Three-zone tube furnaces are in high demand because they provide an exceptional level of thermal precision that is essential for synthesizing and processing advanced materials. Unlike single-zone models, their segmented heating capability allows researchers and engineers to either create an extended, highly uniform temperature zone or establish precise, stable temperature gradients, a flexibility that unlocks complex manufacturing processes and ensures reproducible, high-quality results.

The critical advantage of a three-zone furnace is not just more power, but absolute control over the temperature profile. This control is the key that enables sophisticated processes like Chemical Vapor Deposition (CVD) and the creation of next-generation materials that are impossible to produce with simpler equipment.

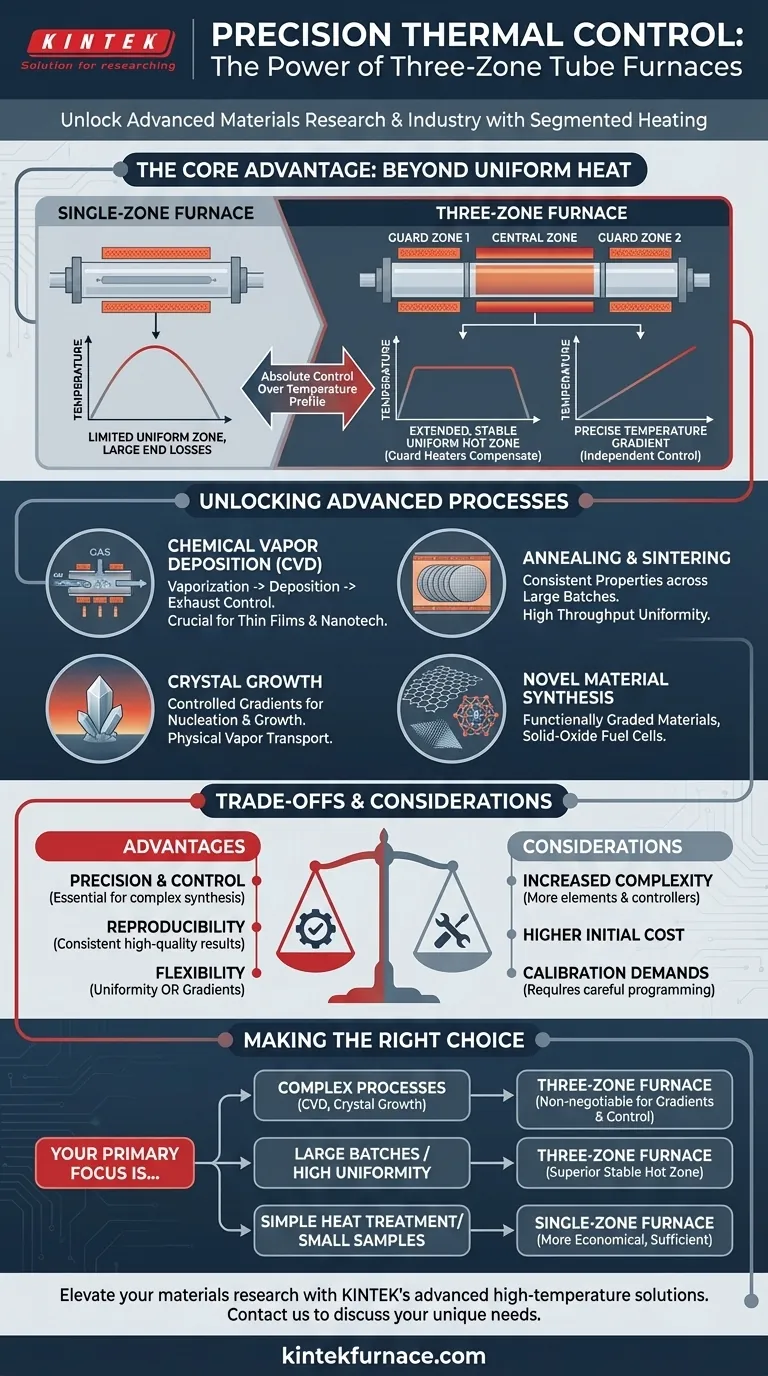

The Core Advantage: Moving Beyond Uniform Heat

The defining feature of a three-zone furnace is its ability to manipulate the thermal environment across the length of the process tube. This is achieved through three independent heating zones, each with its own controller and thermocouple.

Achieving Superior Temperature Uniformity

In any tube furnace, heat naturally escapes from the ends of the tube. A single-zone furnace has one hot zone in the middle that tapers off significantly toward the cooler ends.

A three-zone furnace solves this by using the two outer zones as "guard" heaters. By setting them to a slightly higher temperature, they compensate for the end losses, creating a much larger and more stable uniform hot zone in the central section. This is critical for processes where every part of a sample must experience the exact same temperature.

Creating Precise Temperature Gradients

Conversely, the independent zones can be programmed to different setpoints to create a stable, linear temperature gradient.

This allows for processes where a material must move through different temperatures in a controlled sequence or for the study of temperature-dependent phenomena. This capability is fundamental for advanced techniques like physical vapor transport and specific types of crystal growth.

Unlocking Advanced Material Processes

This precise thermal control directly enables processes that are foundational to modern technology and research.

Enabling Chemical Vapor Deposition (CVD)

CVD is a cornerstone of semiconductor and nanotechnology manufacturing. A three-zone furnace is ideal for this process.

One zone can be used to heat and vaporize a precursor material, the central zone can hold the substrate at the exact deposition temperature, and the third zone can control the temperature of the exhaust region. This zonal separation is crucial for controlling the reaction kinetics and achieving high-quality thin films.

Perfecting Annealing and Crystal Growth

For applications like annealing semiconductor wafers or sintering ceramics, uniformity is paramount. The extended uniform zone of a three-zone furnace allows for the processing of larger samples or larger batches of small samples, ensuring consistent material properties and higher throughput.

For specialized crystal growth, a controlled gradient is often required to initiate nucleation in one area and promote growth in another.

Synthesizing Novel Material Architectures

The ability to program complex thermal profiles supports the creation of advanced materials. This includes functionally graded materials, where properties change along their length, and the synthesis of complex structures like graphene, photonic crystals, and components for solid-oxide fuel cells.

Understanding the Trade-offs and Considerations

While powerful, a three-zone furnace is not always the default choice. Objectivity requires acknowledging its complexities.

Increased Cost and Complexity

A three-zone furnace has more heating elements, controllers, and thermocouples. This inherently increases the initial purchase cost and the complexity of operation and maintenance compared to a single-zone unit.

Calibration and Programming Demands

Achieving a perfectly flat uniform zone or a precise linear gradient is not automatic. It requires careful initial calibration and more thoughtful programming to ensure the three zones work in concert to produce the desired profile.

When a Single Zone is Sufficient

For simple applications like basic heat treatment, thermal decomposition of a small sample, or proof-of-concept tests where absolute uniformity over a large area is not critical, a single-zone furnace is often a more practical and cost-effective solution.

Making the Right Choice for Your Application

Choosing the correct furnace is an investment in your process capability. Your decision should be driven by the specific demands of your materials and goals.

- If your primary focus is complex processes like CVD or crystal growth: A three-zone furnace is non-negotiable for its essential ability to create and hold stable temperature gradients.

- If your primary focus is processing large samples or batches with high uniformity: A three-zone furnace provides a significantly larger and more stable uniform hot zone, ensuring consistent and reproducible results.

- If your primary focus is simple heat treatment or developing new processes on small samples: A more economical single-zone furnace may be sufficient for your needs while you validate your parameters.

Ultimately, selecting a three-zone furnace is an investment in process control, precision, and the potential to create next-generation materials.

Summary Table:

| Feature | Benefit |

|---|---|

| Three Independent Heating Zones | Enables precise temperature gradients and uniform heating for complex processes |

| Guard Heaters | Compensates for end losses, creating large, stable uniform hot zones |

| Flexible Programming | Supports advanced techniques like CVD, annealing, and crystal growth |

| Enhanced Control | Improves reproducibility and quality in material synthesis and processing |

Ready to elevate your materials research with precision thermal control? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're working on CVD, annealing, or crystal growth, our three-zone tube furnaces can help you achieve superior results. Contact us today to discuss how we can support your innovative projects!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide