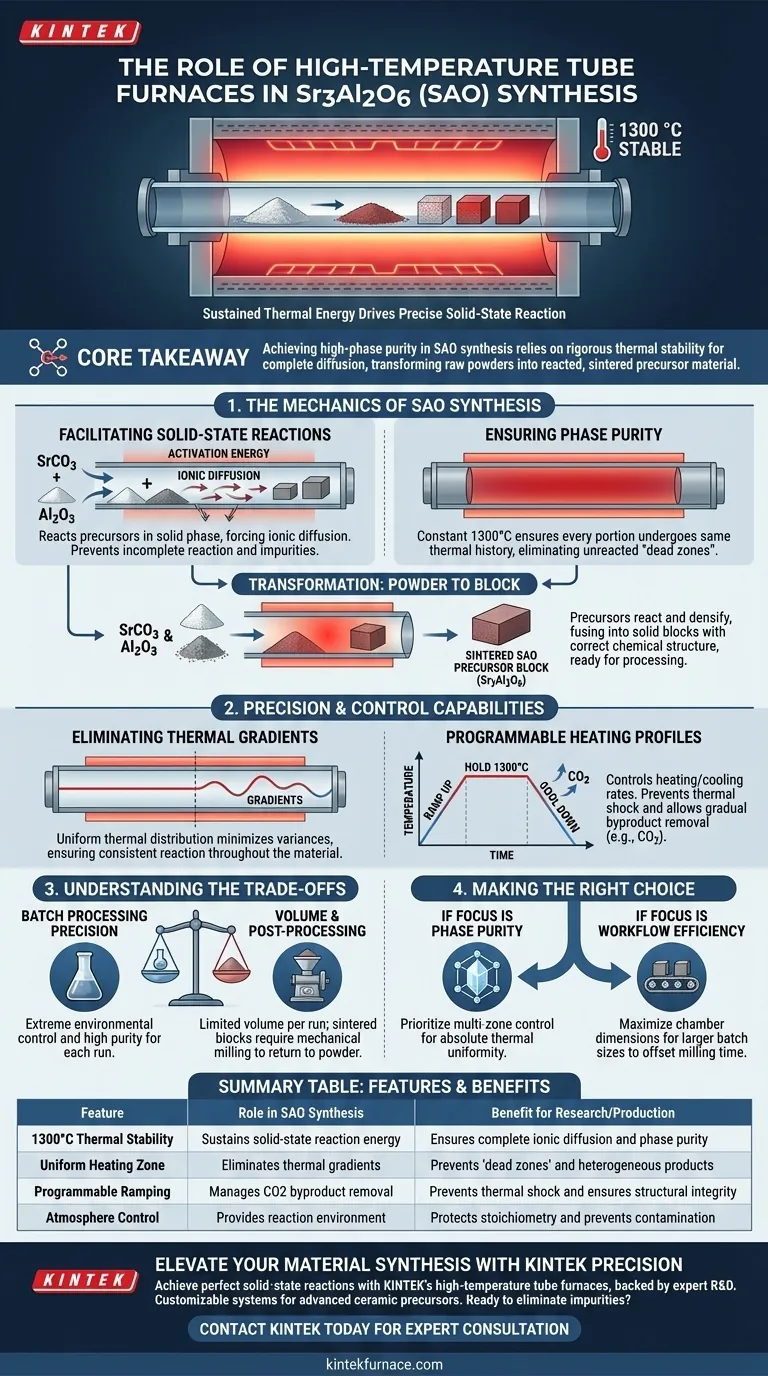

The primary role of a high-temperature tube furnace in synthesizing Sr3Al2O6 (SAO) is to provide the sustained thermal energy required to drive a precise solid-state reaction. Specifically, it maintains a stable environment around 1300 °C, enabling stoichiometric Strontium Carbonate (SrCO3) and Aluminum Oxide (Al2O3) powders to fully react and sinter into high-purity blocks.

Core Takeaway Achieving high-phase purity in SAO synthesis relies not just on reaching high temperatures, but on maintaining them with rigorous stability. The tube furnace facilitates the complete diffusion required for solid-state reactions, transforming loose raw powders into a reacted, sintered precursor material ready for further processing.

The Mechanics of SAO Synthesis

Facilitating Solid-State Reactions

The synthesis of SAO is a solid-state reaction, meaning the precursor materials do not necessarily melt into a liquid but react while remaining in a solid phase.

A tube furnace provides the necessary activation energy to force the diffusion of ions between SrCO3 and Al2O3 particles. Without this sustained heat application, the reaction would remain incomplete, resulting in impurities.

Ensuring Phase Purity

The ultimate goal of using a tube furnace for this application is phase purity.

By maintaining a constant temperature (typically 1300 °C) for an extended period, the furnace ensures that every portion of the powder mixture undergoes the same thermal history. This eliminates unreacted "dead zones" within the material.

Transformation from Powder to Block

Unlike processes that yield a final loose powder, the tube furnace facilitates sintering.

The precursors react and densify, effectively fusing into solid blocks. These blocks are the target raw materials that contain the correct chemical structure of Sr3Al2O6, which can then be processed further.

Precision and Control Capabilities

Eliminating Thermal Gradients

A critical advantage of the tube furnace design is its ability to provide uniform thermal distribution along the heating zone.

In reaction synthesis, temperature gradients (hot or cold spots) can lead to heterogeneous products where some sections are over-sintered and others are under-reacted. The tube furnace minimizes these variances to ensure consistency.

Programmable Heating Profiles

While the primary requirement for SAO is a stable hold at high temperatures, the reaction pathway often requires specific ramp rates.

Modern tube furnaces utilize advanced controllers to manage how fast the sample heats up and cools down. This control prevents thermal shock and allows for the gradual removal of gaseous byproducts (such as CO2 from the carbonate decomposition) before the material densifies completely.

Understanding the Trade-offs

Batch Processing Limitations

Tube furnaces are generally designed for batch processing rather than continuous throughput.

While this allows for extreme precision and environmental control, it limits the volume of SAO precursor that can be synthesized in a single run compared to continuous kilns.

Post-Processing Requirements

Because the tube furnace promotes sintering into blocks, the output is not immediately ready for applications requiring fine powder.

The synthesized SAO blocks typically require a subsequent mechanical milling or grinding step to return them to a powder form, adding a step to the overall production workflow.

Making the Right Choice for Your Goal

When selecting thermal processing equipment for SAO precursors, your decision should depend on your specific purity and volume requirements.

- If your primary focus is Phase Purity: Prioritize a tube furnace with multi-zone control to ensure the absolute highest thermal uniformity at 1300 °C, ensuring no unreacted secondary phases remain.

- If your primary focus is Workflow Efficiency: Ensure the furnace chamber dimensions maximize the batch size of the sintered blocks to offset the time required for the inevitable post-synthesis grinding steps.

The tube furnace is not merely a heater; it is the reaction vessel that dictates the chemical integrity of your final ceramic material.

Summary Table:

| Feature | Role in SAO Synthesis | Benefit for Research/Production |

|---|---|---|

| 1300°C Thermal Stability | Sustains solid-state reaction energy | Ensures complete ionic diffusion and phase purity |

| Uniform Heating Zone | Eliminates thermal gradients | Prevents 'dead zones' and heterogeneous products |

| Programmable Ramping | Manages CO2 byproduct removal | Prevents thermal shock and ensures structural integrity |

| Atmosphere Control | Provides reaction environment | Protects stoichiometry and prevents contamination |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the perfect solid-state reaction for Sr3Al2O6 requires more than just heat; it requires the absolute thermal stability and programmable control found in KINTEK’s high-temperature tube furnaces.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems. Whether you are synthesizing advanced ceramic precursors or developing new semiconductor materials, our lab furnaces are fully customizable to meet your unique stoichiometric and throughput needs.

Ready to eliminate impurities and optimize your sintering workflow?

Contact KINTEK Today for a Expert Consultation

Visual Guide

References

- Benson Kunhung Tsai, Haiyan Wang. CeO<sub>2</sub> Nanostructures Prepared by Selective Water‐Soluble Sr<sub>3</sub>Al<sub>2</sub>O<sub>6</sub>(SAO)‐CeO<sub>2</sub> Vertically Aligned Nanocomposite. DOI: 10.1002/adem.202500530

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is heat transferred to the sample in a multi gradient experimental tube furnace? Master Precise Heat Control

- What is the specific function of a high-temperature tube furnace for MXene-NiCo2Se4? Master the Selenization Process

- What are the key benefits of using a tube furnace for material processing? Achieve Precise Heat Control for Superior Results

- Why is high-purity argon purging necessary for a tube furnace prior to Sb2Se3 synthesis? Ensure Pure Nanowire Growth

- How does a tubular furnace contribute to materials science and engineering research? Unlock Precision in Material Synthesis

- What optional accessories are available for three-zone split tube furnaces? Enhance Control and Efficiency for Your Lab

- What critical conditions do laboratory tube furnaces provide for VLS growth of ZnO nanowires? Master Nanoscale Synthesis

- What is the purpose of using a high-temperature tube furnace for the post-deposition annealing of ITO? Optimize Film Performance