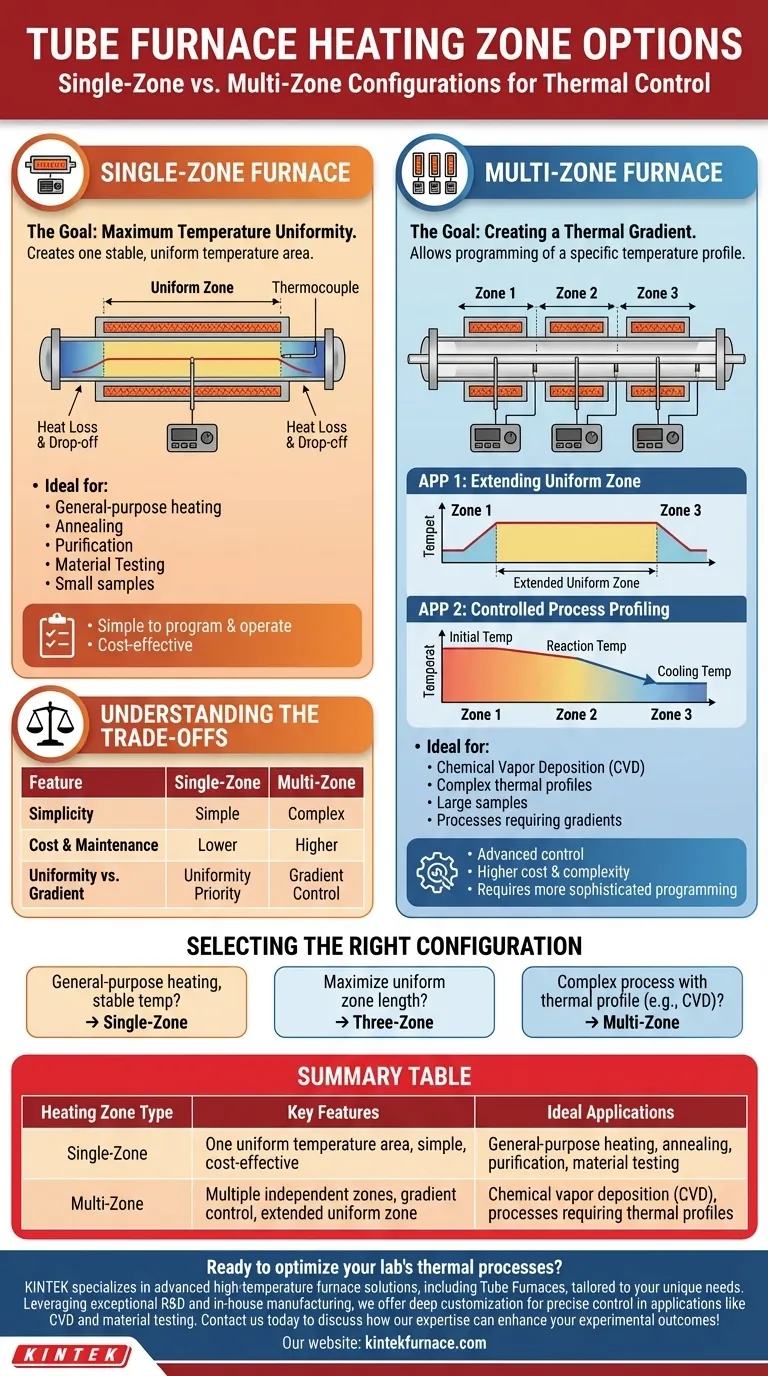

In essence, tube furnaces are configured with either a single heating zone or multiple, independently controlled heating zones. A single-zone furnace is designed to create one stable, uniform temperature area. In contrast, a multi-zone furnace allows you to create a more complex temperature profile or extend the length of the uniform temperature zone along the process tube.

The choice between single-zone and multi-zone is not about which is "better," but which tool provides the right thermal control for your specific process. Single-zone furnaces prioritize simplicity and uniformity, while multi-zone furnaces offer advanced control over temperature gradients.

The Role of a Single-Zone Furnace

A single-zone furnace is the most common and straightforward configuration, built around one set of heating elements managed by a single temperature controller.

The Goal: Maximum Temperature Uniformity

The primary purpose of a single-zone design is to heat a sample to a specific temperature and hold it there with high stability. The controller works to maintain the setpoint in the center of the heated length.

Understanding the "Uniform Zone"

It is critical to understand that the entire heated length is not perfectly uniform. Heat naturally escapes from the ends of the furnace tube, creating a temperature drop-off. The "uniform zone" is the central region where the temperature is stable and matches the controller's setpoint.

Ideal Applications

Single-zone furnaces are ideal for processes like general-purpose heating, annealing, purification, and material testing, where the sample is small enough to fit within the central uniform zone.

The Power of a Multi-Zone Furnace

Multi-zone furnaces divide the heated length into several sections (most commonly three) where each zone has its own heating elements and independent temperature controller.

The Goal: Creating a Thermal Gradient

This independent control is the key advantage. It allows you to program a specific temperature profile along the length of the tube, where different sections are held at different temperatures simultaneously.

Application 1: Extending the Uniform Zone

A crucial application for a three-zone furnace is to create a larger uniform temperature zone. By setting the outer "slave" zones to a slightly higher temperature, you can compensate for the heat loss at the ends, effectively extending the length of the central "master" zone's uniform temperature area.

Application 2: Controlled Process Profiling

Multi-zone furnaces are essential for advanced processes like chemical vapor deposition (CVD). These processes often require a gradient where reactants are heated to one temperature in an initial zone, react at a different temperature in a central zone, and cool at a controlled rate in a final zone.

Understanding the Trade-offs

Choosing the right configuration requires a clear understanding of the compromises between simplicity, performance, and cost.

Simplicity vs. Complexity

A single-zone furnace is simple to program and operate. A multi-zone furnace requires more sophisticated programming to manage the different zone setpoints and achieve the desired thermal profile.

Cost and Maintenance

With more heating elements, controllers, and thermocouples, a multi-zone furnace has a higher initial purchase price. It also presents greater complexity for maintenance and troubleshooting over the lifetime of the equipment.

Uniformity vs. Gradient Control

The decision ultimately comes down to your core need. If your goal is to hold one temperature very steady for a sample in the center, a single-zone furnace is efficient and effective. If you need to control temperatures over a longer length or create a gradient, a multi-zone furnace is necessary.

Selecting the Right Configuration for Your Process

Your process requirements should be the sole driver of your decision.

- If your primary focus is general-purpose heating at a single, stable temperature: A single-zone furnace provides the best balance of performance, cost, and simplicity.

- If your primary focus is maximizing the length of the uniform temperature zone: A three-zone furnace is the superior choice, as the end zones can be programmed to compensate for heat loss.

- If your primary focus is a complex process like CVD requiring a specific temperature profile: A multi-zone furnace is essential to create the necessary thermal gradient along the tube.

By understanding the fundamental difference between uniform heating and gradient control, you can confidently select the furnace configuration that directly serves your scientific or industrial goal.

Summary Table:

| Heating Zone Type | Key Features | Ideal Applications |

|---|---|---|

| Single-Zone | One uniform temperature area, simple operation, cost-effective | General-purpose heating, annealing, purification, material testing |

| Multi-Zone | Multiple independent zones, gradient control, extended uniform zone | Chemical vapor deposition (CVD), processes requiring thermal profiles |

Ready to optimize your lab's thermal processes? KINTEK specializes in advanced high-temperature furnace solutions, including Tube Furnaces, tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization for precise control in applications like CVD and material testing. Contact us today to discuss how our expertise can enhance your experimental outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab