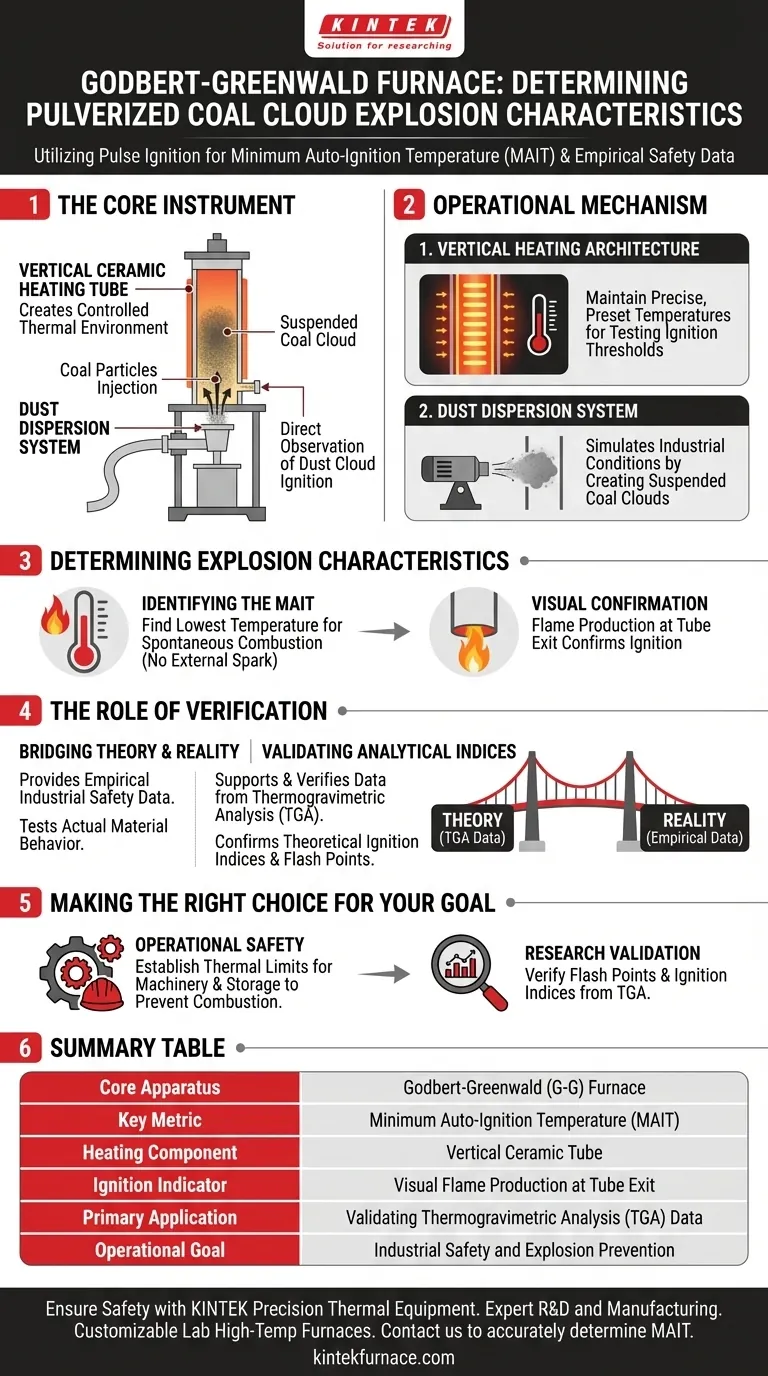

A Pulse Ignition device, typically a Godbert-Greenwald Furnace, is utilized to determine the Minimum Auto-Ignition Temperature (MAIT) of pulverized coal clouds through direct observation. The instrument operates by injecting a dust cloud into a heated vertical ceramic tube to test if flame production occurs at specific, preset temperatures.

This apparatus provides critical empirical safety data. It serves to validate theoretical ignition indices and flash points derived from thermogravimetric analysis, ensuring that safety protocols are based on observed physical reactions rather than calculations alone.

The Operational Mechanism

The Vertical Heating Architecture

The core of the Godbert-Greenwald Furnace is a vertical ceramic heating tube.

This tube creates a controlled thermal environment, allowing operators to maintain precise, preset temperatures necessary for testing ignition thresholds.

The Dust Dispersion System

To simulate a pulverized coal cloud, the device utilizes a specialized dust dispersion system.

This mechanism injects the coal particles into the heated tube, effectively creating a suspended cloud that mimics conditions found in industrial processing or storage environments.

Determining Explosion Characteristics

Identifying the MAIT

The primary output of this test is the Minimum Auto-Ignition Temperature (MAIT).

By repeatedly testing the coal cloud at varying temperatures, operators identify the lowest specific temperature at which the dust will spontaneously combust without an external spark.

Visual Confirmation

The determination of ignition is based on flame production.

Operators observe the bottom of the tube; if a flame exits the tube after the dust is injected, it confirms that the coal cloud has ignited at that specific temperature setting.

The Role of Verification

Bridging Theory and Reality

A common pitfall in safety analysis is relying solely on theoretical models.

The Pulse Ignition device is essential because it provides empirical industrial safety data. It tests the actual material behavior rather than relying on assumptions.

Validating Analytical Indices

This method is specifically used to support and verify data derived from thermogravimetric analysis.

While analytical methods provide ignition indices and calculated flash points, the Godbert-Greenwald Furnace confirms these figures through physical testing, ensuring the theoretical data holds up under simulated real-world conditions.

Making the Right Choice for Your Goal

To effectively utilize a Pulse Ignition device for pulverized coal analysis, consider your specific objective:

- If your primary focus is Operational Safety: Use the MAIT results to establish thermal limits for machinery and storage facilities to prevent spontaneous combustion.

- If your primary focus is Research Validation: Use the flame production data to verify and cross-reference the flash points and ignition indices obtained from previous thermogravimetric analyses.

This device transforms theoretical safety calculations into verified, actionable temperature limits.

Summary Table:

| Feature | Specification/Function |

|---|---|

| Core Apparatus | Godbert-Greenwald (G-G) Furnace |

| Key Metric | Minimum Auto-Ignition Temperature (MAIT) |

| Heating Component | Vertical Ceramic Tube |

| Ignition Indicator | Visual Flame Production at Tube Exit |

| Primary Application | Validating Thermogravimetric Analysis (TGA) Data |

| Operational Goal | Industrial Safety and Explosion Prevention |

Ensure the highest safety standards for your industrial processes with KINTEK’s precision thermal equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique pulverized material testing needs. Don’t rely on theoretical calculations alone; contact us today to discover how our high-performance heating solutions can help you accurately determine MAIT and protect your facility.

Visual Guide

References

- Krzysztof Czajka. Evaluation of the Reliability of Thermogravimetric Indices for Predicting Coal Performance in Utility Systems. DOI: 10.3390/en18133473

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the role of a Tube Furnace in the preparation of ferromagnetic MoS2? Master Defect Engineering & Magnetism

- How are tubular furnaces used in chemical synthesis? Unlock Precise Material Creation

- How does a high-temperature tube furnace facilitate HfOC/SiOC pyrolysis? Mastering Polymer-to-Ceramic Transition

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What does the horizontal orientation refer to in tube furnaces? Discover Its Benefits and Applications

- What advantages do drop tube furnaces offer? Achieve Precise Control and High Efficiency

- What are the specifications for three-zone and three-phase horizontal tube furnace models? Find the Perfect Fit for Your Lab

- What are the limitations of tube furnaces when cracking heavy materials? Overcome Coking and Boost Efficiency