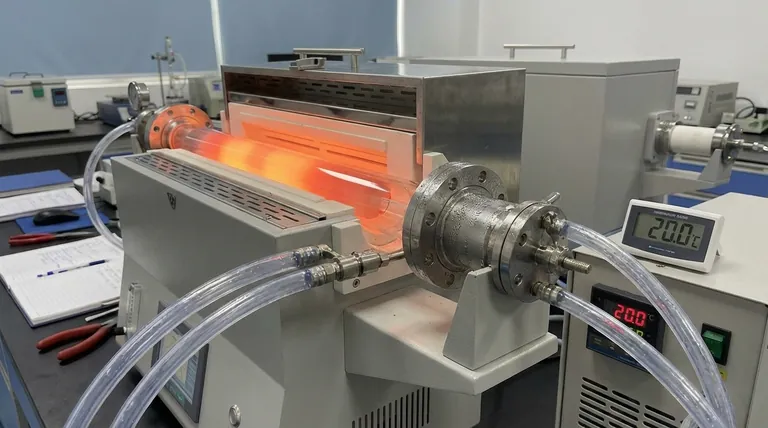

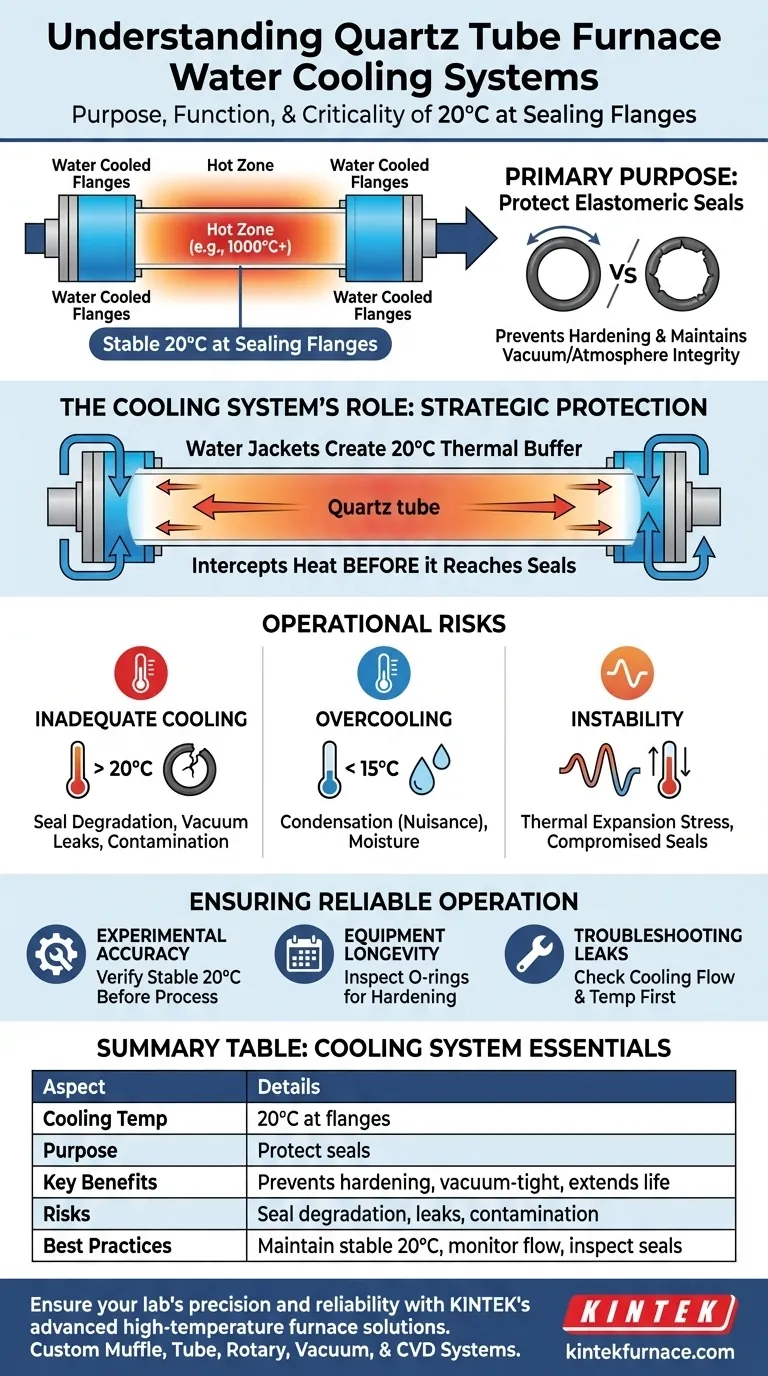

In a typical quartz tube furnace, the water cooling system is specifically designed to maintain a stable temperature of 20° C at the sealing flanges. This precise temperature is not for cooling the central hot zone, but is a critical parameter for ensuring the long-term operational integrity and atmospheric purity of the furnace.

The primary purpose of the 20° C water cooling is to protect the furnace's elastomeric seals from heat damage. By keeping these components at a stable room temperature, the system prevents them from hardening, which preserves the vacuum-tight or controlled atmosphere essential for high-integrity experiments.

The Role of the Cooling System: Beyond Just Cooling

Many assume the water cooling system's job is to manage the extreme heat of the furnace core. In reality, its function is far more localized and strategic, focused entirely on the ends of the process tube.

Protecting Sealing Integrity

A quartz tube furnace relies on sealing flanges at both ends to isolate its internal environment. These seals, often made of materials like Viton or silicone O-rings, are what allow for high-vacuum or controlled gas atmospheres.

Heat from the central furnace chamber inevitably conducts along the quartz tube towards these end flanges. The cooling system's job is to intercept and remove this heat before it reaches the seals.

The Problem: Heat-Induced Hardening

Elastomeric seals are vulnerable to heat. When exposed to temperatures well above room temperature, they lose their flexibility and become hard and brittle.

A hardened seal can no longer compress properly to create an airtight barrier. This degradation is the primary cause of vacuum leaks and contamination of the furnace's internal atmosphere, which can ruin sensitive processes.

The Solution: A Stable 20° C Environment

Water cooling jackets are integrated into the end flanges to create a constant thermal buffer. By circulating water at a steady 20° C, the system keeps the seals well within their safe operating temperature range.

This prevents thermal degradation, significantly extends the life of the seals, and ensures the furnace can perform its core function reliably over many cycles.

Understanding the Operational Risks

Failing to manage the cooling system properly is one of the most common sources of error and equipment failure in tube furnace operations.

Risk of Inadequate Cooling

If the water temperature rises significantly above 20° C or the flow rate is insufficient, the seals will begin to degrade. The first sign is often a gradual inability to achieve a deep vacuum or the need for more frequent seal replacements. This is the most critical risk to monitor.

Risk of Overcooling

Using water that is too cold (e.g., chilled to near-freezing) can cause condensation to form on the exterior of the flanges, especially in a humid lab environment. While less damaging than overheating, this moisture can be a nuisance and is best avoided by targeting the 20° C setpoint.

The Importance of Stability

A stable temperature is as important as the target number itself. Temperature fluctuations cause the different materials in the flange assembly (metal, quartz, elastomer) to expand and contract at different rates, which can stress the seals and compromise their integrity over time.

Ensuring Reliable Furnace Operation

Understanding this principle allows you to shift from simply operating the furnace to actively managing its performance and longevity.

- If your primary focus is experimental accuracy: Always verify your cooling system is active and stable at 20° C before starting a high-vacuum or controlled-atmosphere process.

- If your primary focus is equipment longevity: Regularly inspect your sealing O-rings for signs of hardening or cracking, as this is the first indicator that your cooling system may be underperforming.

- If your primary focus is troubleshooting leaks: A sudden or gradual failure to hold vacuum is most often linked to seal degradation, making the cooling system's temperature and flow the first variables you should investigate.

Properly managing your furnace's cooling system is the foundation for achieving repeatable, high-integrity results.

Summary Table:

| Aspect | Details |

|---|---|

| Cooling Temperature | 20°C at sealing flanges |

| Purpose | Protect elastomeric seals from heat damage |

| Key Benefits | Prevents hardening, ensures vacuum-tight seals, extends equipment life |

| Risks of Improper Cooling | Seal degradation, vacuum leaks, contamination |

| Best Practices | Maintain stable 20°C, monitor flow rate, inspect seals regularly |

Ensure your lab's precision and reliability with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements, enhancing efficiency and preventing issues like seal failures. Contact us today to discuss how we can support your high-integrity processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis