Laboratory high-temperature tube and muffle furnaces are deployed primarily to establish a baseline for conventional sintering in the study of MgTiO3-CaTiO3 ceramics. These units provide a controlled environment utilizing static thermal radiation over extended periods, allowing researchers to study standard atomic diffusion and compare results against advanced manufacturing methods.

Core Takeaway While modern techniques like Spark Plasma Sintering (SPS) offer rapid processing, conventional furnaces remain essential for creating a "control" standard. They facilitate the analysis of crystal structure, phase composition, and dielectric properties under traditional thermodynamic conditions, serving as the benchmark for validating the effectiveness of newer heat treatment paths.

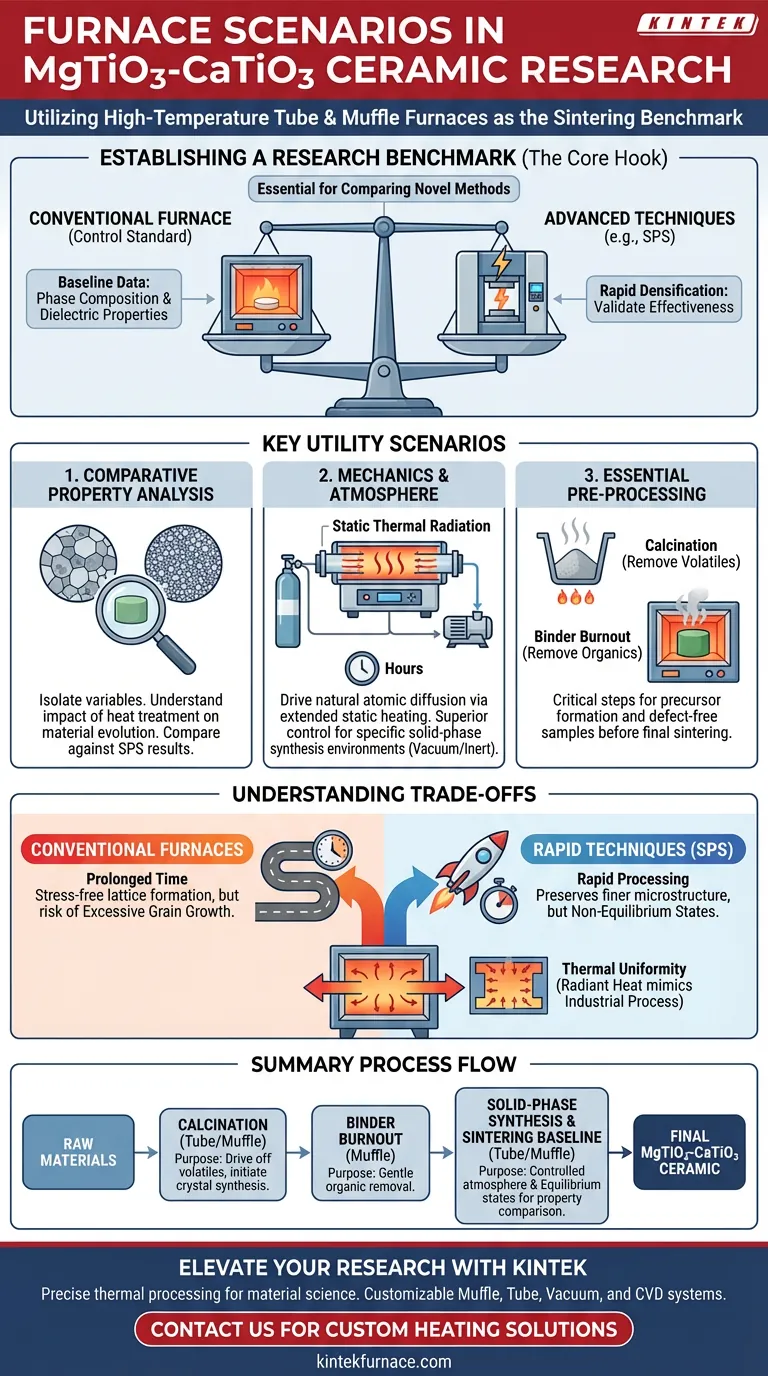

Establishing a Research Benchmark

Comparison with Advanced Techniques

In the research of MgTiO3-CaTiO3 ceramics, the primary utility of these furnaces is to act as a comparative benchmark.

Researchers often employ advanced methods like Spark Plasma Sintering (SPS) to achieve rapid densification. However, to understand the true impact of these rapid techniques, they must compare the resulting material properties against those achieved through conventional heating.

Analyzing Property Evolution

By using standard tube or muffle furnaces, scientists can isolate specific variables in the heating process.

This allows for a precise analysis of how different heat treatment paths influence phase composition and the evolution of dielectric properties. Without this baseline, it is difficult to determine if property improvements are due to the material composition or the sintering speed.

The Mechanics of Conventional Sintering

Driving Atomic Diffusion

Unlike rapid techniques that may use pressure or pulsed current, conventional furnaces rely on static thermal radiation.

This process typically spans several hours. The extended duration is necessary to drive atomic diffusion naturally, ensuring the material reaches a state of equilibrium that differs from the non-equilibrium states often produced by rapid sintering.

Controlled Atmospheric Synthesis

Tube furnaces, in particular, are utilized when specific atmospheric conditions are required during the solid-phase synthesis of MgTiO3-CaTiO3.

These units offer superior management of the environment, including vacuum or inert gas protection. This ensures that chemical reactions occur under precise thermodynamic conditions, preventing oxidation or unwanted side reactions that could alter the physicochemical properties of the ceramic.

Essential Pre-processing Scenarios

Calcination and Solid-Phase Synthesis

Before final sintering, raw materials often require calcination.

High-temperature furnaces are used to heat the initial powders to drive off volatile components and initiate the formation of the desired crystal phases. This step is critical for synthesizing the precursor powders that will later be pressed and sintered.

Binder Burnout

In the preparation of ceramic samples, organic binders are often added to help shape the "green" (unfired) body.

Muffle furnaces are extensively used for binder burnout. This process involves heating the sample at lower temperatures to gently remove organic matter before the high-temperature sintering phase begins, ensuring the final ceramic is free of carbon defects.

Understanding the Trade-offs

Processing Time vs. Microstructure

The primary trade-off when using conventional furnaces is time. The process requires hours of heating, holding, and cooling.

While this allows for stress-free lattice formation, the prolonged exposure to high heat can lead to excessive grain growth. In contrast, rapid techniques like SPS often preserve finer grain structures. Therefore, these furnaces are less suitable for research specifically aiming to produce nanostructured ceramics, but remain the standard for bulk ceramic studies.

Thermal Uniformity

While muffle furnaces generally use baffles to distribute heat, they rely on radiant transfer.

This can sometimes create slight thermal gradients compared to the direct heating of SPS. However, for most conventional sintering research, this mimics the standard industrial manufacturing process, making the data highly relevant for mass-production scalability.

Making the Right Choice for Your Goal

To maximize the value of your research into MgTiO3-CaTiO3 ceramics, align your equipment choice with your specific analytical needs:

- If your primary focus is establishing a baseline: Use a tube or muffle furnace to generate standard data on phase composition and dielectric properties driven by natural atomic diffusion.

- If your primary focus is material synthesis and preparation: Utilize these furnaces for critical pre-processing steps like calcination and binder burnout to ensure sample purity.

- If your primary focus is comparing novel techniques: Use the conventional sintered samples as the "control group" to rigorously validate the benefits of rapid methods like SPS.

By using high-temperature furnaces as a rigorous standard, you ensure your advanced research is grounded in fundamental material science principles.

Summary Table:

| Process Scenario | Equipment Used | Primary Purpose |

|---|---|---|

| Sintering Baseline | Muffle/Tube Furnace | Establish a control standard for dielectric property comparison. |

| Solid-Phase Synthesis | Tube Furnace | Controlled atmosphere (vacuum/inert) for pure phase formation. |

| Calcination | Muffle/Tube Furnace | Driving off volatiles and initiating crystal phase synthesis. |

| Binder Burnout | Muffle Furnace | Gentle removal of organic matter before high-temp sintering. |

| Atomic Diffusion | Muffle Furnace | Analyzing equilibrium states via static thermal radiation. |

Elevate Your Ceramic Research with KINTEK

Precise thermal processing is the backbone of material science. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of MgTiO3-CaTiO3 synthesis and sintering.

Whether you need to establish a research benchmark or scale your production, our lab high-temperature furnaces deliver the thermal uniformity and atmospheric control your project requires. Contact us today to find your custom heating solution!

Visual Guide

References

- Wega Trisunaryanti, Satriyo Dibyo Sumbogo. Characteristic and Performance of Ni, Pt, and Pd Monometal and Ni-Pd Bimetal onto KOH Activated Carbon for Hydrotreatment of Castor Oil. DOI: 10.22146/ijc.84640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does a programmable tube furnace facilitate Al/SiC material transformation? Precision Heat for Ceramic Coatings

- What are the specialized functions of a high-temperature tube furnace in the final sintering of proton ceramics?

- How does the environmental control within a high-temperature tube furnace affect Ag-N-C catalyst pyrolysis?

- How is a Pulse Ignition device used for coal cloud explosions? Master MAIT Testing with Godbert-Greenwald Furnaces

- What materials are used for a tube furnace heating chamber? Optimize for temperature, purity, and durability.

- What are the advantages of using a laboratory tube furnace for BCZT ceramics? Boost Piezoelectric d33 by up to 41%

- What role does a high-temperature tube furnace play in graphite recycling? Restoring Purity and Structure

- What is the function of an industrial-grade tube furnace? Mastering Expanded Graphite (EG) Calcination