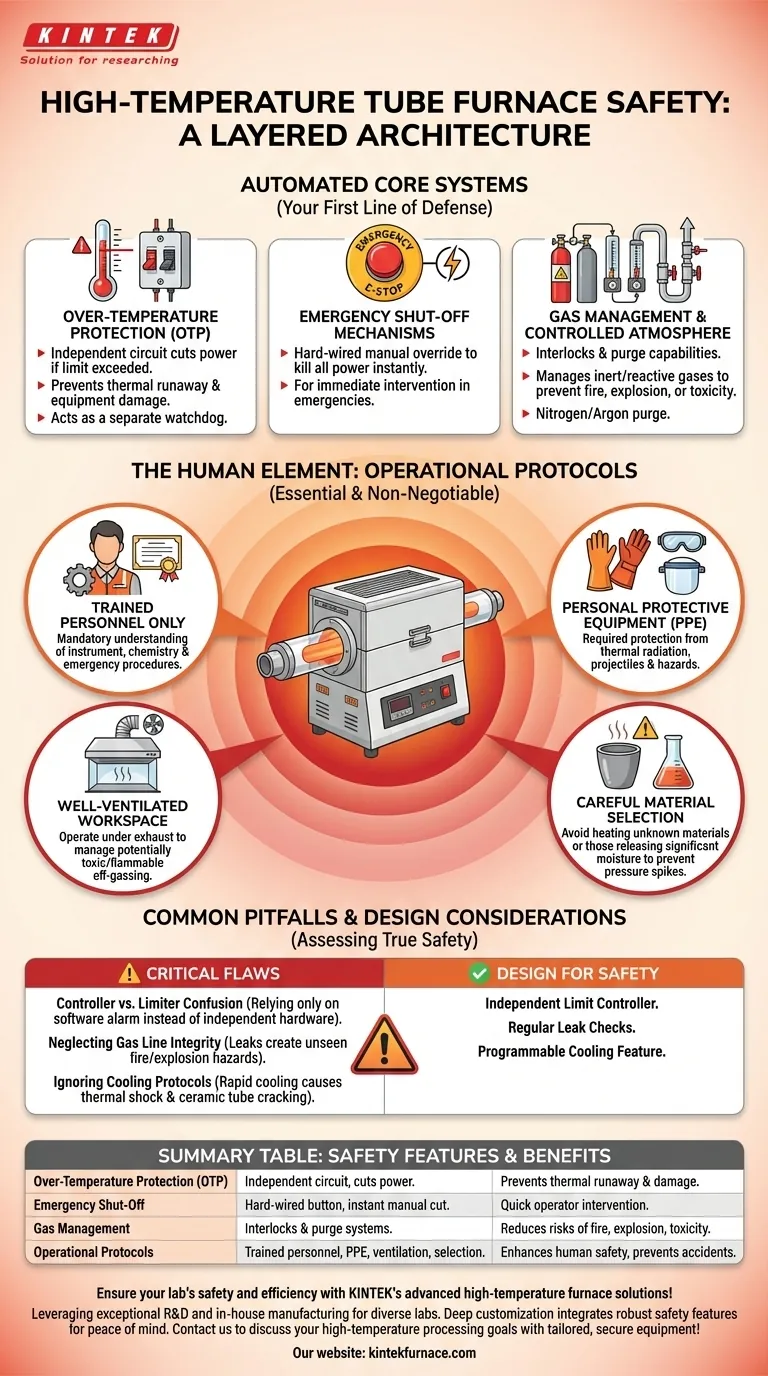

At its core, a high-temperature tube furnace is designed with a layered safety architecture to manage extreme heat and potentially volatile atmospheres. The primary built-in safety features include a dedicated over-temperature protection circuit to prevent thermal runaway, an emergency shut-off for immediate manual intervention, and systems for managing and purging process gases to prevent hazardous reactions or explosions.

A truly safe high-temperature environment is not achieved by a single feature, but by an integrated system of automated controls working in concert with disciplined operator protocols. Understanding both is essential for preventing equipment damage and ensuring personnel safety.

Understanding the Core Safety Systems

The furnace's built-in features are your first line of defense. They are designed to automatically prevent the most common and dangerous failure modes associated with high-temperature work.

Over-Temperature Protection (OTP)

This is arguably the most critical automated safety feature. While the primary PID controller actively regulates the set temperature, the OTP acts as a redundant, independent watchdog.

It uses a separate sensor to monitor the heating chamber. If the temperature exceeds a pre-set safety limit due to controller failure or any other fault, the OTP circuit will cut power to the heating elements, preventing catastrophic overheating.

Emergency Shut-Off Mechanisms

This is the user's manual override. In any unforeseen emergency—such as an unexpected sample reaction or equipment malfunction—a prominent, hard-wired emergency stop button allows the operator to instantly kill all power to the furnace.

This physical switch bypasses all software, providing a final, decisive method of halting the operation when seconds count.

Controlled Atmosphere and Gas Management

Many processes require inert, reducing, or reactive gases. These introduce risks of fire, explosion, or toxicity. Safety systems here include interlocks that prevent heating if gas flow is not detected.

Furthermore, gas purge capabilities allow the process tube to be flushed with an inert gas like nitrogen or argon before and after a run. This displaces oxygen to prevent combustion or purges residual reactive gases before the tube is opened.

The Human Element: Operational Safety Protocols

Automated features cannot account for all variables. The operator's knowledge and adherence to strict protocols are an equally important part of the overall safety system.

Trained Personnel is Non-Negotiable

Only trained and authorized personnel should ever operate a high-temperature furnace. Understanding the specific instrument, the process chemistry, and the emergency procedures is not optional.

Personal Protective Equipment (PPE)

Proper PPE is mandatory when working with or near an operating furnace. This always includes heat-resistant gloves for handling materials and safety goggles to protect from thermal radiation and potential projectile hazards.

A Well-Ventilated Workspace

Heating materials can result in off-gassing. Whether it's simple binder burnout or complex chemical reactions, these fumes can be toxic or flammable. The furnace must be operated in a well-ventilated area, often under a dedicated exhaust hood.

Careful Material Selection

Never heat unknown materials or substances that release significant moisture. Trapped moisture can vaporize and expand rapidly, causing a pressure spike that can fracture the process tube.

Common Pitfalls and Design Considerations

Not all furnace safety systems are created equal. Understanding the design nuances helps you assess the true safety level of a piece of equipment.

Controller vs. Limiter Confusion

A low-cost design might use the primary temperature controller's software alarm as its only "over-temperature protection." This is a critical flaw. A true safety system uses an independent hardware-based limit controller that functions even if the primary controller fails.

Neglecting Gas Line Integrity

The furnace's safety features assume the gas delivery system is secure. A leaking fitting on a flammable gas line (like hydrogen) can create a severe fire or explosion hazard that the furnace itself cannot detect. Regular leak-checking of all gas lines is a critical operational task.

Ignoring Cooling Protocols

The danger isn't over when the heating stops. Rapid, uncontrolled cooling can cause thermal shock, cracking the ceramic tube and exposing the still-hot interior. A furnace's programmable cooling feature is a safety tool that should be used to ensure a gradual, safe return to ambient temperature.

Making the Right Choice for Your Goal

Selecting a furnace or establishing a process requires matching the safety features to your specific application.

- If your primary focus is material synthesis with reactive gases: Prioritize furnaces with integrated gas management systems, flow interlocks, and robust purging capabilities.

- If your primary focus is high-temperature annealing in air: A reliable, independent over-temperature limit controller is your most critical safety feature.

- If you are setting up a multi-user lab environment: Invest in comprehensive operator training and clear standard operating procedures (SOPs) alongside a furnace with a prominent emergency stop.

By understanding this interplay between automated features and disciplined operation, you can leverage the power of high-temperature processing with confidence and control.

Summary Table:

| Safety Feature | Description | Key Benefit |

|---|---|---|

| Over-Temperature Protection (OTP) | Independent circuit with separate sensor to cut power if temperature exceeds safe limits | Prevents thermal runaway and equipment damage |

| Emergency Shut-Off | Hard-wired button for instant manual power cut in emergencies | Allows quick operator intervention in crises |

| Controlled Atmosphere and Gas Management | Interlocks and purge systems for safe handling of inert or reactive gases | Reduces risks of fire, explosion, and toxicity |

| Operational Protocols | Includes trained personnel, PPE, ventilation, and material selection guidelines | Enhances human safety and prevents accidents |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, integrating robust safety features for peace of mind. Contact us today to discuss how we can support your high-temperature processing goals with tailored, secure equipment!

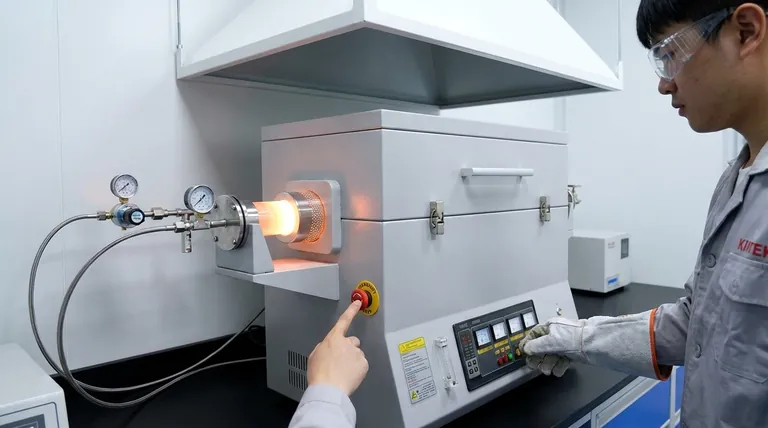

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents