At its core, a horizontal furnace derives its versatility from a design that masterfully combines three critical elements: a large processing volume, highly uniform heating, and precise atmospheric and thermal control. This combination allows a single piece of equipment to serve as a reliable workhorse for a wide range of industrial and scientific applications, from heat-treating metals to manufacturing advanced semiconductors.

Choosing the right thermal processing equipment requires moving beyond a simple list of features. The true versatility of a horizontal furnace isn't just in what it can do, but in its fundamental ability to deliver exceptionally uniform results at scale, making it a cost-effective and adaptable solution for high-volume production.

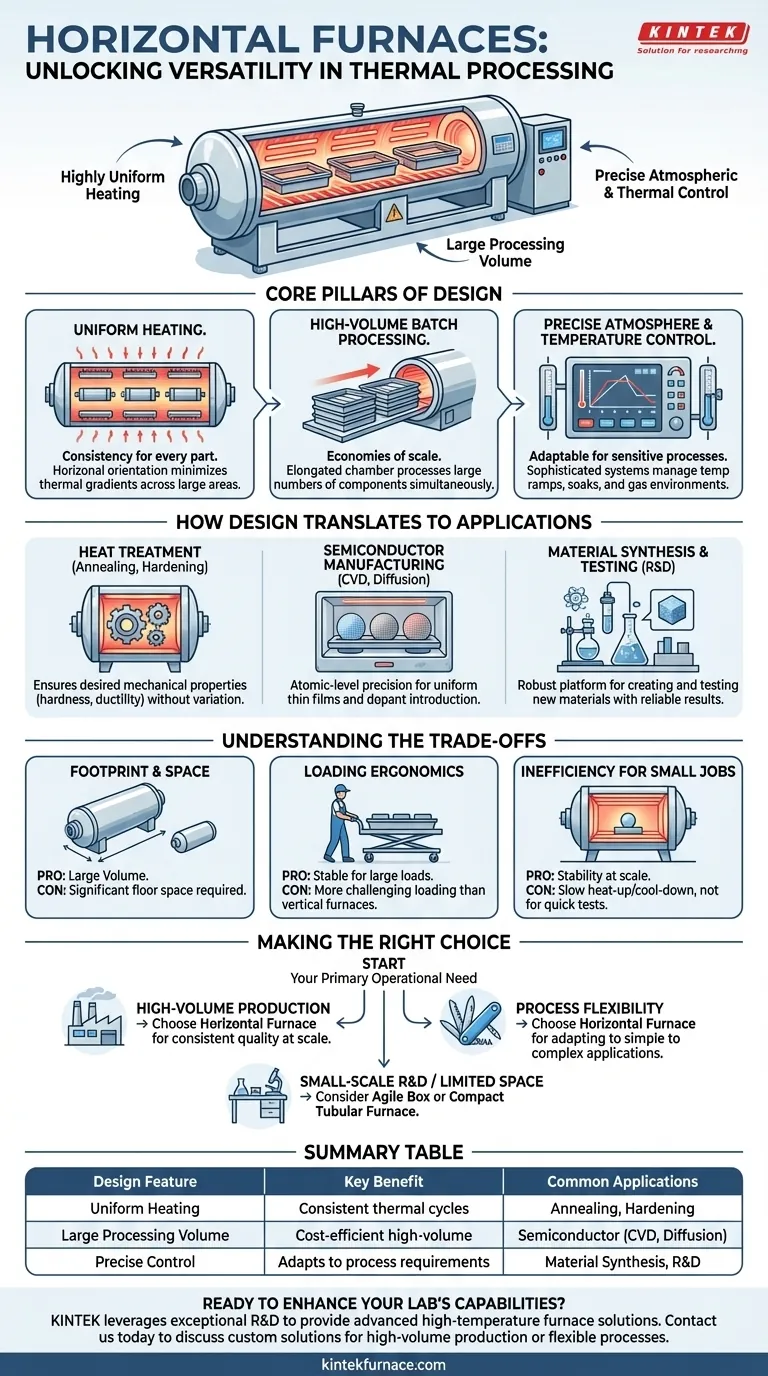

The Core Pillars of Horizontal Furnace Design

The versatility of a horizontal furnace is not an accident; it is the direct result of intentional design choices that prioritize consistency, capacity, and control.

Uniform Heating Across a Large Area

The horizontal tube or chamber design, surrounded by carefully configured heating elements, is engineered for one primary purpose: thermal uniformity.

Unlike some vertical designs where convection can create temperature gradients, the horizontal orientation allows for a more stable and predictable thermal environment along the entire length of the processing area. This ensures that every part in a large batch experiences the exact same thermal cycle.

High-Volume Batch Processing

A key advantage is the ability to process a large number of components simultaneously. This high-volume capability is a direct function of the furnace's elongated chamber.

By processing large batches instead of single items or small groups, manufacturers achieve significant economies of scale. This reduces the cost per part, saves energy, and increases overall throughput, making it an economically sound choice for production environments.

Precise Temperature & Atmosphere Control

True versatility comes from the ability to adapt to different process requirements. Modern horizontal furnaces integrate sophisticated control systems to manage both temperature and atmosphere.

This includes programmable thermostats and timers for precise temperature ramps and soaks, as well as systems for introducing, purging, and maintaining specific gases. This control is what enables the furnace to handle sensitive processes like chemical vapor deposition (CVD) just as easily as basic annealing.

How Design Translates to Versatile Applications

These core design pillars enable the horizontal furnace to excel in a diverse set of demanding applications.

For Heat Treatment (Annealing, Hardening)

In metallurgy, the final properties of a material are dictated by its thermal history. The uniform heating of a horizontal furnace ensures that every component in a batch achieves the desired hardness, ductility, or stress relief without variation.

For Semiconductor Manufacturing (CVD, Diffusion)

Fabricating microchips requires atomic-level precision. The pristine atmospheric control and thermal stability of a horizontal furnace are essential for processes like depositing uniform thin films (CVD) or introducing dopants into silicon wafers (diffusion).

For Material Synthesis and Testing

In research and development, creating or testing new materials often requires subjecting them to harsh conditions. The robust construction and highly controlled environment of a horizontal furnace make it an ideal platform for these experiments, providing reliable and repeatable results.

Understanding the Trade-offs

No design is without its compromises. Understanding the limitations of a horizontal furnace is critical for making an informed decision.

Footprint and Space Requirements

The "large volume" advantage comes with a direct trade-off: a large physical footprint. These furnaces require significant floor space, which can be a constraint in smaller labs or crowded facilities.

Loading and Unloading Ergonomics

Loading and unloading long process tubes or heavy product "boats" into a horizontal chamber can be more challenging than simply placing an item onto the hearth of a box furnace with a vertical-lift door. This may require specialized carts or automation for heavy loads.

Inefficiency for Small, Single-Item Jobs

The large thermal mass that contributes to stability also means the furnace can be slow to heat up and cool down. For quick tests on a single, small sample, a smaller muffle or compact tubular furnace is often a more energy-efficient and faster choice.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary operational need.

- If your primary focus is high-volume production: The horizontal furnace's batch capacity and exceptional thermal uniformity make it the superior choice for ensuring consistent quality at scale.

- If your primary focus is process flexibility: The ability to precisely control both temperature and atmosphere allows this furnace to adapt to a wide range of applications, from simple to complex.

- If your primary focus is small-scale R&D or you have limited space: A smaller, more agile box furnace or dedicated tubular furnace may better serve your need for quick thermal cycles and a minimal footprint.

Ultimately, selecting the right furnace is about aligning its fundamental design principles with the specific demands of your process.

Summary Table:

| Design Feature | Key Benefit | Common Applications |

|---|---|---|

| Uniform Heating | Ensures consistent thermal cycles across large areas | Annealing, hardening of metals |

| Large Processing Volume | Supports high-volume batch processing for cost efficiency | Semiconductor manufacturing (CVD, diffusion) |

| Precise Temperature & Atmosphere Control | Allows adaptation to various process requirements | Material synthesis, R&D testing |

Ready to enhance your lab's capabilities with a versatile horizontal furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for high-volume production or flexible processes. Contact us today to discuss how our solutions can bring efficiency and precision to your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key function of a tube furnace for AHSS austenitization? Precision Testing for High-Strength Steel

- How does the environmental control of a high-temperature tube furnace affect the calcination of alpha-MoO3 powder?

- What types of applications are tube furnaces suitable for? Ideal for Precise Thermal Processing in Labs

- What are the main advantages of a vertical tube furnace? Superior Purity, Uniformity, and Space Savings

- How do tube furnaces provide precise and uniform heating? Unlock Consistent Thermal Processing

- Why is an industrial monitoring camera necessary for measuring aluminum powder ignition delay in a tube furnace?

- What is the purpose of using forming gas (N2/H2) in a tube furnace? Achieve High-Purity Cr3+-Activated LiScO2 Phosphors

- What are the steps for insulation and cooling in a multi zone tube furnace? Master Precise Thermal Control