A vacuum tube furnace serves as the critical instrument for post-deposition thermal management. It provides a precisely controlled high-temperature environment, utilizing integrated PID controllers to execute complex multi-stage heating and isothermal holding programs. This process is essential for eliminating brittle residual stresses, inducing self-hardening effects, and significantly improving the thermal stability of AlCrSiWN coatings.

Core Takeaway While the deposition process creates the coating, the vacuum tube furnace refines its mechanical integrity. By executing precise heating profiles, the furnace transforms a stressed, brittle layer into a thermally stable, hardened surface capable of withstanding rigorous operational conditions.

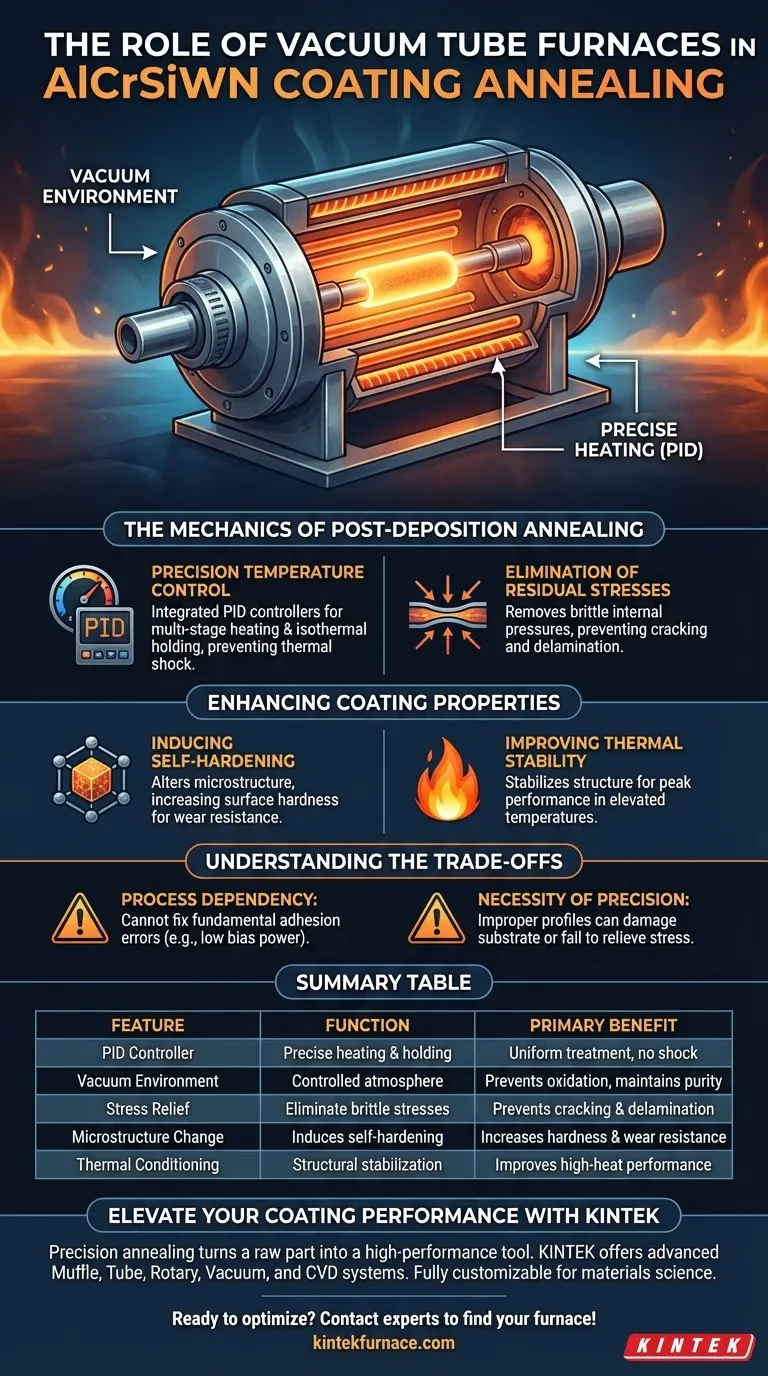

The Mechanics of Post-Deposition Annealing

Precision Temperature Control

The effectiveness of the vacuum tube furnace lies in its ability to maintain a strictly controlled environment.

It employs an integrated PID controller to manage the heating process. This allows for the execution of specific multi-stage heating programs and isothermal holding periods, ensuring the coating is treated uniformly without thermal shock.

Elimination of Residual Stresses

During the deposition phase, coatings often develop significant internal pressure.

While bias power supplies help regulate stress during the initial application, the vacuum tube furnace is required to eliminate brittle residual stresses that remain after the process is complete. This step prevents the coating from cracking or delaminating under load.

Enhancing Coating Properties

Inducing Self-Hardening

Beyond simply relieving stress, the furnace actively alters the microstructure of the AlCrSiWN coating.

The heat treatment process induces self-hardening effects. This structural evolution increases the coating's surface hardness, making it more resistant to wear and abrasion during use.

Improving Thermal Stability

For coatings used in high-heat applications, stability is paramount.

The vacuum tube furnace conditions the material to withstand elevated temperatures. By stabilizing the coating structure in a controlled vacuum, it improves the overall thermal stability, ensuring the coating retains its properties even when exposed to operational heat.

Understanding the Trade-offs

Process Dependency

The vacuum tube furnace cannot fix fundamental adhesion errors.

Factors like coating density and substrate adhesion are determined by the bias power supply during deposition. If the initial atomic mixing effect was insufficient, annealing in a furnace will not correct the underlying lack of adhesion.

The Necessity of Precision

The benefits of annealing are entirely dependent on the accuracy of the heating profile.

Improper heating or incorrect isothermal holding times can fail to relieve stress or, conversely, alter the substrate's properties negatively. The PID controller is not just a feature; it is a safeguard against destroying the component during its final processing stage.

Making the Right Choice for Your Goal

To maximize the performance of your AlCrSiWN coatings, align your thermal treatment with your specific performance metrics.

- If your primary focus is Durability and Toughness: Prioritize the elimination of brittle residual stresses to prevent premature cracking under mechanical load.

- If your primary focus is High-Temperature Operation: Focus on the isothermal holding programs that enhance thermal stability, ensuring the coating survives in hot environments.

Precise post-deposition annealing turns a raw coated part into a high-performance industrial tool.

Summary Table:

| Feature | Function in AlCrSiWN Annealing | Primary Benefit |

|---|---|---|

| PID Controller | Precise multi-stage heating & isothermal holding | Ensures uniform treatment & prevents thermal shock |

| Vacuum Environment | Controlled high-temperature atmosphere | Prevents oxidation and maintains material purity |

| Stress Relief | Elimination of brittle residual stresses | Prevents cracking and delamination under load |

| Microstructure Change | Induces self-hardening effects | Increases surface hardness and wear resistance |

| Thermal Conditioning | Structural stabilization | Improves performance in high-heat applications |

Elevate Your Coating Performance with KINTEK

Precision annealing is the difference between a brittle layer and a high-performance industrial tool. KINTEK provides the advanced thermal solutions necessary to unlock the full potential of your AlCrSiWN coatings.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need to eliminate residual stress or enhance thermal stability, our high-temp lab furnaces are fully customizable to meet your unique materials science requirements.

Ready to optimize your thermal management? Contact our experts today to find the perfect furnace for your lab.

Visual Guide

References

- Feng Guo. Research on the Performance of AlCrSiWN Tool Coatings for Hardened Steel Cutting. DOI: 10.62051/ijmee.v6n2.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What is the recommended procedure for atmosphere control in a vacuum tube furnace? Optimize Your High-Temperature Processes

- What temperature range and applications is this tube furnace suitable for? Ideal for 500°C to 1800°C thermal processes

- How does a high-temperature tube furnace contribute to the pore regulation of carbon nanofibers? Precision Engineering

- What Role Does a Tube Reactor Play in Food Waste Pyrolysis? Control Carbonization for High-Quality Biochar

- What is the function of a tube furnace in the synthesis of g-C3N4? Master Thermal Exfoliation for High-Surface Area

- Why is a nitrogen atmosphere required in a high-temperature tube furnace during the preparation of Co-HCC nanoparticles?

- What is the principle of tube furnace? Master Precise High-Temp Environment Control