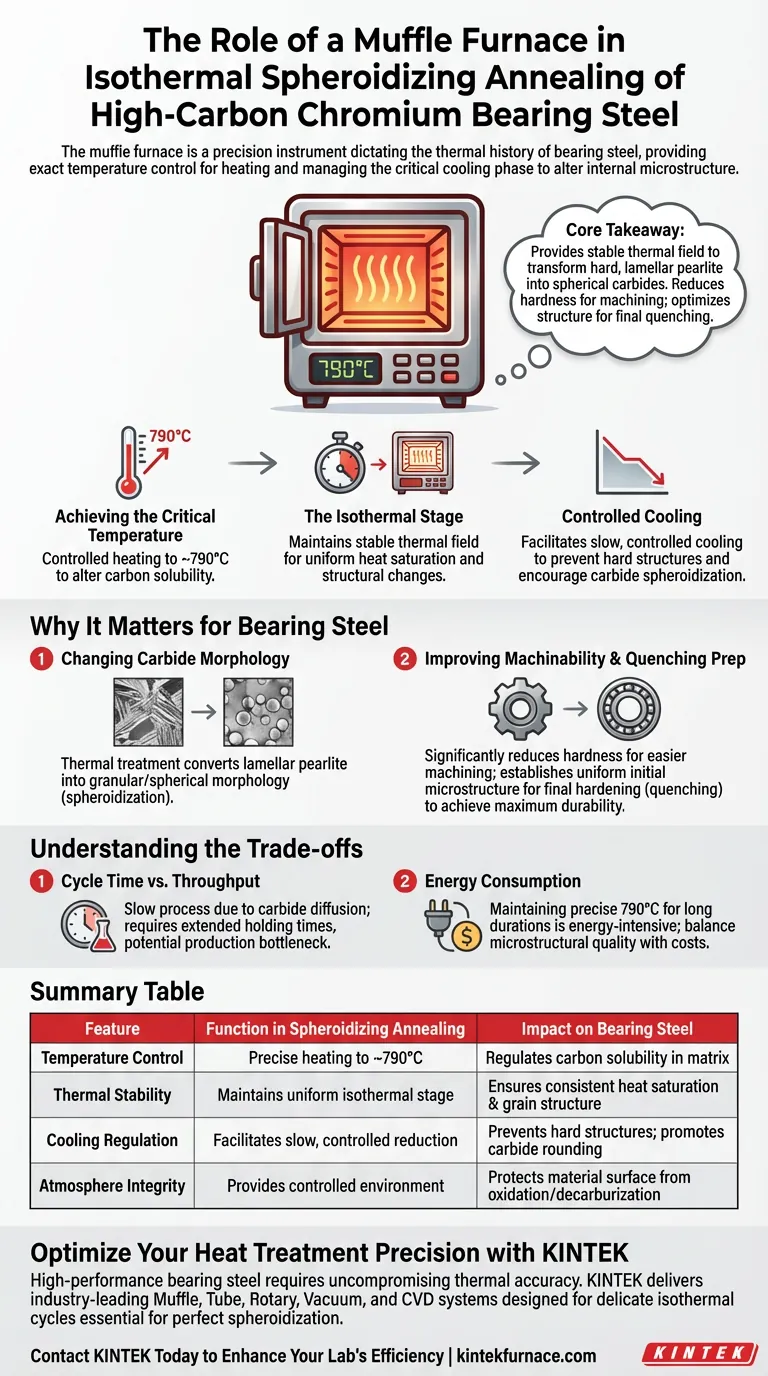

The muffle furnace serves as the precision instrument that dictates the thermal history of high-carbon chromium bearing steel. It provides the exact temperature control needed to heat the material to approximately 790°C and manages the critical cooling phase required to alter the steel's internal microstructure.

Core Takeaway The muffle furnace provides the stable thermal field necessary to transform hard, lamellar pearlite into spherical carbides. This specific structural change reduces hardness for easier machining and optimizes the steel's internal structure for final quenching.

The Mechanics of Microstructural Transformation

Achieving the Critical Temperature

The furnace acts as a controlled environment to heat samples to a specific target, typically around 790°C.

This precise heating is the first step in altering the solubility of carbon within the steel matrix.

The Isothermal Stage

Once the target temperature is reached, the muffle furnace maintains a stable thermal field.

This holding time ensures that the heat saturates the material uniformly, eliminating temperature gradients that could lead to uneven structural changes.

Controlled Cooling

The defining feature of the muffle furnace in this context is its ability to regulate the cooling curve.

Rather than allowing the steel to cool rapidly, the furnace facilitates a slow, controlled reduction in temperature. This specific cooling rate prevents the reformation of hard structures and encourages the desired carbide transformation.

Why This Process Matters for Bearing Steel

Changing Carbide Morphology

The primary chemical goal of this process is spheroidization.

The thermal treatment converts carbides from a plate-like (lamellar) pearlite structure into a granular or spherical morphology.

Improving Machinability

High-carbon chromium bearing steel is naturally extremely hard and difficult to shape.

By transforming the carbides into spheres, the muffle furnace treatment significantly reduces the material's hardness, rendering it softer and much easier to machine into bearing components.

Preparation for Final Quenching

This annealing process is a preparatory step, not the final treatment.

It establishes a proper, uniform initial microstructure. This ensures that when the steel undergoes its final hardening (quenching), it achieves the maximum possible durability and reliability.

Understanding the Trade-offs

Cycle Time vs. Throughput

Isothermal spheroidizing is inherently a slow process due to the physics of carbide diffusion.

The muffle furnace requires extended holding times and slow cooling rates, which can create a production bottleneck compared to faster, less precise heat treatment methods.

Energy Consumption

Maintaining a precise temperature of 790°C for long durations is energy-intensive.

You must balance the strict requirement for microstructural perfection against the operational costs of prolonged furnace cycles.

Optimizing Your Heat Treatment Strategy

To get the most out of the spheroidizing annealing process, align your furnace parameters with your end goals:

- If your primary focus is Machining Efficiency: Prioritize a complete spheroidization cycle to minimize material hardness, which extends the life of your cutting tools.

- If your primary focus is Final Product Durability: Ensure the thermal field is perfectly uniform to prevent inconsistent grain structures that could weaken the bearing after quenching.

Precision in the furnace leads to performance in the field.

Summary Table:

| Feature | Function in Spheroidizing Annealing | Impact on Bearing Steel |

|---|---|---|

| Temperature Control | Precise heating to approx. 790°C | Regulates carbon solubility in the matrix |

| Thermal Stability | Maintains a uniform isothermal holding stage | Ensures consistent heat saturation & grain structure |

| Cooling Regulation | Facilitates slow, controlled temperature reduction | Prevents hard structures; promotes carbide rounding |

| Atmosphere Integrity | Provides a controlled environment | Protects material surface from oxidation/decarburization |

Optimize Your Heat Treatment Precision with KINTEK

High-performance bearing steel requires the uncompromising thermal accuracy that only expert engineering can provide. KINTEK delivers industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed to manage the delicate isothermal cycles essential for perfect spheroidization.

Backed by our elite R&D and manufacturing capabilities, we offer fully customizable laboratory high-temperature furnaces tailored to your specific material requirements. Whether you are aiming to enhance machinability or ensure final product durability, our team is ready to support your unique needs.

Contact KINTEK Today to Enhance Your Lab’s Efficiency

Visual Guide

References

- Wenwen Xu, Chaobin Lai. Effect of Rare Earth Y on Microstructure and Mechanical Properties of High-Carbon Chromium Bearing Steel. DOI: 10.3390/met14040372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is a vacuum muffle furnace used to perform proximate analysis? Precise Biomass Evaluation & Reactivity Analysis

- Why are modern muffle furnaces considered energy-efficient? Discover Key Innovations for Lower Costs

- Why is a muffle furnace critical for Barium Stannate (BSO) nanopowders? Achieve Precise Phase Purity

- What are the advantages and disadvantages of muffle furnaces? Achieve Contaminant-Free Heating for Sensitive Applications

- What process conditions does a muffle furnace provide for aerogel reverse engineering? Unlock Material Reactivation

- What is the function of a high-temperature box furnace in Cu-Ni-P alloy annealing? Optimize Your Cold Rolling Results

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- What steps should be taken after completing an experiment with a muffle furnace? Ensure Safety and Equipment Longevity