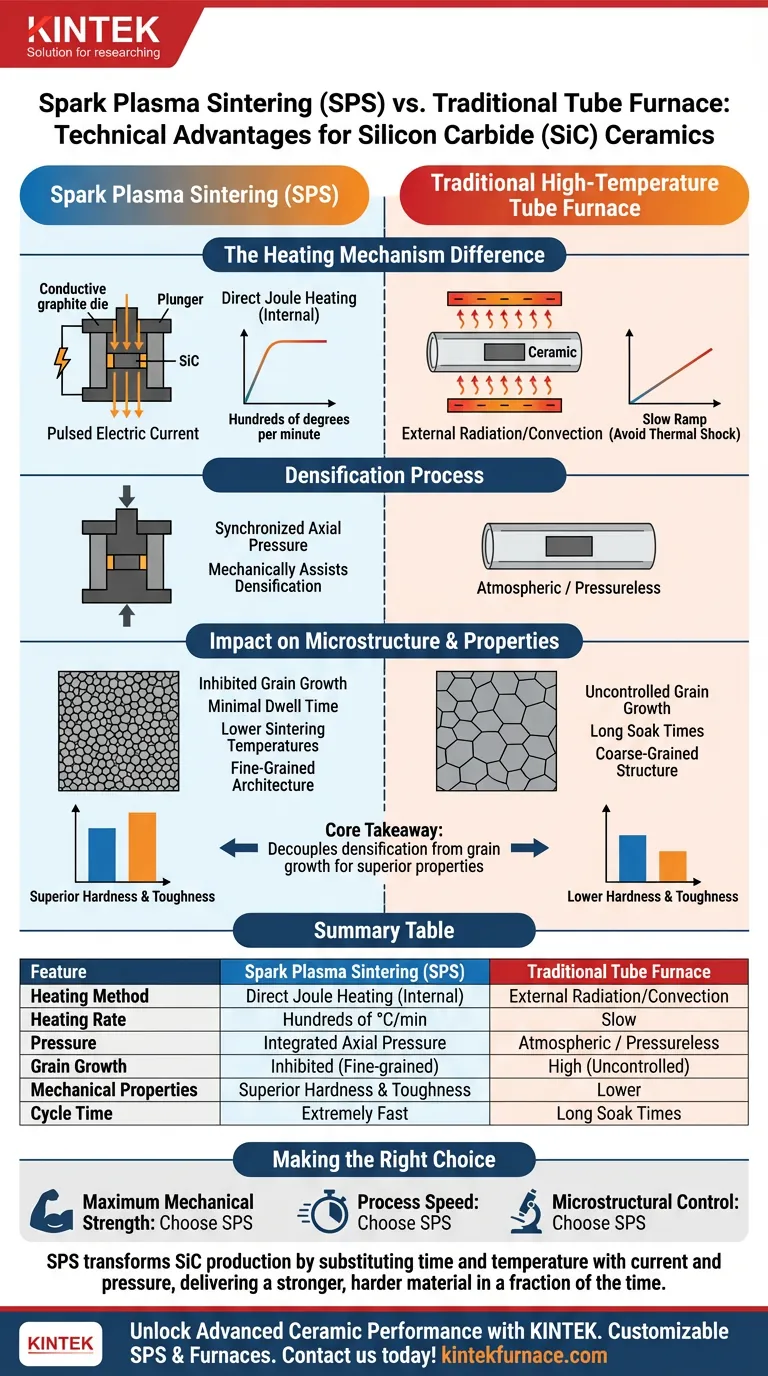

Spark Plasma Sintering (SPS) fundamentally alters the densification process compared to traditional methods by changing how heat is generated. While a standard high-temperature tube furnace relies on external heating elements to heat samples via radiation and convection, an SPS system drives pulsed electric current directly through the mold and the Silicon Carbide (SiC) sample itself. This direct heating mechanism, combined with simultaneous pressure, enables extremely rapid heating rates—often hundreds of degrees per minute—allowing for full densification at lower temperatures and in significantly less time.

Core Takeaway

The definitive advantage of SPS for Silicon Carbide is the ability to decouple densification from grain growth. By achieving high density rapidly at lower temperatures, SPS preserves a fine-grained microstructure, directly resulting in ceramics with superior hardness and fracture toughness that traditional furnaces cannot easily replicate.

The Heating Mechanism Difference

Direct Joule Heating vs. External Radiation

In a traditional tube furnace, heat must travel from the outer elements, through the tube, and finally into the sample. SPS eliminates this thermal lag. By passing pulsed current directly through the mold and the SiC sample, the system generates Joule heat internally.

Extreme Heating Rates

The internal heating mechanism allows SPS systems to achieve heating rates of several hundred degrees per minute. This is a dramatic increase over the slow ramp-up times required by tube furnaces to avoid thermal shock or uneven heating.

Synchronized Pressure

Unlike a standard tube furnace which typically operates at atmospheric pressure, SPS utilizes a pressure mechanism. The system applies axial force to the mold during the heating phase, which mechanically assists in the densification of the SiC powder.

Impact on Microstructure

Inhibiting Grain Growth

One of the critical challenges in processing SiC is that high temperatures usually trigger uncontrolled grain growth, which weakens the material. Because SPS heats the material so quickly, the SiC spends minimal dwell time at the peak temperatures where coarsening occurs.

Lower Sintering Temperatures

The combination of direct pulsed current and mechanical pressure allows SiC to densify at temperatures lower than those required in conventional pressureless sintering. This lower thermal budget further protects the microstructure from degrading.

Fine-Grained Architecture

The result of rapid firing and reduced dwell time is a final product with a fine-grained structure. The grains simply do not have the time or thermal energy to merge and grow large, as they would during the long soak times of a tube furnace cycle.

Resulting Material Properties

Enhanced Fracture Toughness

The microstructural benefits of SPS translate directly to mechanical performance. The fine-grained structure creates a more tortuous path for crack propagation, significantly increasing the fracture toughness of the ceramic.

Superior Hardness

Because the material achieves high relative density without the compromise of large, coarse grains, the final SiC product exhibits superior hardness compared to samples prepared in traditional heating environments.

Understanding the Trade-offs

Complexity of Setup

While a tube furnace is a relatively passive instrument, SPS is a complex dynamic system. It requires the management of high-current pulses and mechanical pressure simultaneously, necessitating precise synchronization that simple thermal cycling does not.

Mold Dependence

The references highlight that current flows through the "mold and sample." Unlike a tube furnace where samples can often be placed freely in boats or crucibles, SPS requires a conductive die setup (typically graphite) to facilitate the heating and pressure application, which can impose geometric constraints on the final part.

Making the Right Choice for Your Goal

If you are deciding between these two technologies for your specific application, consider these factors:

- If your primary focus is Maximum Mechanical Strength: Choose SPS. The ability to inhibit grain growth while maximizing density yields the highest hardness and toughness.

- If your primary focus is Process Speed: Choose SPS. The heating rates of hundreds of degrees per minute significantly reduce overall cycle times compared to traditional firing.

- If your primary focus is Microstructural Control: Choose SPS. It allows you to bypass the intermediate temperature zones where unwanted grain coarsening typically ruins the ceramic's internal structure.

Summary: SPS transforms the production of Silicon Carbide by substituting time and temperature with current and pressure, delivering a stronger, harder material in a fraction of the time.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Tube Furnace |

|---|---|---|

| Heating Method | Direct Joule Heating (Internal) | External Radiation/Convection |

| Heating Rate | Hundreds of degrees per minute | Slow (to avoid thermal shock) |

| Pressure | Integrated axial pressure | Atmospheric / Pressureless |

| Grain Growth | Inhibited (fine-grained) | High (uncontrolled coarsening) |

| Mechanical Properties | Superior Hardness & Toughness | Lower (due to grain growth) |

| Cycle Time | Extremely Fast | Long soak times required |

Unlock Advanced Ceramic Performance with KINTEK

Maximize the potential of your materials with our state-of-the-art sintering solutions. Backed by expert R&D and manufacturing, KINTEK offers high-precision Spark Plasma Sintering (SPS) systems, Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory or industrial needs. Whether you are aiming for maximum mechanical strength or precise microstructural control in Silicon Carbide, our technical team is ready to help you choose the ideal high-temp furnace to elevate your research.

Ready to transform your material processing? Contact us today to find your perfect solution!

Visual Guide

References

- Peroxymonosulfate Activation by Sludge-Derived Biochar via One-Step Pyrolysis: Pollutant Degradation Performance and Mechanism. DOI: 10.3390/w17172588

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the positioning of a quartz tube in a vertical tube furnace contribute to the stability of the synthesis reaction?

- What role do rotary tube furnaces play in the building materials industry? Essential for High-Temperature Material Processing

- What role does a laboratory tube furnace play in the carbonization process of porous carbon particles? Expert Insights

- What are the typical working temperature ranges for lab tube furnaces? Find the Right Furnace for Your Process

- What are the benefits of high yield and product concentration in a tube furnace? Boost Efficiency and Purity in Chemical Processes

- In what scenarios are laboratory high-temperature tube furnaces or muffle furnaces utilized? Study MgTiO3-CaTiO3 Ceramics

- What role does a tubular furnace play in walnut shell carbonization? Master the Art of Stable Carbon Skeleton Creation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents