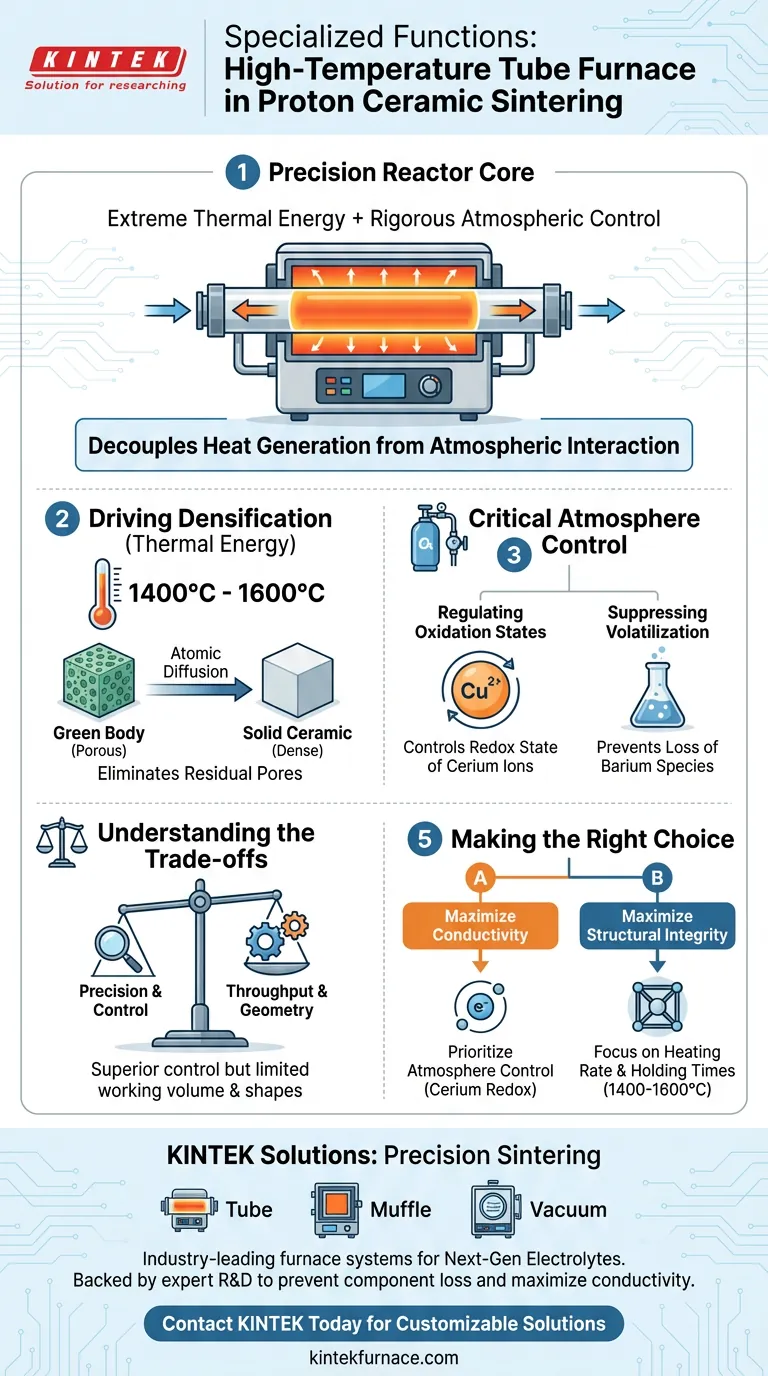

The high-temperature tube furnace acts as a precision reactor designed to sinter proton ceramic electrolytes by combining extreme thermal energy with rigorous atmospheric control. It functions primarily to drive densification at temperatures between 1400 °C and 1600 °C while utilizing a sealed environment to regulate oxygen flow. This specialized control is essential for managing the chemical stability of sensitive elements like cerium and barium, ensuring the final membrane is both dense and conductive.

The core value of the tube furnace lies in its ability to decouple heat generation from atmospheric interaction. By isolating the sample, it allows you to drive atomic diffusion for densification without suffering the chemical degradation or component loss typical of open-air firing.

Driving Densification Through Thermal Energy

Achieving Essential Temperatures

Proton ceramic electrolytes require a significant thermal drive to transition from a green body to a solid ceramic. The tube furnace provides the capability to reach and sustain the necessary 1400 °C to 1600 °C range.

Eliminating Residual Pores

At these high temperatures, the furnace creates a stable thermal field that promotes atomic diffusion across grain boundaries. This process effectively eliminates residual pores, transforming the porous green body into a highly dense structure required for efficient ion transmission.

The Critical Role of Atmosphere Control

Regulating Oxidation States

The sealed nature of the tube allows for precise manipulation of the sintering atmosphere, such as maintaining specific oxygen flow rates. This is vital for controlling the redox state of cerium ions, ensuring the material maintains the correct electronic properties.

Suppressing Volatilization

One of the most specialized functions of this apparatus is the suppression of volatile components. By controlling the internal pressure and gas composition, the furnace prevents the volatilization of barium species, which are prone to evaporation at sintering temperatures.

Understanding the Trade-offs

Precision vs. Throughput

While the tube furnace offers superior control over atmosphere and temperature homogeneity, it generally has a smaller working volume compared to box furnaces.

Geometric Constraints

The tubular design limits the size and shape of the ceramic electrolytes you can sinter. It is highly effective for smaller batches or specific geometries but may not be suitable for large-scale production of irregularly shaped components.

Making the Right Choice for Your Goal

To maximize the effectiveness of your sintering process, align your furnace settings with your specific material challenges:

- If your primary focus is maximizing conductivity: Prioritize the atmosphere control settings to strictly regulate the redox state of cerium ions.

- If your primary focus is structural integrity: Focus on the heating rate and holding times at the peak temperature (1400–1600 °C) to ensure full densification without warping.

Success in sintering proton ceramics relies on balancing high thermal energy with the delicate preservation of chemical stoichiometry.

Summary Table:

| Feature | Specialized Function in Sintering | Benefit to Electrolyte |

|---|---|---|

| Thermal Range | Operates at 1400°C to 1600°C | Achieves full densification and eliminates residual pores |

| Atmosphere Control | Sealed environment with regulated gas flow | Maintains redox state of cerium and prevents chemical degradation |

| Volatilization Suppression | Internal pressure and composition control | Prevents the loss of sensitive barium species at high heat |

| Thermal Field Stability | Uniform heat distribution | Ensures structural integrity and consistent ionic conductivity |

Precision Sintering for Next-Gen Electrolytes

Achieving the perfect balance of densification and chemical stability in proton ceramics requires equipment that offers more than just heat. KINTEK provides industry-leading Tube, Muffle, and Vacuum furnace systems backed by expert R&D to meet the rigorous demands of your lab. Whether you need precise atmosphere regulation or customizable high-temperature zones, our solutions are designed to prevent component loss and maximize material conductivity.

Ready to elevate your material research? Contact KINTEK today to discover our customizable high-temperature furnace solutions.

Visual Guide

References

- Zehua Wang, Zongping Shao. New Understanding and Improvement in Sintering Behavior of Cerium‐Rich Perovskite‐Type Protonic Electrolytes. DOI: 10.1002/adfm.202402716

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the significance of using perforated tapered silicone stoppers to seal quartz tube reactors? Achieve Precision.

- What safety features are included in a High Temperature Tube Furnace? Ensure Safe Operation in Extreme Heat

- Why is it critical to precisely control the heating rate at 3°C/min for Ni/NiO@GF electrodes? Achieve Structural Integrity

- How do temperature control and uniformity differ between vertical and horizontal tube furnaces? Optimize Your Lab's Heat Processing

- How does a vertical tube furnace comply with environmental standards? Achieve Eco-Friendly and Efficient Lab Operations

- What role does a high-temperature tube furnace play in biomass carbon skeletons? Master Structural Integrity.

- What are the roles of a vacuum tube furnace and a CCD camera in high-temperature wettability testing? Key Insights

- What is the mechanism by which the presulfidation process influences the coking behavior of cracking furnace tubes?