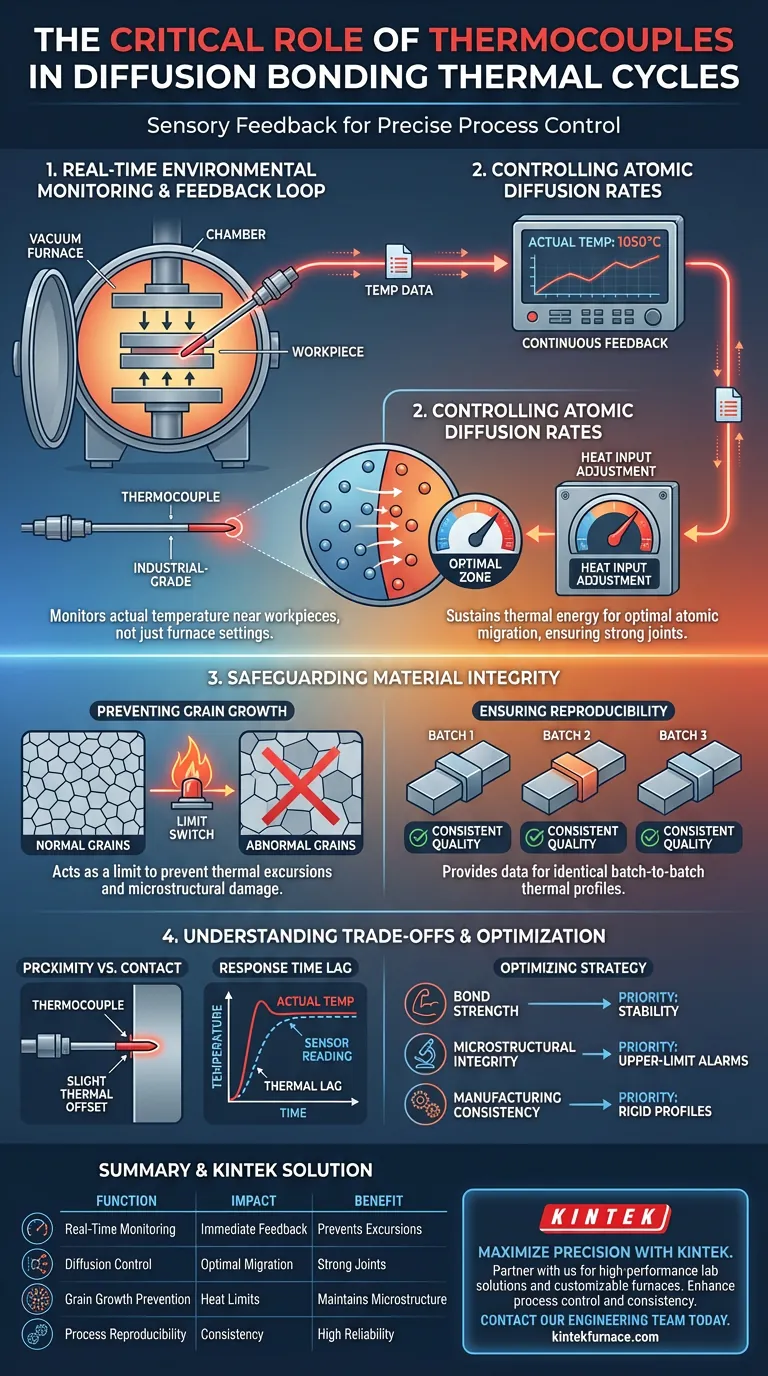

Industrial-grade thermocouples serve as the critical sensory feedback loop during the diffusion bonding process. Fixed in close proximity to the workpieces, they monitor the actual temperature in real-time throughout both the active bonding phase and the subsequent annealing cycles to ensure the thermal environment matches the precise requirements of the joining process.

The success of diffusion bonding relies on managing the energy required for atoms to migrate across an interface. Thermocouples provide the data necessary to control this atomic diffusion rate while strictly limiting the heat to prevent structural degradation.

The Mechanics of Process Control

To understand the necessity of these sensors, one must look at how temperature dictates the physical properties of the bond.

Real-Time Environmental Monitoring

The primary function of the thermocouple is to provide continuous, immediate feedback regarding the thermal state of the chamber.

Because they are fixed near the samples, they measure the environment the part actually experiences, rather than just the theoretical setting of the furnace heating elements.

Controlling Atomic Diffusion Rates

Diffusion bonding is driven by the migration of atoms across the interface of two surfaces.

This atomic movement is highly sensitive to thermal energy. The thermocouples ensure the temperature remains high enough to sustain the optimal diffusion rate necessary for a strong, void-free joint.

Safeguarding Material Integrity

Beyond ensuring the bond happens, thermocouples play a defensive role in protecting the base materials.

Preventing Abnormal Grain Growth

Excessive heat is the enemy of material microstructure.

If the temperature overshoots the target window, the material grains can grow uncontrollably, weakening the final part. Thermocouples act as a limit switch, preventing these thermal excursions that lead to abnormal grain growth.

Ensuring Process Reproducibility

For industrial applications, a one-off success is insufficient; the process must be repeatable.

By rigorously monitoring the thermal profile of both the bonding and annealing stages, thermocouples provide the data needed to guarantee batch-to-batch consistency.

Understanding the Trade-offs

While thermocouples are essential, relying on them requires an understanding of their physical limitations in an industrial setting.

Proximity vs. Contact

The reference notes that thermocouples are fixed near the samples.

This means there may be a slight thermal offset between the sensor reading and the actual core temperature of the part, particularly in large vacuum furnaces.

Response Time Lag

Industrial-grade sensors are robust, but they can have a slower response time than delicate laboratory sensors.

Rapid temperature spikes might occur slightly faster than the sensor registers them, requiring control systems that account for slight thermal lag.

Optimizing Your Thermal Strategy

To maximize the effectiveness of your diffusion bonding process, consider how you utilize temperature data based on your specific objectives.

- If your primary focus is Bond Strength: Prioritize temperature stability to maintain a constant atomic diffusion rate without interruption.

- If your primary focus is Microstructural Integrity: Set strict upper-limit alarms based on thermocouple feedback to strictly prevent grain growth.

- If your primary focus is Manufacturing Consistency: Use the thermocouple data to create rigid thermal profiles that ensure every run is identical to the last.

Precise thermal monitoring transforms diffusion bonding from a theoretical concept into a reliable, repeatable manufacturing reality.

Summary Table:

| Function | Impact on Bonding Process | Benefit to Material Integrity |

|---|---|---|

| Real-Time Monitoring | Immediate feedback on chamber environment | Prevents thermal excursions |

| Diffusion Control | Maintains optimal atomic migration rates | Ensures strong, void-free joints |

| Grain Growth Prevention | Limits heat to stay within specific windows | Maintains original microstructure |

| Process Reproducibility | Guarantees batch-to-batch thermal consistency | High manufacturing reliability |

Maximize Your Precision with KINTEK

Achieving the perfect diffusion bond requires uncompromising thermal accuracy. KINTEK provides the high-performance laboratory solutions you need to master complex thermal cycles. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to your unique industrial requirements.

Don't let thermal lag or grain growth compromise your materials. Partner with KINTEK to enhance your process control and manufacturing consistency.

Contact Our Engineering Team Today

Visual Guide

References

- José Rodolpho de Oliveira Leo, Michael E. Fitzpatrick. Development of a Diffusion Bonding Route for Joining Oxide-Dispersion-Strengthened (ODS) Steels for Nuclear Applications. DOI: 10.1007/s11661-023-07288-2

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What material are silicon carbide heating elements made from? Discover High-Temp Solutions

- What is the primary function of electric heating elements? Convert Electricity to Reliable Heat Efficiently

- What materials are used in high-temperature furnace heating elements? Discover the Best Choices for Your Lab

- What is the role of K-type thermocouples in monitoring photocatalytic reactions? Key to Precise Thermal Data

- What are the key properties of silicon carbide that make it suitable for heating elements? Discover Its High-Temp Durability and Efficiency

- What is the maximum operating temperature of SIC heating elements? Achieve Robust High-Temp Performance

- Where are H Type Silicon Carbide Heating Elements commonly used? Ideal for High-Temp Cycling in Glass, Electronics, and Chemicals

- In what heat treatment processes are alumina ceramic tubes commonly used? Essential for High-Temp Metal, Ceramic, and Glass Applications