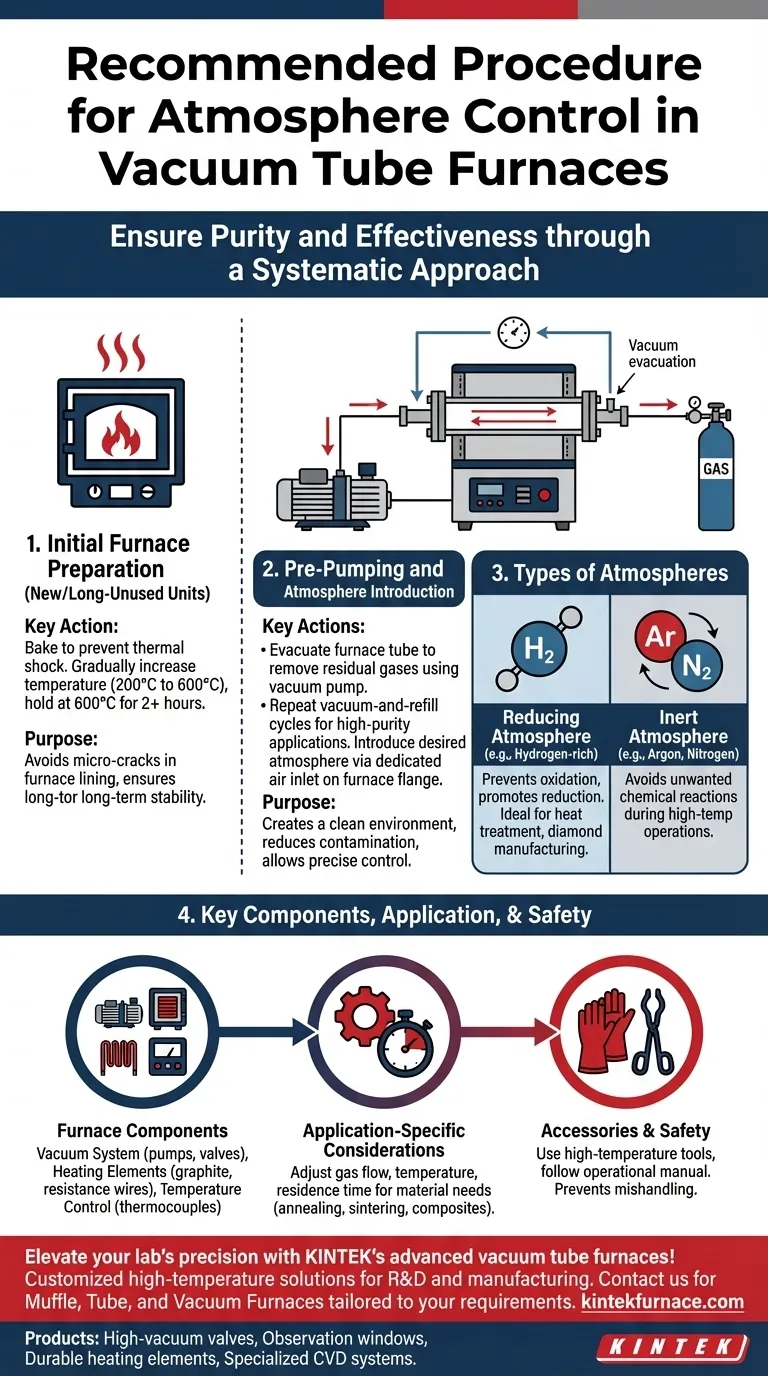

The recommended procedure for atmosphere control in a vacuum tube furnace involves a systematic approach to ensure purity and effectiveness. Key steps include pre-pumping a vacuum to remove residual gases, introducing the desired atmosphere, and potentially repeating this cycle for enhanced purity. The process also considers the type of atmosphere (e.g., reducing or inert), furnace components, and specific application requirements like temperature and material properties. Proper handling of accessories and initial furnace preparation (like baking for new units) further ensures optimal performance.

Key Points Explained:

-

Pre-Pumping and Atmosphere Introduction

- Begin by evacuating the furnace tube using a vacuum pump to remove any residual gases. This step is critical for creating a clean environment before introducing the desired atmosphere.

- For high-purity applications, repeat the vacuum-and-refill cycle several times. This reduces contamination and ensures a more controlled atmosphere.

- The atmosphere can be introduced through a dedicated air inlet on the furnace flange, allowing precise control over gas composition (e.g., hydrogen for reduction or inert gases like argon).

-

Types of Atmospheres

- Reducing Atmosphere: Used to prevent oxidation and promote reduction (e.g., hydrogen-rich environments). Ideal for processes like heat treatment or diamond manufacturing.

- Inert Atmosphere: Gases like argon or nitrogen are introduced to avoid unwanted chemical reactions during high-temperature operations.

-

Furnace Components and Their Roles

- Vacuum System: Comprises mechanical pumps, molecular pumps, and valves to achieve and maintain the desired vacuum level.

- Heating Elements: Materials like graphite or resistance wires heat the furnace while operating under controlled atmospheres.

- Temperature Control: Thermocouples and controllers ensure precise temperature profiles, which are critical for processes like annealing or sintering.

-

Initial Furnace Preparation

- New or long-unused furnaces require baking to prevent thermal shock. Gradually increase the temperature (e.g., 200°C to 600°C) and hold at 600°C for at least two hours.

- This step avoids micro-cracks in the furnace lining and ensures long-term stability.

-

Application-Specific Considerations

- For processes like annealing, the atmosphere must align with the material’s needs (e.g., stress relief or grain refinement).

- Customizable parameters (e.g., temperature, gas flow rate, and residence time) are critical for specialized applications like composite sheet production.

-

Accessories and Safety

- Use high-temperature gloves and tongs for handling hot components.

- Follow the operational manual for specific furnace models to avoid mishandling.

By integrating these steps, users can achieve precise atmosphere control, tailored to their material and process requirements. Have you considered how small adjustments in gas flow or vacuum cycles might impact your final product quality? These nuances often define the success of high-temperature experiments.

Summary Table:

| Step | Key Actions | Purpose |

|---|---|---|

| Pre-Pumping | Evacuate residual gases using a vacuum pump; repeat cycles for high purity. | Creates a clean environment before introducing the desired atmosphere. |

| Atmosphere Introduction | Introduce reducing (e.g., hydrogen) or inert gases (e.g., argon) via inlet. | Prevents oxidation or unwanted reactions during high-temperature processes. |

| Furnace Preparation | Bake new/unused furnaces (200°C–600°C) to prevent thermal shock. | Ensures long-term stability and avoids micro-cracks. |

| Application-Specific | Adjust gas flow, temperature, and residence time for materials like composites. | Tailors the process to material needs (e.g., annealing, sintering). |

| Safety & Accessories | Use high-temperature gloves/tongs; follow operational manuals. | Prevents mishandling and ensures safe operation. |

Elevate your lab’s precision with KINTEK’s advanced vacuum tube furnaces! Our expertise in R&D and in-house manufacturing allows us to deliver customized high-temperature solutions, including Muffle, Tube, and Vacuum Furnaces, tailored to your unique requirements. Whether you need a reducing atmosphere for diamond synthesis or inert gas control for sensitive materials, we’ve got you covered. Contact us today to discuss how our solutions can enhance your process efficiency and product quality!

Products You Might Be Looking For:

High-vacuum valves for gas control

Observation windows for real-time monitoring

Durable heating elements for extreme temperatures

Specialized CVD systems for diamond growth

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents