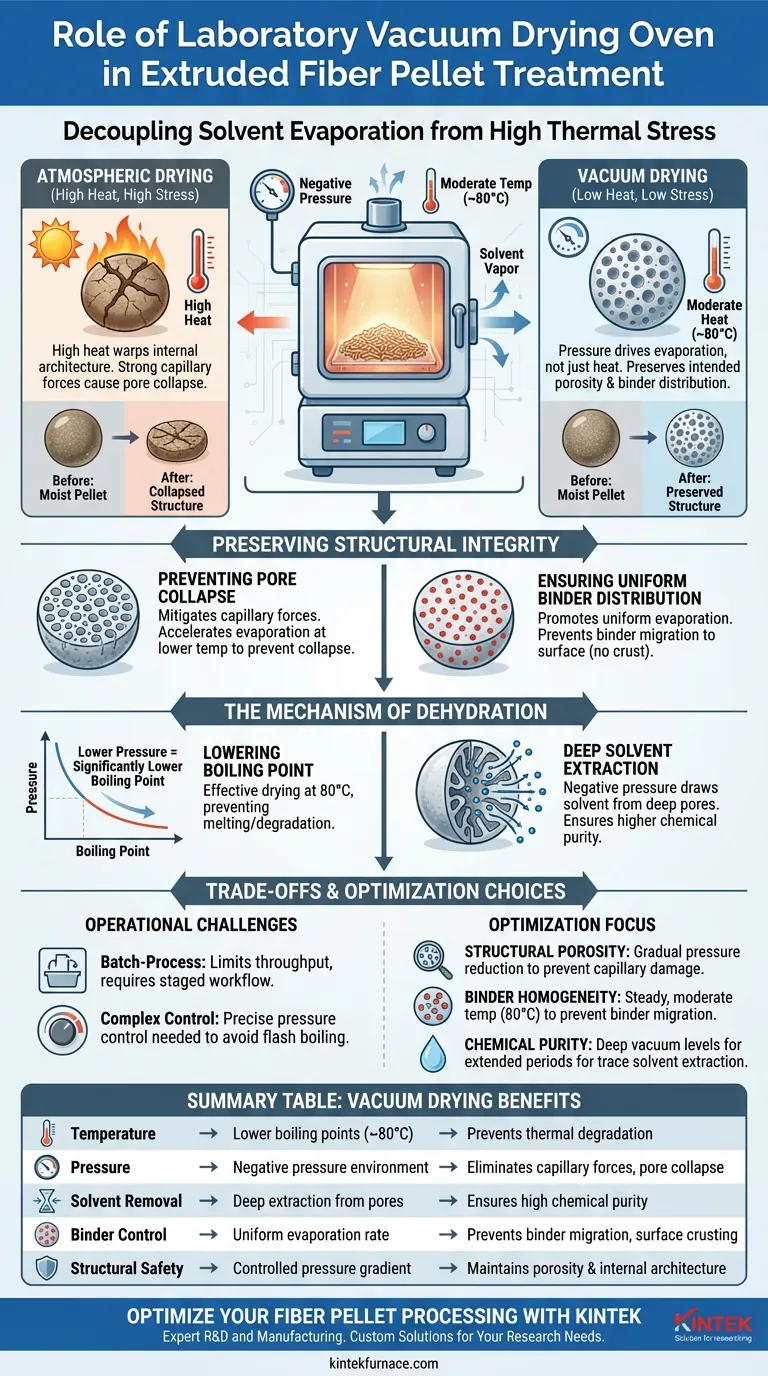

The primary role of a laboratory vacuum drying oven in treating extruded fiber pellets is to decouple solvent evaporation from high thermal stress. By operating under negative pressure at moderate temperatures (typically around 80 °C), the oven significantly lowers the boiling point of residual solvents. This allows for rapid, thorough drying without the material degradation associated with standard atmospheric drying.

Core Takeaway Standard drying methods often rely on high heat, which can warp the internal architecture of delicate materials. Vacuum drying circumvents this by using pressure—not just heat—to drive evaporation, ensuring the fiber pellets retain their intended porosity and binder distribution.

Preserving Structural Integrity

The most critical function of the vacuum oven is protecting the physical architecture of the extruded nanofiber strips.

Preventing Pore Collapse

During atmospheric drying, the capillary forces exerted by evaporating solvents can be strong enough to crush the delicate pores of the fiber.

The vacuum environment mitigates these forces. By accelerating evaporation at lower temperatures, the oven prevents the "pore collapse" that renders the pellet ineffective for applications requiring high surface area.

Ensuring Uniform Binder Distribution

In standard drying scenarios, moisture migration can carry binders to the surface of the pellet, resulting in a hard "crust" and a weak interior.

Vacuum drying promotes a more uniform evaporation rate throughout the pellet volume. This prevents binder migration, ensuring the binder remains evenly distributed to maintain the structural strength of the cylindrical strip.

The Mechanism of Dehydration

Understanding the physics behind the process clarifies why this equipment is essential for chemical purity.

Lowering the Boiling Point

The central principle is the relationship between pressure and boiling points. By reducing the pressure inside the chamber, the solvent's boiling point drops significantly.

This allows the pellets to be dried effectively at 80 °C. At atmospheric pressure, achieving the same level of dryness might require temperatures high enough to melt or degrade the nanofibers.

Deep Solvent Extraction

Extruded pellets often have complex internal geometries where solvents can become trapped.

The negative pressure environment actively draws solvent molecules out from deep within the material's pores. This ensures a higher degree of chemical purity and activation, which is critical if the pellets are precursors for sensitive downstream applications.

Understanding the Trade-offs

While vacuum drying is superior for quality, it introduces specific operational challenges that must be managed.

Throughput Limitations

Unlike continuous conveyor-belt dryers, laboratory vacuum ovens are typically batch-process devices.

This limits the volume of pellets you can process at one time. It requires a carefully staged workflow rather than a continuous production line, which can create bottlenecks in high-throughput environments.

Complexity of Process Control

Vacuum drying is not a "set and forget" method; it requires precise control over the pressure gradient.

If the pressure drops too suddenly, solvents may "flash boil" violently. While the goal is to prevent structural collapse, uncontrolled flash boiling can conversely cause mechanical damage or rupture the pellet structure.

Making the Right Choice for Your Goal

To maximize the utility of a vacuum drying oven for your specific materials, consider these distinct operational focuses:

- If your primary focus is Structural Porosity: Prioritize a gradual reduction in pressure to prevent capillary damage and ensure the pores remain open and uncollapsed.

- If your primary focus is Binder Homogeneity: Maintain a steady, moderate temperature (e.g., 80 °C) to prevent the migration of binding agents to the pellet surface.

- If your primary focus is Chemical Purity: utilize deep vacuum levels for extended periods to extract trace solvents trapped deep within the fiber matrix.

The vacuum drying oven is the definitive tool for converting raw extruded strips into stable, high-performance pellets without compromising their internal architecture.

Summary Table:

| Feature | Vacuum Drying Benefit | Impact on Fiber Pellets |

|---|---|---|

| Temperature | Lower boiling points (~80°C) | Prevents thermal degradation and melting |

| Pressure | Negative pressure environment | Eliminates capillary forces and pore collapse |

| Solvent Removal | Deep extraction from pores | Ensures high chemical purity and activation |

| Binder Control | Uniform evaporation rate | Prevents binder migration and surface crusting |

| Structural Safety | Controlled pressure gradient | Maintains porosity and internal architecture |

Optimize Your Fiber Pellet Processing with KINTEK

Ensure the structural integrity and chemical purity of your materials with high-performance laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of advanced equipment—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique research needs. Whether you are aiming to prevent pore collapse in nanofibers or achieve uniform binder distribution, our vacuum systems provide the precision control you require.

Ready to elevate your lab's drying efficiency? Contact us today to find your custom solution!

Visual Guide

References

- Victor Selmert, Rüdiger‐A. Eichel. Breakthrough analysis of the CO2/CH4 separation on electrospun carbon nanofibers. DOI: 10.1007/s10450-023-00435-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the working principles of a box furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- What are some everyday products manufactured using vacuum furnaces? Discover the Hidden Tech in Your Tools and Devices

- What is vacuum annealing? Achieve Superior Material Purity and Performance

- What are the benefits of using a vacuum furnace? Achieve Superior Purity and Precision in Heat Treatment

- What is the function of a vacuum drying oven in CSAC pretreatment? Preserve Pore Structure & Enhance Modification

- What types of materials and processes are compatible with vacuum furnaces? Achieve Purity and Precision in Heat Treatment

- What are the benefits of using graphite felt in vacuum furnaces? Achieve Superior Thermal Efficiency & Stability

- What is the primary purpose of vacuum sealing raw materials for alpha-Mg3Bi2 crystal growth? Ensure Purity and Safety