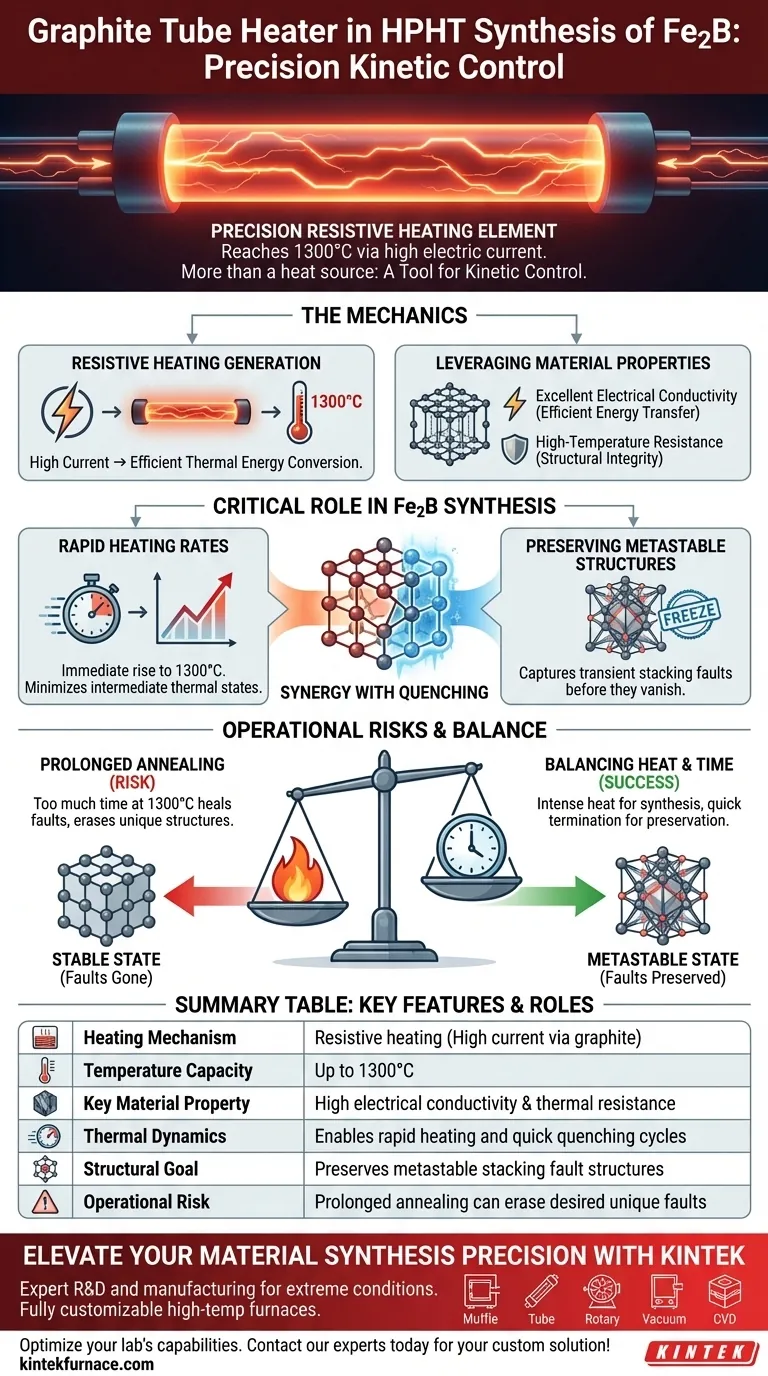

In the high-pressure high-temperature (HPHT) synthesis of Fe2B, the graphite tube serves as a precision resistive heating element. It functions by passing high electric current through the material to generate temperatures reaching 1300°C. Due to its excellent electrical conductivity and thermal resistance, the graphite tube facilitates the rapid heating necessary to create specific material conditions without degrading under the extreme environment.

The graphite tube is not merely a heat source; it is a tool for kinetic control. Its ability to heat samples rapidly—combined with subsequent rapid quenching—is the defining factor that allows researchers to capture and preserve metastable stacking fault structures in Fe2B that would otherwise vanish.

The Mechanics of Graphite Heating

Resistive Heating Generation

The fundamental role of the graphite tube is to act as a resistive load within the high-pressure assembly.

By running a high electric current through the tube, electrical energy is efficiently converted into thermal energy. This mechanism allows the system to reach an operational temperature of 1300°C.

Leveraging Material Properties

Graphite is the material of choice for this application due to two specific physical properties.

First, its excellent electrical conductivity ensures efficient energy transfer from the power source to the sample. Second, its high-temperature resistance allows it to maintain structural integrity while generating extreme heat, ensuring the synthesis environment remains stable.

Critical Role in Synthesizing Fe2B

Achieving Rapid Heating Rates

For the synthesis of Fe2B in this specific context, the speed of temperature increase is paramount.

The graphite tube is capable of rapid heating, bringing the sample to the target 1300°C almost immediately. This minimizes the time the sample spends in intermediate thermal states.

Preserving Metastable Structures

The most sophisticated role of the graphite heater involves the preservation of delicate structural features.

The synthesis aims to capture metastable stacking fault structures within the Fe2B. These structures are transient; if the material is exposed to high temperatures for too long (prolonged annealing), these unique faults will disappear as the material relaxes into a more stable state.

Synergy with Quenching

The graphite tube's performance is inextricably linked to the cooling phase.

The system relies on the combination of rapid heating (via the graphite tube) and rapid quenching (after pressure release). This thermal cycle effectively "freezes" the metastable structures in place before they can be erased by thermal equilibrium.

Operational Considerations and Risks

The Danger of Prolonged Annealing

While the graphite tube is powerful, the thermal profile it generates must be managed with extreme precision.

The primary risk in this synthesis is prolonged high-temperature annealing. If the heater maintains the temperature of 1300°C for too long, the energy provided will cause the desired stacking faults to heal and disappear.

Balancing Heat and Time

Success depends on minimizing the duration of heat exposure.

The graphite tube must heat the sample intensely enough to synthesize the Fe2B phase, but the process must be terminated quickly to retain the metastable characteristics.

Making the Right Choice for Your Goal

To successfully synthesize Fe2B with specific structural characteristics, you must control the thermal profile generated by the graphite assembly.

- If your primary focus is capturing metastable structures: Prioritize maximum heating rates and ensure the heating cycle is immediately followed by rapid quenching to prevent annealing.

- If your primary focus is standardizing synthesis conditions: Monitor the electric current consistency to ensure the target 1300°C is reached without overshooting, which could inadvertently anneal the sample.

Ultimately, the graphite tube acts as a precise thermal switch, enabling the existence of unique Fe2B structures that are otherwise impossible to retain.

Summary Table:

| Feature | Role in HPHT Fe2B Synthesis |

|---|---|

| Heating Mechanism | Resistive heating (High current via graphite) |

| Temperature Capacity | Reaches up to 1300°C |

| Key Material Property | High electrical conductivity & thermal resistance |

| Thermal Dynamics | Enables rapid heating and quick quenching cycles |

| Structural Goal | Preserves metastable stacking fault structures |

| Operational Risk | Prolonged annealing can erase desired unique faults |

Elevate Your Material Synthesis Precision with KINTEK

Achieving the perfect thermal profile for HPHT synthesis requires equipment designed for extreme conditions. Backed by expert R&D and manufacturing, KINTEK offers a wide range of high-performance solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Whether you are synthesizing Fe2B or developing next-generation ceramics, our lab high-temp furnaces are fully customizable to meet your unique research needs. Ensure rapid heating and precise quenching to capture every metastable structure.

Ready to optimize your lab's high-temperature capabilities? Contact our experts today to find your custom solution!

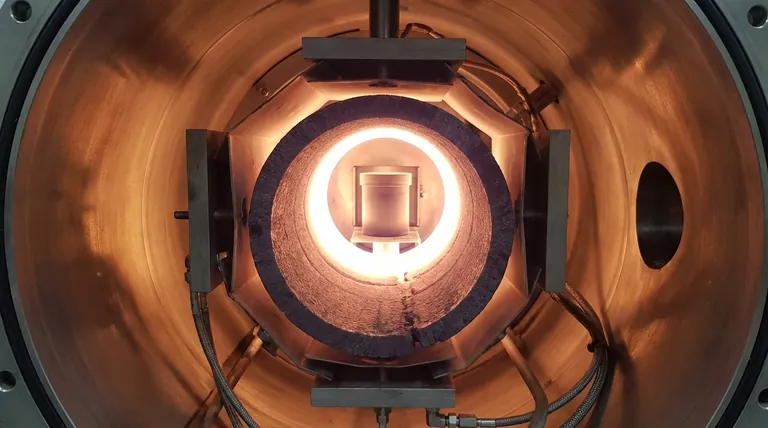

Visual Guide

References

- Haoyu Li, Qiang Tao. Unveiling the Stacking Faults in Fe2B Induces a High-Performance Oxygen Evolution Reaction. DOI: 10.3390/catal15010089

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What are some common applications of tubular furnaces? Unlock Precision in High-Temperature Processing

- How do tube furnaces achieve precise temperature control? Unlock Reliable High-Temp Processing

- How is an industrial tube furnace utilized to evaluate the thermal stability of modified diamond powders?

- Why is a secondary high-temperature activation process in a tube furnace necessary? Converting Biochar into CBAC

- Why are horizontal tube furnaces ideal for small scale materials tests? Unlock Precision and Efficiency in Your Lab

- Why is a high-precision programmable tube furnace required for N-doped TiO2@C composites? Expert Thermal Solutions

- What advantages do three-zone furnaces offer? Achieve Superior Temperature Control and Efficiency

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution