In short, vacuum annealing is a high-performance heat treatment that improves a material's properties by heating and cooling it within an oxygen-free vacuum. This process refines the internal structure of metals like steel and other alloys, relieving stress and increasing ductility, all while preventing the surface damage and contamination common in traditional furnaces.

The critical insight is that the vacuum is not just an environment, but a protective shield. By removing reactive gases like oxygen, vacuum annealing ensures that the material's properties are improved without compromising its surface integrity, leading to a cleaner, stronger, and more reliable final product.

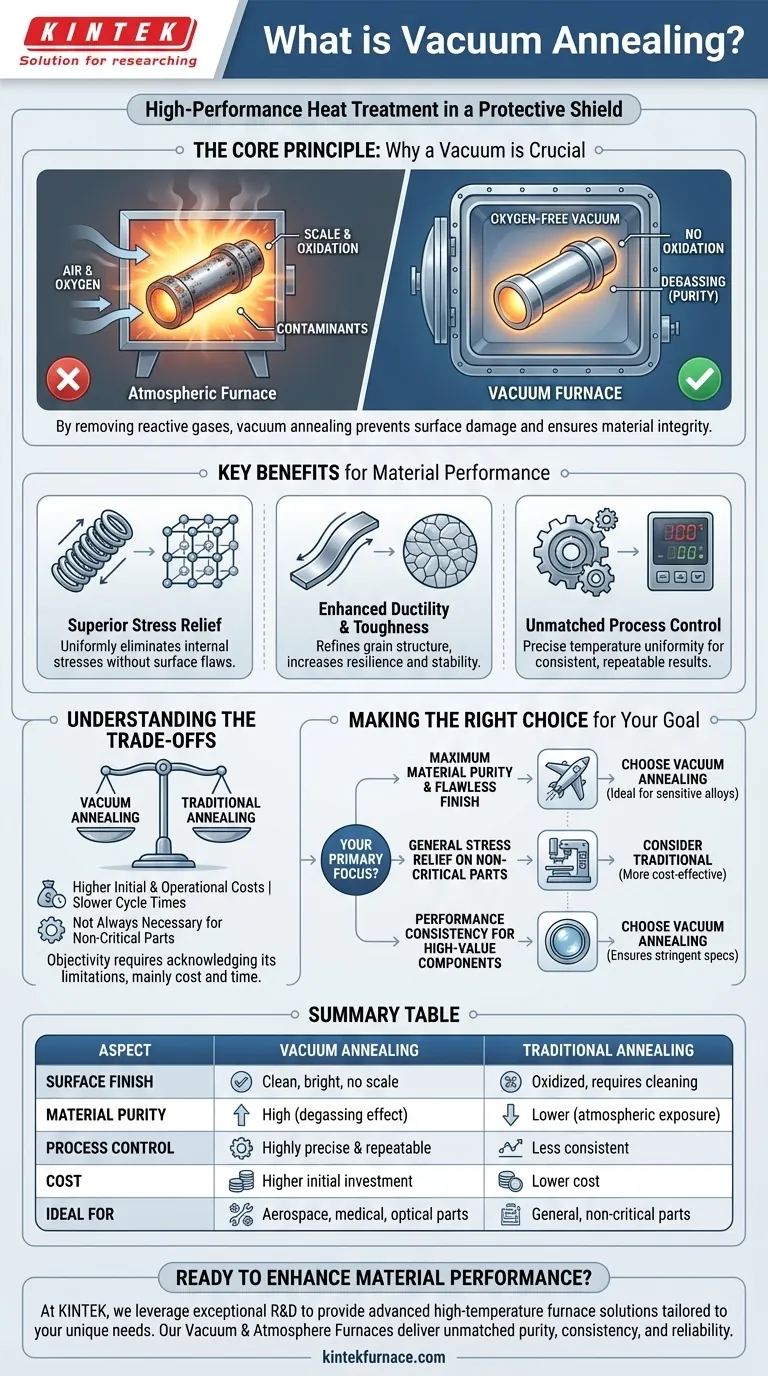

The Core Principle: Why a Vacuum is Crucial

Vacuum annealing operates on a simple but powerful premise: at high temperatures, metal wants to react with its surroundings. A vacuum prevents these unwanted reactions.

Preventing Oxidation and Scale

When metals are heated in the presence of air, they react with oxygen, forming a brittle, discolored oxide layer known as scale. This damages the surface finish and can alter the component's dimensions.

By performing the process in a vacuum, there is virtually no oxygen to react with. The material emerges from the furnace clean and bright, with no scale to remove.

Eliminating Contaminants

The vacuum environment also pulls volatile impurities and contaminants away from the material's surface. This "degassing" effect results in a higher level of material purity, which is critical for many advanced applications.

Key Benefits for Material Performance

Removing the variable of atmospheric reaction allows for predictable and superior improvements to the material itself.

Superior Stress Relief

All manufacturing processes, from stamping to welding, introduce internal stresses into a material. Annealing relieves these stresses by allowing the material's crystal structure to realign.

Vacuum annealing performs this function perfectly, ensuring that stresses are eliminated uniformly without introducing new surface flaws or imperfections from oxidation.

Enhanced Ductility and Toughness

The controlled heating and cooling cycles of vacuum annealing refine the grain structure of the metal. This process increases ductility (the ability to be formed without breaking) and overall toughness.

The result is a material that is more resilient and stable for subsequent processing or for its final application in a demanding environment.

Unmatched Process Control

Modern vacuum furnaces offer exceptionally precise temperature control and uniformity. This ensures that every part in a batch, and every batch over time, receives the exact same treatment, leading to highly consistent and repeatable results.

Understanding the Trade-offs

While powerful, vacuum annealing is not the default choice for every situation. Objectivity requires acknowledging its limitations.

Higher Initial and Operational Costs

Vacuum furnaces represent a significant capital investment compared to conventional atmospheric furnaces. The process itself can also be more expensive due to energy requirements and longer cycle times needed to pump down the chamber.

Slower Cycle Times

Creating and maintaining a stable vacuum adds time to the overall heat treatment process. For high-volume production of non-critical parts, this can impact overall throughput and efficiency.

It Is Not Always Necessary

For applications where surface finish is not a primary concern, or where a subsequent cleaning process is already in place, traditional atmospheric annealing may be a more cost-effective and perfectly adequate solution.

Making the Right Choice for Your Goal

The decision to use vacuum annealing should be driven by the specific requirements of your component and its final application.

- If your primary focus is maximum material purity and a flawless surface finish: Vacuum annealing is the definitive choice, especially for sensitive alloys used in aerospace, medical, or optical fields.

- If your primary focus is general stress relief on non-critical parts: Traditional atmospheric annealing is often the more pragmatic and cost-effective solution.

- If your primary focus is performance consistency for high-value components: The precise control and reliability of vacuum annealing justify the investment to ensure every part meets stringent specifications.

Ultimately, choosing vacuum annealing is an investment in process certainty and final part integrity.

Summary Table:

| Aspect | Vacuum Annealing | Traditional Annealing |

|---|---|---|

| Surface Finish | Clean, bright, no scale | Oxidized, requires cleaning |

| Material Purity | High (degassing effect) | Lower (atmospheric exposure) |

| Process Control | Highly precise and repeatable | Less consistent |

| Cost | Higher initial investment | Lower cost |

| Ideal For | Aerospace, medical, optical parts | General, non-critical parts |

Ready to enhance your material performance with precision vacuum annealing?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your experimental and production requirements.

Whether you're in aerospace, medical, or any field requiring flawless material integrity, KINTEK's vacuum annealing solutions deliver unmatched purity, consistency, and reliability.

Contact us today to discuss how we can optimize your heat treatment process!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement