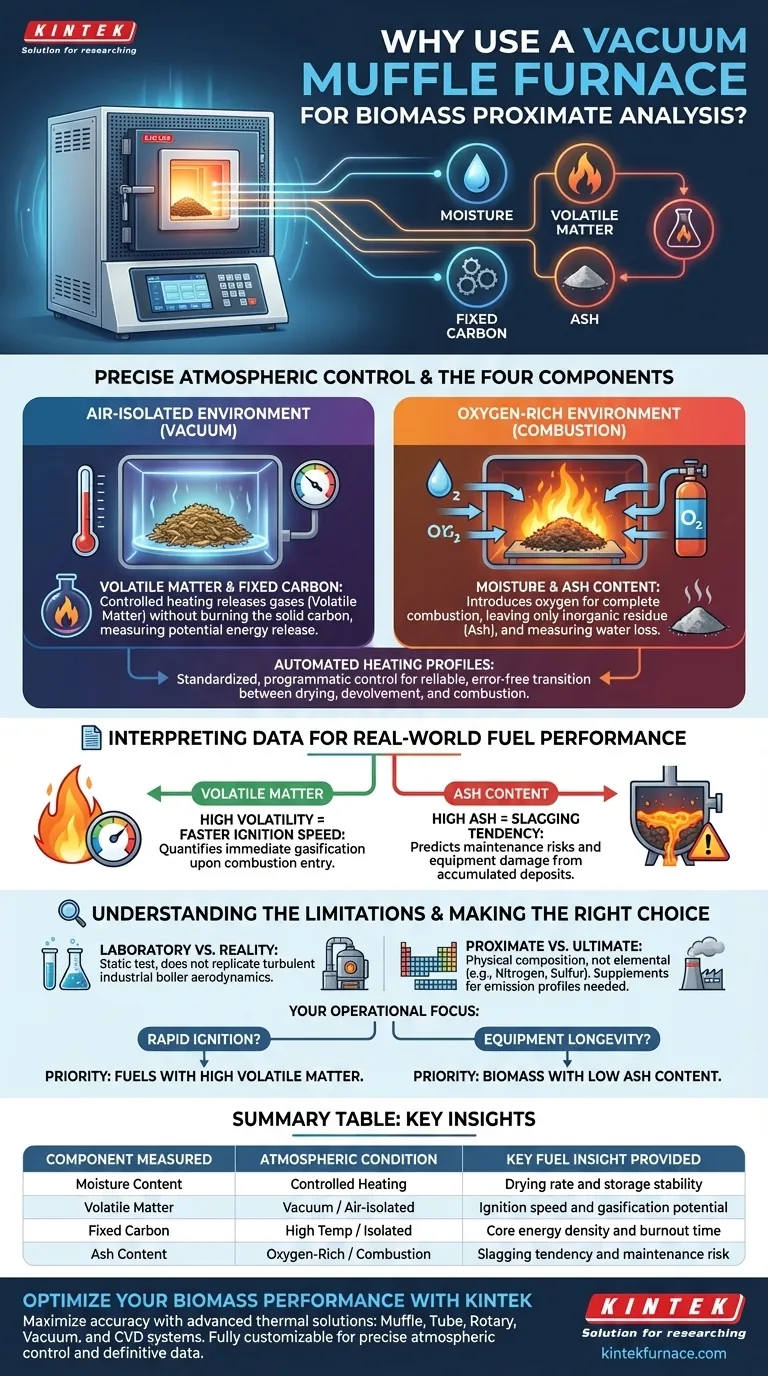

A vacuum muffle furnace is the standard tool for proximate analysis because it allows for precise, programmatic control over the atmospheric conditions surrounding a biomass sample. By switching between an air-isolated environment and an oxygen-rich one, the furnace accurately measures the four critical components of fuel: moisture, volatile matter, fixed carbon, and ash. This controlled thermal processing is the only way to reliably predict the specific combustion behavior of biomass materials.

By isolating volatile matter in a vacuum and measuring ash in oxygen, this equipment provides a definitive profile of a fuel's ignition speed and slagging tendency, transforming raw biomass into predictable energy data.

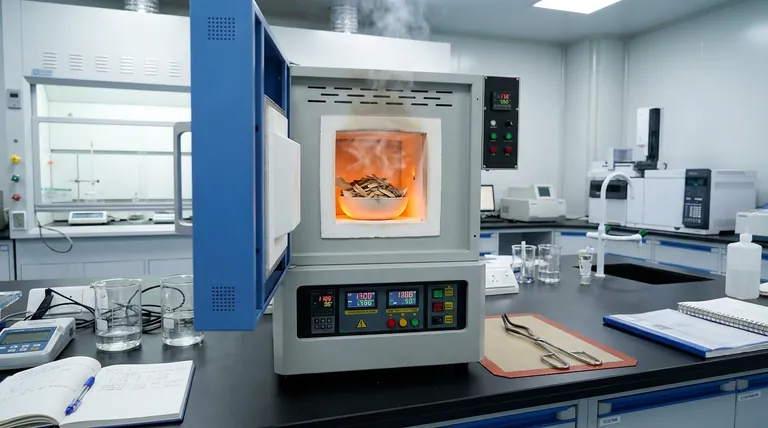

The Mechanics of Proximate Analysis

Precise Atmospheric Control

The core advantage of a vacuum muffle furnace is its ability to manipulate the testing environment. To accurately measure volatile matter, the sample must be heated to release gases without actually burning the solid carbon. This requires a strict environment isolated from air, which the vacuum feature provides.

Conversely, measuring ash content requires the exact opposite condition. The furnace introduces oxygen to facilitate complete combustion, leaving behind only the inorganic residue. This dual capability allows a single instrument to perform opposing chemical processes.

Automated Heating Profiles

Biomass evaluation requires standardized procedures to ensure data is comparable. The furnace uses specific heating programs to ramp temperatures up and hold them for set durations.

This automation eliminates operator error during the transition between drying (moisture loss), devolvement (volatile release), and combustion (ash determination).

Interpreting Data for Fuel Performance

Volatile Matter and Ignition Speed

The data derived from the furnace directly correlates to how the fuel performs in a real-world scenario. The measurement of volatile matter—determined during the air-isolated heating phase—is a key indicator of reactivity.

High volatility typically indicates a faster ignition speed. The furnace quantifies exactly how much of the fuel will gasify and burn immediately upon entering a combustion chamber.

Ash Content and Slagging Tendency

The final stage of the heating program measures the remaining ash content. This is critical for predicting maintenance and operational risks.

High ash levels serve as a warning for slagging tendency, which is the accumulation of melted deposits that can clog boilers. By quantifying the non-combustible material, the furnace helps engineers avoid fuels that might damage generation equipment.

Understanding the Limitations

Laboratory vs. Reality

While a vacuum muffle furnace provides highly accurate chemical data, it remains a static laboratory test. It predicts tendencies based on controlled heating, but it does not perfectly replicate the turbulent aerodynamics or pressure fluctuations of an industrial boiler.

Proximate vs. Ultimate Analysis

It is important to remember that this process yields a proximate analysis (physical composition). It does not provide an ultimate analysis (elemental composition like Nitrogen or Sulfur). Therefore, while it predicts slagging and ignition well, it may not fully predict emission profiles (such as NOx or SOx generation) without supplementary testing.

Making the Right Choice for Your Goal

To maximize the utility of your biomass reactivity evaluation, interpret the furnace data based on your specific operational constraints:

- If your primary focus is rapid ignition: Prioritize fuels that demonstrate high volatile matter percentages during the air-isolated heating phase.

- If your primary focus is equipment longevity: Select biomass sources with low ash content to minimize the risk of slagging and fouling in your boiler.

By leveraging the precise control of a vacuum muffle furnace, you establish a rigorous standard for evaluating and categorizing the energy potential of diverse biomass fuels.

Summary Table:

| Component Measured | Atmospheric Condition | Key Fuel Insight Provided |

|---|---|---|

| Moisture Content | Controlled Heating | Drying rate and storage stability |

| Volatile Matter | Vacuum / Air-Isolated | Ignition speed and gasification potential |

| Fixed Carbon | High Temp / Isolated | Core energy density and burnout time |

| Ash Content | Oxygen-Rich / Combustion | Slagging tendency and maintenance risk |

Optimize Your Biomass Performance with KINTEK

Maximize the accuracy of your fuel reactivity studies with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique laboratory needs. Whether you are analyzing volatile matter or predicting slagging tendencies, our equipment provides the precise atmospheric control required for definitive data.

Ready to elevate your research? Contact us today to discuss your custom furnace requirements!

Visual Guide

References

- Ayrton Monroe, Glauber Cruz. Evaluation of the Bioenergy Potential of Blends (Green Coconut Shells and Fish Scales) as a Feedstock in Thermochemical Processes for Clean Energy Production. DOI: 10.3390/pr12040710

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature muffle furnace control the silver ion release rate? Master Precision Geopolymer Sintering

- How does heat distribution in drying ovens compare to muffle furnaces? Discover Key Differences for Your Lab

- What are the different control types for muffle furnaces? Choose the Right System for Precision and Efficiency

- What role does a high-temperature muffle furnace play in ZnO/CuO preparation? Master Nanocomposite Synthesis

- What are the advantages of energy efficiency and rapid heating/cooling in digital muffle furnaces? Boost Lab Productivity and Cut Costs

- How is temperature controlled in a muffle furnace? Achieve Precision Heating for Your Lab

- How does a high-temperature box furnace contribute to the sintering of doped zirconate ceramics? Achieve 94% Density

- What experimental conditions does an industrial high-temperature muffle furnace provide for thermal stress testing?