At its core, a tubular furnace provides materials scientists and engineers with a highly controlled environment to create and modify materials. By precisely managing temperature, atmosphere, and processing time, these furnaces enable the synthesis of novel materials with specific properties and the optimization of existing ones for advanced applications.

The true value of a tubular furnace isn't just its ability to generate high heat; it is the precision with which it controls the entire thermal process, allowing researchers to dictate material behavior at the atomic and crystalline level.

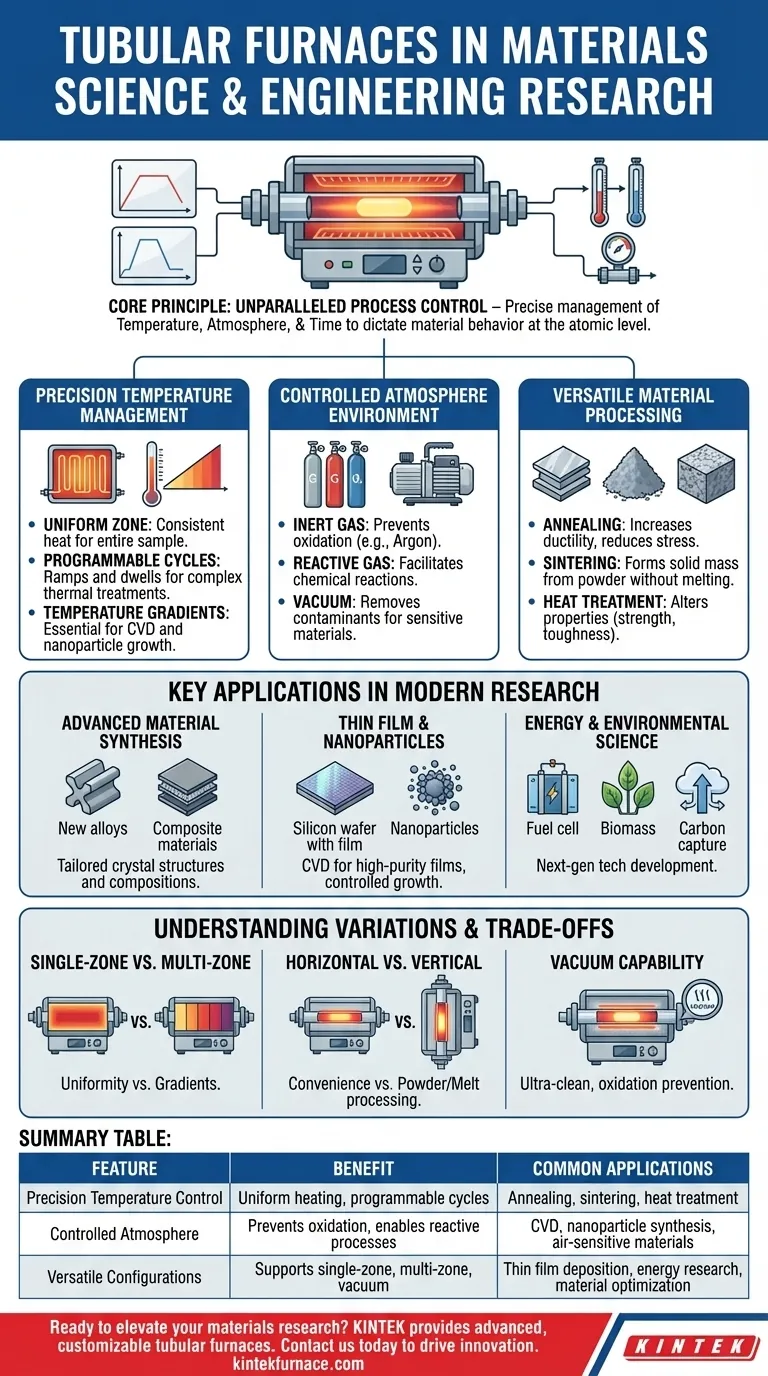

The Core Principle: Unparalleled Process Control

A tubular furnace's contribution to materials science is rooted in its ability to isolate a sample from the outside world and subject it to an exact, repeatable set of conditions. This control is exercised through several key features.

Precision Temperature Management

The furnace's geometry ensures a uniform temperature zone along the length of the process tube. This is critical for ensuring that an entire sample receives the same heat treatment.

Modern furnaces also allow for programmable temperature ramps and dwells, enabling complex thermal cycles. Researchers can also use multi-zone furnaces to create a temperature gradient, which is essential for processes like chemical vapor deposition (CVD) and controlled nanoparticle growth.

Controlled Atmosphere Environment

Many material processes are highly sensitive to oxygen or other elements in the air. A tubular furnace can be sealed and purged with a specific gas to create a controlled atmosphere.

This can be an inert gas like argon to prevent oxidation, a reactive gas to participate in a chemical reaction, or a vacuum to remove atmospheric contaminants entirely. This capability is fundamental for working with sensitive metals, ceramics, and semiconductors.

Versatile Material Processing

This precise control over heat and atmosphere makes the tubular furnace a versatile tool for several foundational materials science processes.

Annealing involves heating and then slowly cooling a material to reduce its hardness and increase its ductility. This removes internal stresses built up during manufacturing.

Sintering is the process of compacting and forming a solid mass of material by heat and pressure without melting it to the point of liquefaction. It is widely used to create ceramic objects and fabricate powdered metals.

Heat treatment is a broad term for processes that alter a material's physical, and sometimes chemical, properties. This is used to achieve desired characteristics like strength, toughness, or corrosion resistance in alloys.

Key Applications in Modern Research

The fundamental capabilities of tubular furnaces directly support innovation across numerous fields.

Advanced Material Synthesis

Researchers use these furnaces to explore new alloys, advanced ceramics, and composite materials. The controlled environment ensures that the resulting material has the intended crystal structure and chemical composition.

Thin Film Deposition and Nanoparticles

In electronics and optics, tubular furnaces are used for chemical vapor deposition (CVD), where gases react on a substrate's surface to form a high-purity thin film. They are also essential for processing nanoparticles, using temperature control to manage uniform growth and morphology.

Energy and Environmental Science

Tubular furnaces are critical tools in developing next-generation technologies. They are used to prepare and test materials for fuel cells, study biomass pyrolysis for renewable energy, and research novel materials for carbon capture and storage.

Understanding the Variations and Trade-offs

Not all tubular furnaces are the same. The specific configuration determines its capabilities and ideal applications.

Single-Zone vs. Multi-Zone

A single-zone furnace is designed to provide one stable, uniform temperature and is perfect for processes like annealing or sintering where consistency is key.

A multi-zone furnace has two or more independently controlled heating zones. This allows the creation of a stable temperature gradient, which is necessary for advanced synthesis techniques like CVD.

Horizontal vs. Vertical Orientation

Most lab furnaces are horizontal, which is convenient for loading and observing samples. A vertical orientation can be advantageous for processing powders, preventing sample contamination from the tube walls, or working with materials that melt.

The Role of Vacuum Capability

Adding vacuum capability significantly expands a furnace's utility. A vacuum furnace allows for processing in an ultra-clean environment, which is essential for preventing oxidation in highly reactive metals or for studying material behavior without atmospheric interference.

Making the Right Choice for Your Goal

To leverage a tubular furnace effectively, you must match the process to your desired material outcome.

- If your primary focus is improving material toughness or reducing brittleness: Use an annealing process with a controlled, slow cooling rate.

- If your primary focus is creating a solid, dense object from a powder: Use a sintering process at a high temperature below the material's melting point.

- If your primary focus is synthesizing new thin films or nanoparticles: Use a multi-zone furnace to create a temperature gradient for a CVD or crystal growth process.

- If your primary focus is processing air-sensitive materials: Ensure your furnace is configured for vacuum operation or can be purged with an inert gas like argon.

Ultimately, the tubular furnace is a foundational instrument that empowers researchers to move from theoretical material design to tangible, physical innovation.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Precision Temperature Control | Ensures uniform heating and programmable cycles | Annealing, sintering, heat treatment |

| Controlled Atmosphere | Prevents oxidation and enables reactive processes | CVD, nanoparticle synthesis, air-sensitive materials |

| Versatile Configurations | Supports single-zone, multi-zone, and vacuum setups | Thin film deposition, energy research, material optimization |

Ready to elevate your materials research with tailored high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced tubular furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're synthesizing novel materials or optimizing processes. Contact us today to discuss how our expertise can drive your innovations forward!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing