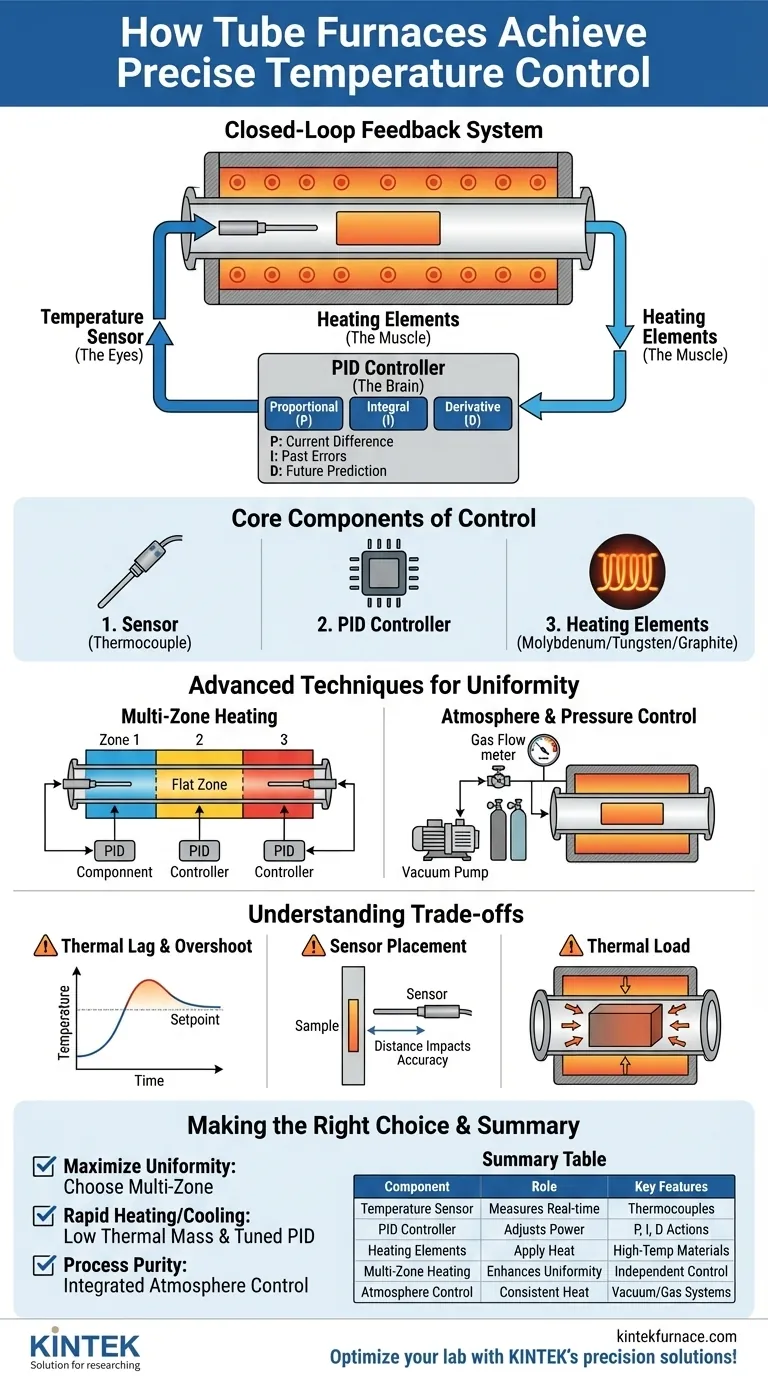

At its core, a modern tube furnace achieves precise temperature control through a sophisticated closed-loop feedback system. This system continuously measures the internal temperature with a sensor, compares it to the desired setpoint, and uses an intelligent controller to minutely adjust the power delivered to the electric heating elements, ensuring stability and uniformity.

The precision of a tube furnace isn't the result of a single component, but rather the constant, high-speed communication between its three key parts: a temperature sensor (the eyes), a PID controller (the brain), and the heating elements (the muscle).

The Core Components of Temperature Control

To understand how precision is achieved, we must first look at the individual components working in concert. Each part plays a distinct and critical role in the feedback loop.

The Sensor: The Eyes of the System

A temperature sensor, most commonly a thermocouple, is placed inside or very near the furnace tube. Its sole job is to provide an accurate, real-time measurement of the furnace's internal temperature.

This constant stream of data is the "feedback" in the control loop, telling the system what is actually happening versus what is supposed to be happening.

The Controller: The Brain of the Operation

The temperature controller is the intelligent center of the system. Modern furnaces almost universally use a PID (Proportional-Integral-Derivative) controller.

This controller receives the temperature reading from the sensor and compares it to your target setpoint. It then calculates the precise amount of power the heating elements need.

- Proportional (P): Reacts to the current difference between the setpoint and the actual temperature. The larger the error, the more power it applies.

- Integral (I): Corrects for past errors. It looks at the accumulated error over time to eliminate the small, steady-state inaccuracies that the proportional term might miss.

- Derivative (D): Predicts future errors by analyzing the rate of temperature change, preventing the system from overshooting the setpoint.

The Heating Elements: The Muscle

Modern furnaces use high-temperature electric heating elements made from materials like molybdenum, tungsten, or graphite. These are far more controllable than older combustion methods.

The PID controller directly manages the electrical current flowing to these elements. By making thousands of micro-adjustments per minute, it can deliver the exact amount of energy needed to maintain a stable temperature, often with a uniformity of ±1°C.

Advanced Techniques for Enhanced Uniformity

For applications demanding the highest level of precision, standard control is enhanced with more advanced system designs.

Multi-Zone Heating

Instead of one large heating element, some furnaces are built with multiple, independently controlled heating zones arranged along the length of the tube.

Each zone has its own sensor and PID control loop. This allows the system to compensate for heat loss at the ends of the tube, creating an exceptionally uniform flat zone in the center or even establishing a precise temperature gradient for specialized processes.

Furnace Atmosphere and Pressure

Control systems also integrate with vacuum pumps and gas flow controllers. While not directly controlling temperature, maintaining a specific vacuum level or inert gas atmosphere is crucial.

This prevents unwanted chemical reactions and ensures that heat transfer within the tube is consistent and predictable, which is essential for achieving reliable results in sensitive applications like aerospace component brazing or medical implant sintering.

Understanding the Trade-offs and Limitations

Even the most advanced system is subject to physical constraints. Understanding these is key to achieving truly repeatable results.

Thermal Lag and Overshoot

There is an inherent delay between the heating element changing temperature and your sample reaching that same temperature. This is thermal lag.

A poorly tuned PID controller can overcompensate for this lag, causing the temperature to rise past the setpoint (overshoot) before settling down. Proper tuning is critical for both speed and stability.

The Importance of Sensor Placement

The controller only knows the temperature at the precise location of its sensor. If the sensor is far from your sample, the temperature your sample experiences may be different from the temperature on the display.

For critical processes, placing the thermocouple as close to the sample as possible is essential for true process accuracy.

Impact of Thermal Load

A large, dense sample (a high thermal load) will absorb a significant amount of energy and can create cold spots within the furnace. The control system must work harder to supply enough energy to heat the load uniformly while maintaining the setpoint.

Making the Right Choice for Your Process

The ideal furnace configuration depends entirely on your primary objective.

- If your primary focus is maximum temperature uniformity: Choose a furnace with at least three, and preferably more, independently controlled heating zones.

- If your primary focus is rapid heating and cooling: Look for a system with low thermal mass insulation and a well-tuned PID controller designed for aggressive ramp rates.

- If your primary focus is process purity and repeatability: Prioritize an integrated system with precise atmosphere control (vacuum or gas) in addition to multi-zone temperature control.

Ultimately, understanding these control principles empowers you to select the right tool and design a process that delivers accurate, reliable, and high-quality results.

Summary Table:

| Component | Role in Temperature Control | Key Features |

|---|---|---|

| Temperature Sensor | Measures real-time temperature | Uses thermocouples for feedback |

| PID Controller | Adjusts power based on error | Proportional, Integral, Derivative actions |

| Heating Elements | Apply heat as directed | Made from molybdenum, tungsten, or graphite |

| Multi-Zone Heating | Enhances uniformity | Independent control for flat zones or gradients |

| Atmosphere Control | Maintains consistent heat transfer | Integrates vacuum and gas systems |

Optimize your lab's high-temperature processes with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced tube furnaces, muffle furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems tailored for aerospace, medical, and research applications. Our strong deep customization capability ensures your unique experimental requirements are met with reliability and efficiency. Contact us today to discuss how our high-temperature furnace solutions can enhance your results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents