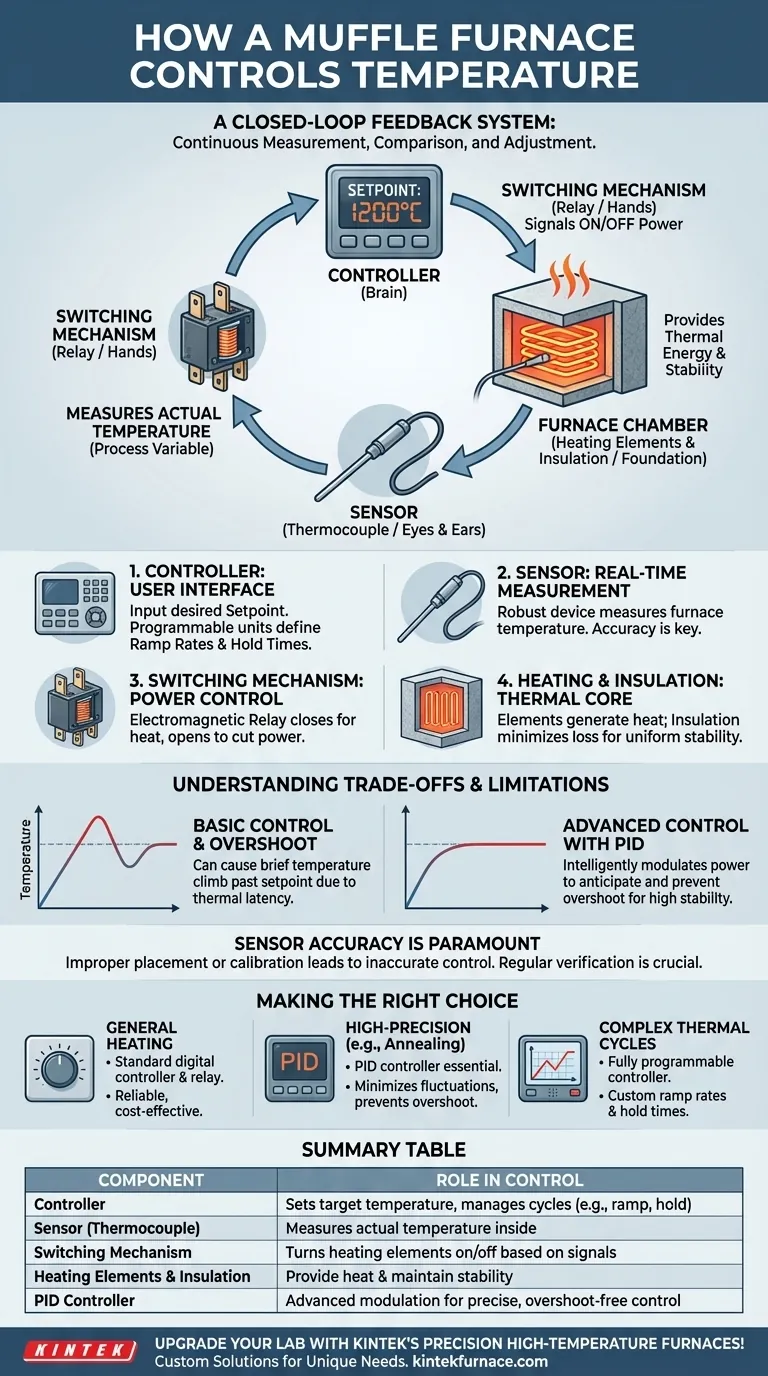

At its core, a muffle furnace controls temperature using a closed-loop feedback system. This system consists of a controller where you set your target temperature, a sensor (typically a thermocouple) that measures the actual temperature inside, and a switching mechanism that turns the heating elements on or off to precisely match your setpoint.

The entire process is a continuous cycle of measurement, comparison, and adjustment. The furnace isn't just "on" or "off"; it is intelligently regulating its power output to hold a specific temperature with remarkable stability.

Deconstructing the Temperature Control System

To truly understand how a muffle furnace achieves its precision, you must look at its key components. Each part plays a distinct and critical role in the temperature regulation process.

The Controller: The Brain of the Operation

The temperature controller is the user interface and the decision-making center. This is where you input the desired temperature, known as the setpoint.

Controllers range from simple manual dials to advanced digital units. Modern programmable controllers allow you to define entire heating cycles, including ramp rates (how fast to heat up), hold times (how long to stay at a temperature), and cooling periods.

The Sensor: The Eyes and Ears

Inside the furnace, a thermocouple acts as the temperature sensor. It is a robust and reliable device that measures the real-time temperature of the furnace chamber.

This measurement, or process variable, is constantly fed back to the controller. The accuracy of the entire system depends heavily on the proper placement and calibration of this thermocouple.

The Switching Mechanism: The Hands

The controller itself does not directly power the heating elements. Instead, it sends a signal to a switching device, typically an electromagnetic relay.

When the controller determines heat is needed, it tells the relay to close, completing the circuit and sending power to the heating elements. When the setpoint is reached, the controller tells the relay to open, cutting the power.

The Heating Elements and Insulation: The Foundation

While not active parts of the control logic, the heating elements and insulation are fundamental. The heating elements provide the thermal energy, while high-performance insulation minimizes heat loss.

Efficient insulation ensures that the temperature remains stable and uniform, making the controller's job easier and improving the overall accuracy and energy efficiency of the furnace.

Understanding the Trade-offs and Limitations

While effective, this control method has inherent characteristics and potential trade-offs that are important to understand for high-precision work.

Basic Control and Temperature Overshoot

A standard controller using a simple on/off relay can sometimes lead to a phenomenon called overshoot. The furnace temperature may briefly climb past the setpoint because of thermal latency—the heating elements are still hot even after the power is cut.

For many applications, this minor fluctuation is perfectly acceptable.

Advanced Control with PID

For processes requiring maximum stability, many furnaces use a PID (Proportional-Integral-Derivative) controller. This is a more sophisticated "brain."

Instead of just switching on or off, a PID controller can intelligently modulate the power to the heating elements. It learns the furnace's behavior to anticipate and prevent overshoot, holding the temperature with exceptional accuracy.

Sensor Accuracy is Paramount

The entire control system is only as good as the information it receives. An improperly placed or uncalibrated thermocouple can report an inaccurate temperature, causing the controller to maintain the wrong setpoint. Regular verification is crucial for sensitive work.

Making the Right Choice for Your Application

Your specific goal determines the level of control you need. By understanding the components, you can choose the right tool for the job.

- If your primary focus is general heating or simple processes: A furnace with a standard digital controller and relay system offers a reliable and cost-effective solution.

- If your primary focus is high-precision applications like annealing or sintering: A furnace equipped with a PID controller is essential to minimize temperature fluctuations and prevent overshoot.

- If your primary focus is complex, multi-stage thermal cycles: A fully programmable controller that allows you to define custom ramp rates and hold times is non-negotiable.

Understanding this control system empowers you to select the right furnace and achieve repeatable, accurate results for your specific application.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| Controller | Sets target temperature and manages heating cycles (e.g., ramp rates, hold times) |

| Sensor (Thermocouple) | Measures actual temperature inside the furnace |

| Switching Mechanism (Relay) | Turns heating elements on/off based on controller signals |

| Heating Elements & Insulation | Provide heat and maintain temperature stability |

| PID Controller | Advanced option for precise modulation to prevent overshoot |

Upgrade your lab with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to achieve superior temperature control and efficiency in your processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination