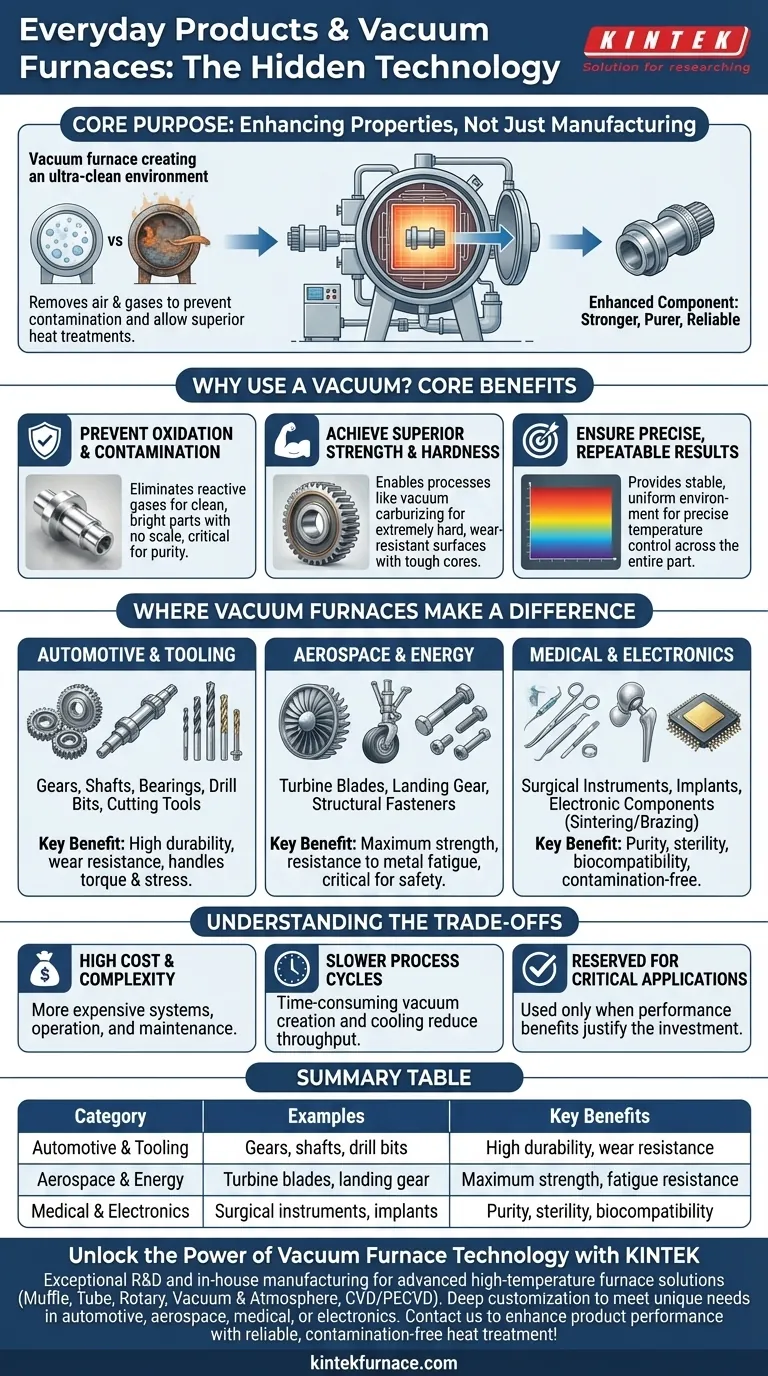

At a glance, you'll find components made in vacuum furnaces in your car's transmission, the drill bits in your toolbox, and even in life-saving medical devices. These furnaces are used to heat-treat metals and other materials in a vacuum, a process that is essential for creating parts that are exceptionally strong, pure, and reliable for high-performance applications.

The core purpose of a vacuum furnace is not to manufacture a product from scratch, but to fundamentally enhance its properties. By removing air and other gases, the furnace creates an ultra-clean environment that prevents contamination and allows for heat treatments that produce superior strength and durability in critical components.

Why Use a Vacuum? The Core Benefits

The decision to use a vacuum furnace comes down to controlling the material's environment at a microscopic level. When metals are heated, they become highly reactive with the gases in the air, especially oxygen. A vacuum eliminates this problem.

To Prevent Oxidation and Contamination

Heating metal in the presence of oxygen causes scale and discoloration, which can compromise the surface finish and integrity of the part. A vacuum removes these reactive gases, resulting in clean, bright parts that require little to no post-processing cleanup.

This purity is critical for applications where even a tiny impurity could cause failure, such as in medical implants or sensitive electronics.

To Achieve Superior Strength and Hardness

Vacuum furnaces enable specialized heat-treatment processes like vacuum carburizing, or case hardening. This process diffuses carbon into the surface of a steel part at high temperatures.

The result is a component with an extremely hard, wear-resistant surface while maintaining a softer, more ductile core. This dual property is what makes gears in a car's transmission tough enough to handle torque without shattering.

To Ensure Precise, Repeatable Results

A vacuum provides an incredibly stable and uniform environment for heating and cooling. This allows for precise temperature control across the entire part, eliminating hot spots or inconsistencies that can create weak points.

This level of control is non-negotiable in industries like aerospace and semiconductor manufacturing, where every component must meet exact specifications every single time.

Where Vacuum Furnaces Make a Difference

While the process is industrial, its results are found in many high-performance products, some of which are surprisingly common.

Automotive and Tooling

The most common examples are gears, shafts, and bearings in automotive transmissions. These parts must withstand immense stress and friction for hundreds of thousands of miles. Vacuum hardening gives them the required durability.

Similarly, high-end drill bits, cutting tools, and industrial dies are hardened in vacuum furnaces to give them a sharp, long-lasting edge capable of cutting other metals.

Aerospace and Energy

Though less "everyday," the aerospace industry relies heavily on vacuum furnaces. Critical components like turbine blades, landing gear components, and structural fasteners are treated this way to ensure maximum strength and resistance to metal fatigue. Failure is not an option in these applications.

Medical and Electronics

The medical field uses vacuum furnaces to manufacture surgical instruments and permanent implants like hip or knee replacements. The vacuum ensures the parts are perfectly clean, sterile, and biocompatible, meaning the body is less likely to reject them.

In electronics, the process is used for sintering (fusing metallic powders) and brazing (joining components) in a contamination-free environment, which is essential for producing reliable semiconductor and electronic components.

Understanding the Trade-offs

Using a vacuum furnace is a strategic choice, not a universal solution. The benefits come with clear trade-offs.

High Cost and Complexity

Vacuum furnaces are significantly more expensive to purchase, operate, and maintain than traditional atmosphere furnaces. The systems required to create and hold a vacuum are complex and energy-intensive.

Slower Process Cycles

Creating a vacuum before the heating cycle begins—and often using inert gas to cool the parts down afterward—takes time. This makes the overall cycle time much longer compared to conventional heat treatment, reducing throughput.

Reserved for Critical Applications

Because of the cost and time, vacuum furnace treatment is reserved for parts where the performance benefits justify the investment. A simple steel bracket or a decorative metal piece would not be manufactured this way, as the added strength and purity are unnecessary.

Making the Right Choice for Your Goal

Understanding the purpose of vacuum heat treatment helps you recognize the hidden engineering in the world around you.

- If your primary focus is extreme durability and wear resistance: Gears, bearings, and cutting tools are prime candidates for vacuum hardening to create a tough, long-lasting surface.

- If your primary focus is absolute purity and cleanliness: Medical implants and electronic components rely on the vacuum process to prevent any contamination that could cause failure or rejection.

- If your primary focus is ultimate strength and reliability: Critical aerospace and energy components are treated in a vacuum to eliminate microscopic weaknesses and ensure they can withstand catastrophic forces.

This invisible industrial process is a key reason why many of our most advanced and reliable technologies function as flawlessly as they do.

Summary Table:

| Product Category | Examples | Key Benefits |

|---|---|---|

| Automotive and Tooling | Gears, shafts, drill bits | High durability, wear resistance |

| Aerospace and Energy | Turbine blades, landing gear | Maximum strength, fatigue resistance |

| Medical and Electronics | Surgical instruments, implants | Purity, sterility, biocompatibility |

Unlock the power of vacuum furnace technology for your lab! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether you're in automotive, aerospace, medical, or electronics. Contact us today to enhance your product performance with reliable, contamination-free heat treatment!

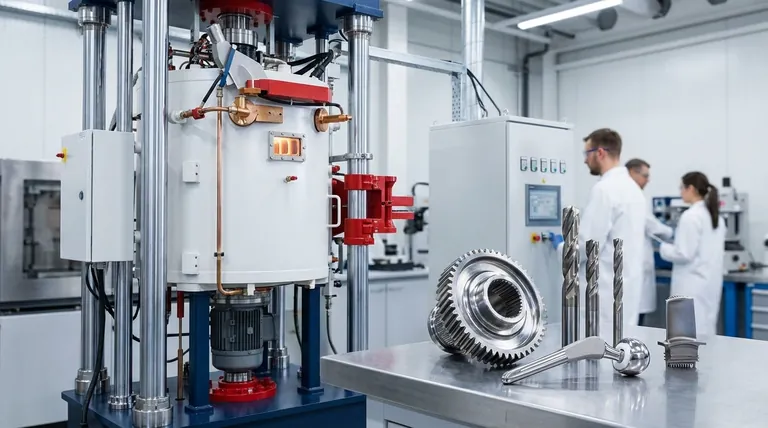

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness