The primary optional accessories for a three-zone split tube furnace are designed to enhance control over the sample's atmosphere, temperature profile, and operational automation. Key additions include quartz or alumina sample boats, water-cooled end caps for thermal management, and sophisticated gas mixing and software control systems for managing complex processes.

The choice of accessories is not about adding features, but about tailoring the furnace to a specific scientific or industrial process. These options transform a general heating device into a precise tool for applications requiring controlled atmospheres and temperature gradients.

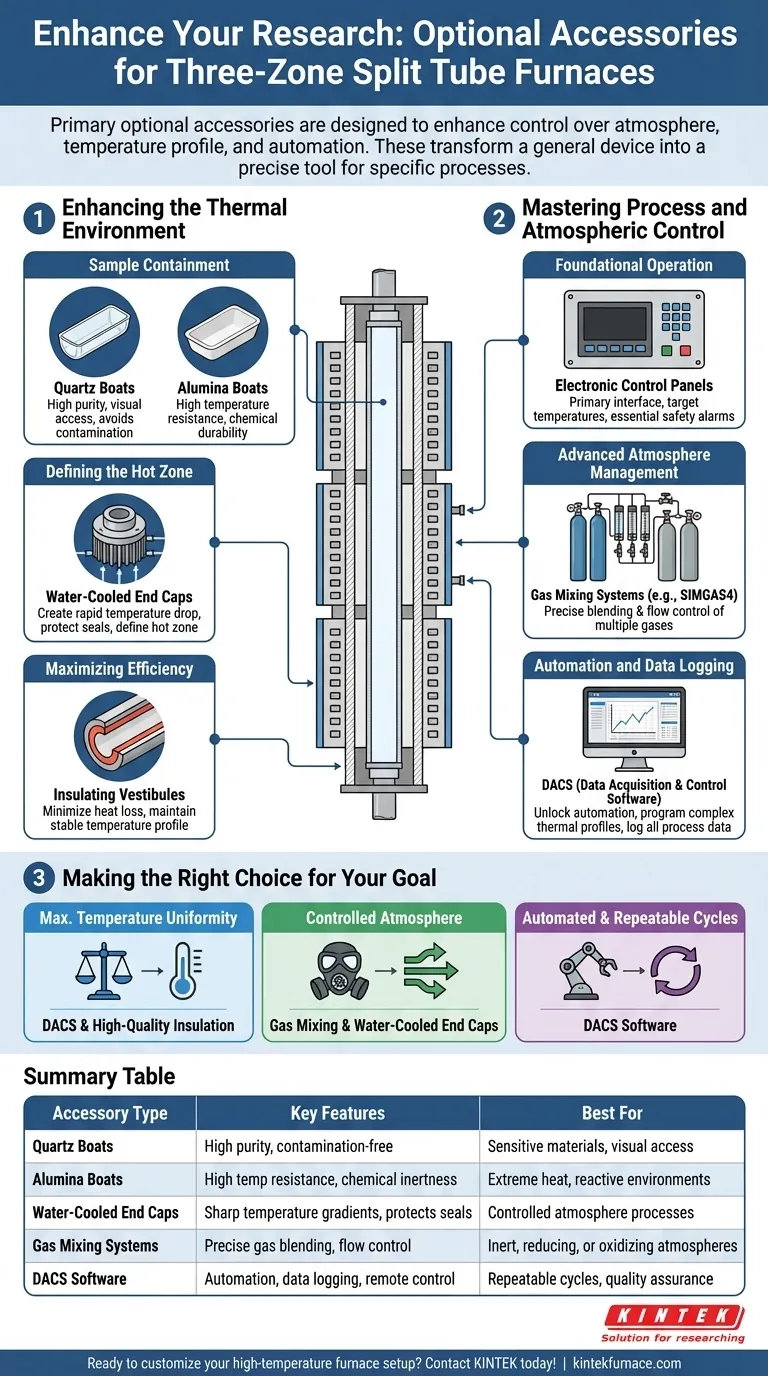

Enhancing the Thermal Environment

The physical accessories you choose directly impact the conditions inside the process tube, from sample handling to the precision of the hot zone.

Sample Containment: Quartz and Alumina Boats

Sample "boats" are simple, trough-like containers that hold your material inside the process tube. The material choice is critical.

Quartz boats are excellent for high-purity applications where avoiding contamination is paramount. They also offer a degree of visual access if your setup allows for it.

Alumina boats are chosen for their ability to withstand higher temperatures and their superior resistance to chemical reactions compared to quartz.

Defining the Hot Zone: Water-Cooled End Caps

Water-cooled end caps are essential for applications requiring a sharply defined temperature gradient.

By circulating coolant, these caps create a rapid temperature drop at the ends of the furnace. This protects rubber O-rings and other gas fittings from heat damage and precisely defines the length of the uniform hot zone.

Maximizing Efficiency: Insulating Vestibules

While often a standard feature, insulating vestibules at the ends of the heating chamber are critical to the furnace's performance.

They work by minimizing heat loss, which helps the furnace maintain a stable and uniform temperature profile across its three zones. This ensures the control system can work effectively without fighting against excessive heat leakage.

Mastering Process and Atmospheric Control

The most powerful accessories are those that give you command over the furnace's operation and the atmosphere surrounding your sample.

Foundational Operation: Electronic Control Panels

Most furnaces come standard with an electronic control panel. This is your primary interface for setting target temperatures for each of the three zones.

These systems typically include essential safety features, such as overheat and thermocouple-break alarms, which are non-negotiable for safe operation.

Advanced Atmosphere Management: Gas Mixing Systems

Three-zone furnaces are frequently used for processes that must occur in a specific atmosphere (e.g., inert, reducing, or oxidizing).

A gas mixing system is an optional module that allows you to precisely blend and control the flow of multiple gases into the process tube. Systems like SIMGAS4 are specialized solutions for this purpose, providing a robust interface for managing complex gas environments.

Automation and Data Logging: DACS

A Data Acquisition and Control Software (DACS) package is the key to unlocking automation and repeatability.

This software allows you to program complex thermal profiles with multiple ramp rates, setpoints, and dwell times. It also enables remote control and, critically, logs all process data for analysis and quality control.

Understanding the Trade-offs

Selecting accessories requires balancing capability against complexity and cost. Not every option is necessary for every application.

Capability vs. Complexity

Adding a gas mixing system or advanced software significantly increases the furnace's capabilities but also introduces new operational variables. Ensure your team has the expertise to manage these more complex setups effectively.

The Purpose of Three Zones

The fundamental advantage of a three-zone furnace is its ability to create either a highly uniform temperature zone or a precise temperature gradient. If your application requires neither, a simpler and more cost-effective single-zone furnace may be a better choice.

Process Demands Dictate Choices

The right accessories are dictated entirely by your process. A system for growing crystals via Chemical Vapor Deposition (CVD) has vastly different requirements (gas mixing, vacuum) than one used for simple annealing in air.

Making the Right Choice for Your Goal

Your selection of accessories should be driven by your primary experimental or production objective.

- If your primary focus is maximum temperature uniformity: Prioritize a furnace with high-quality insulation and a DACS package to precisely tune and balance the three heating zones.

- If your primary focus is controlled atmosphere processing: A gas mixing system and water-cooled end caps are your most critical accessories to manage the environment and protect seals.

- If your primary focus is automated or repeatable cycles: The DACS software option is essential for programming, executing, and logging complex thermal profiles without manual intervention.

Ultimately, viewing these options as tools to achieve a specific outcome will ensure you build a system that is both powerful and perfectly suited to your needs.

Summary Table:

| Accessory Type | Key Features | Best For |

|---|---|---|

| Quartz Boats | High purity, contamination-free | Sensitive materials, visual access |

| Alumina Boats | High temperature resistance, chemical inertness | Extreme heat, reactive environments |

| Water-Cooled End Caps | Sharp temperature gradients, protects seals | Controlled atmosphere processes |

| Gas Mixing Systems | Precise gas blending, flow control | Inert, reducing, or oxidizing atmospheres |

| DACS Software | Automation, data logging, remote control | Repeatable cycles, quality assurance |

Ready to customize your high-temperature furnace setup? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your three-zone split tube furnace is tailored to your unique experimental needs—whether you require precise temperature control, atmosphere management, or automation. Contact us today to discuss how we can enhance your lab's efficiency and achieve your specific goals!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab