A tubular furnace serves as the critical stabilization vessel during the preliminary carbonization of walnut shells. It provides a strictly controlled, inert environment—typically using Argon gas—to heat the biomass isothermally at 400°C, stripping away volatile organic compounds without incinerating the carbon structure.

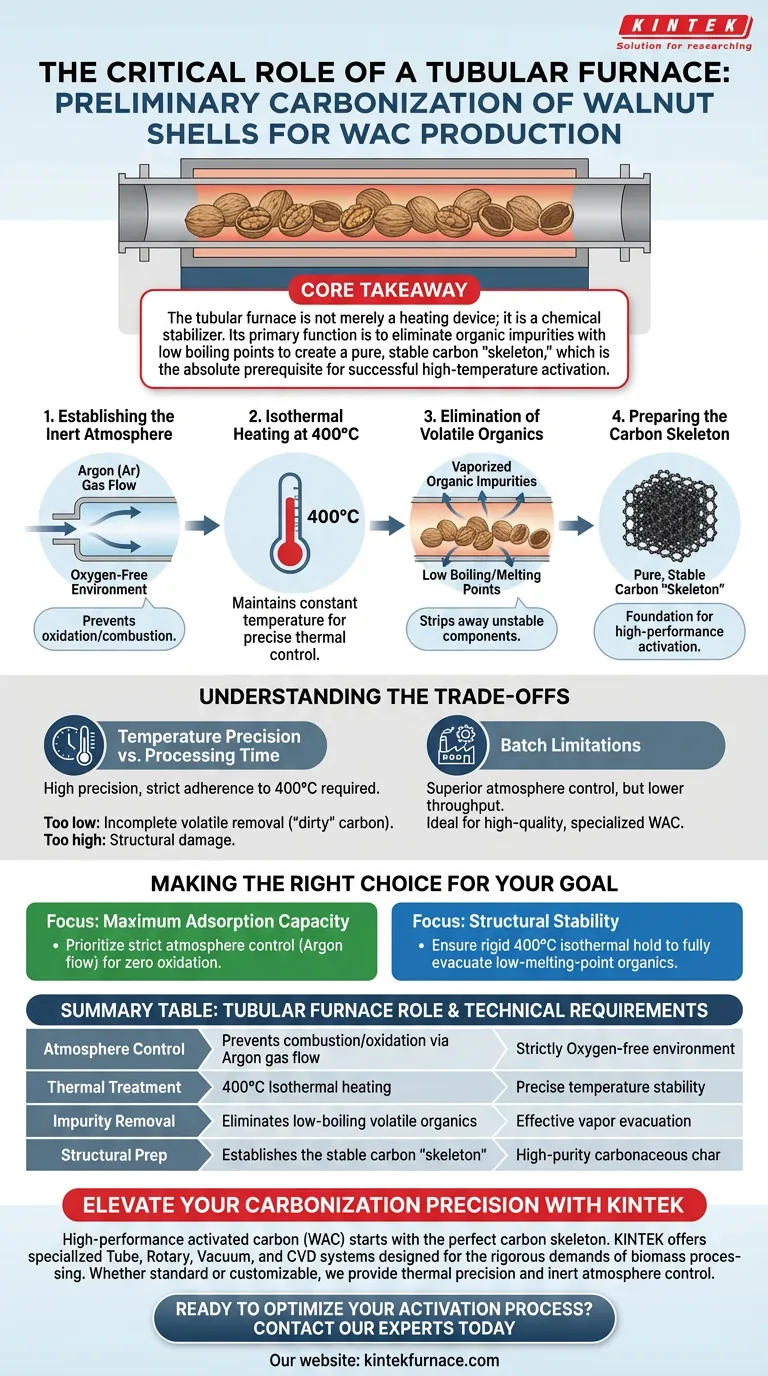

Core Takeaway The tubular furnace is not merely a heating device; it is a chemical stabilizer. Its primary function is to eliminate organic impurities with low boiling points to create a pure, stable carbon "skeleton," which is the absolute prerequisite for successful high-temperature activation.

The Mechanics of Preliminary Carbonization

Establishing the Inert Atmosphere

The most immediate role of the tubular furnace is to prevent oxidation. By maintaining a continuous flow of inert gas, such as Argon (Ar), the furnace ensures the environment is strictly oxygen-free.

Without this inert shield, heating walnut shells to hundreds of degrees would result in combustion (burning) rather than carbonization. The furnace allows thermal decomposition to occur while preserving the carbon mass.

Isothermal Heating at 400°C

According to the primary technical data, the specific target temperature for walnut shell preliminary carbonization is 400°C.

The tubular furnace maintains this specific temperature isothermally (constant temperature). This precise thermal control is necessary to target specific chemical bonds within the walnut shell biomass.

Elimination of Volatile Organics

The 400°C thermal field is calibrated to remove specific impurities. It targets organic compounds with low boiling and melting points.

As the furnace applies heat, these unstable components vaporize and are carried away by the gas flow. This leaves behind a carbonaceous char that is chemically more stable than the raw shell.

Preparing the Carbon Skeleton

This process establishes the foundation for the final product. By removing volatiles now, the furnace ensures the material has a stable structure for the subsequent, more aggressive activation phase.

If these organics were left in the shell, they would interfere with the development of micropores during later high-temperature processing.

Understanding the Trade-offs

Temperature Precision vs. Processing Time

The tubular furnace offers high precision, but it requires strict adherence to the 400°C set point.

If the temperature is too low, volatile removal is incomplete, leading to "dirty" carbon that performs poorly during activation. If the temperature spikes significantly higher during this preliminary phase, you risk damaging the structural skeleton before it is fully formed.

Batch Limitations

Tubular furnaces are generally batch or semi-continuous processing units. While they offer superior atmosphere control compared to open kilns, their throughput is often lower.

This makes them ideal for high-quality, specialized Activated Carbon production (like WAC) where purity is paramount, rather than bulk, low-grade charcoal production.

Making the Right Choice for Your Goal

To maximize the efficiency of your walnut shell carbonization, consider your specific production targets:

- If your primary focus is maximum adsorption capacity: Prioritize strict atmosphere control (Argon flow) to ensure zero oxidation of the pore structure.

- If your primary focus is structural stability: Ensure the furnace maintains a rigid 400°C isothermal hold to fully evacuate low-melting-point organics without thermal shock.

The tubular furnace transforms raw biomass into a predictable engineering material, acting as the gatekeeper between variable organic waste and high-performance activated carbon.

Summary Table:

| Stage | Key Role of Tubular Furnace | Technical Requirement |

|---|---|---|

| Atmosphere Control | Prevents combustion/oxidation via Argon gas flow | Strictly Oxygen-free environment |

| Thermal Treatment | 400°C Isothermal heating | Precise temperature stability |

| Impurity Removal | Eliminates low-boiling volatile organics | Effective vapor evacuation |

| Structural Prep | Establishes the stable carbon "skeleton" | High-purity carbonaceous char |

Elevate Your Carbonization Precision with KINTEK

High-performance activated carbon (WAC) starts with the perfect carbon skeleton. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Rotary, Vacuum, and CVD systems designed for the rigorous demands of biomass processing. Whether you need a standard lab unit or a customizable high-temperature furnace for unique walnut shell carbonization protocols, we provide the thermal precision and inert atmosphere control necessary to maximize adsorption capacity.

Ready to optimize your activation process? Contact our technical experts today to find the ideal system for your research or production needs.

Visual Guide

References

- Daniel Arenas Esteban, David Ávila‐Brande. Enhancing Electrochemical Properties of Walnut Shell Activated Carbon with Embedded MnO Clusters for Supercapacitor Applications. DOI: 10.1002/batt.202400101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What industrial applications commonly use tube furnaces? Achieve Precise Heating for Advanced Manufacturing

- How does a vertical tube furnace ensure effective hydrogen reduction reactions? Optimize Rare Earth Tailing Processing

- What is the function of a tube reduction furnace? Enhance Ru@PG Catalysts with Ar/H2 Precision

- What are the specific calcination requirements for a tubular resistance furnace for NCM622? Expert Synthesis Guide

- What are the key features of a modern tube furnace? Precision, Control, and Versatility for Advanced Labs

- What role does a vacuum tube furnace play in AlCrSiWN coating annealing? Enhance Stability and Hardness

- How does a dual-zone tube furnace facilitate monolayer synthesis? Precision Growth for MoS2 & WS2

- What materials are commonly processed in tube furnaces for powder forming and sintering? Unlock Precision for Advanced Materials