At its core, a silicon carbide heating element is made from silicon carbide (SiC), an advanced ceramic compound. Unlike common metallic heating elements, SiC is formed from high-purity silicon carbide grains that are bonded together at extremely high temperatures, creating a dense, rigid, and self-supporting structure capable of operating where many metals would fail.

The name "silicon carbide heating element" tells you the what, but not the why. The critical insight is that SiC is chosen over more common metal alloys for its superior performance at very high temperatures (above 1300°C) in air, despite being more brittle and complex to manage.

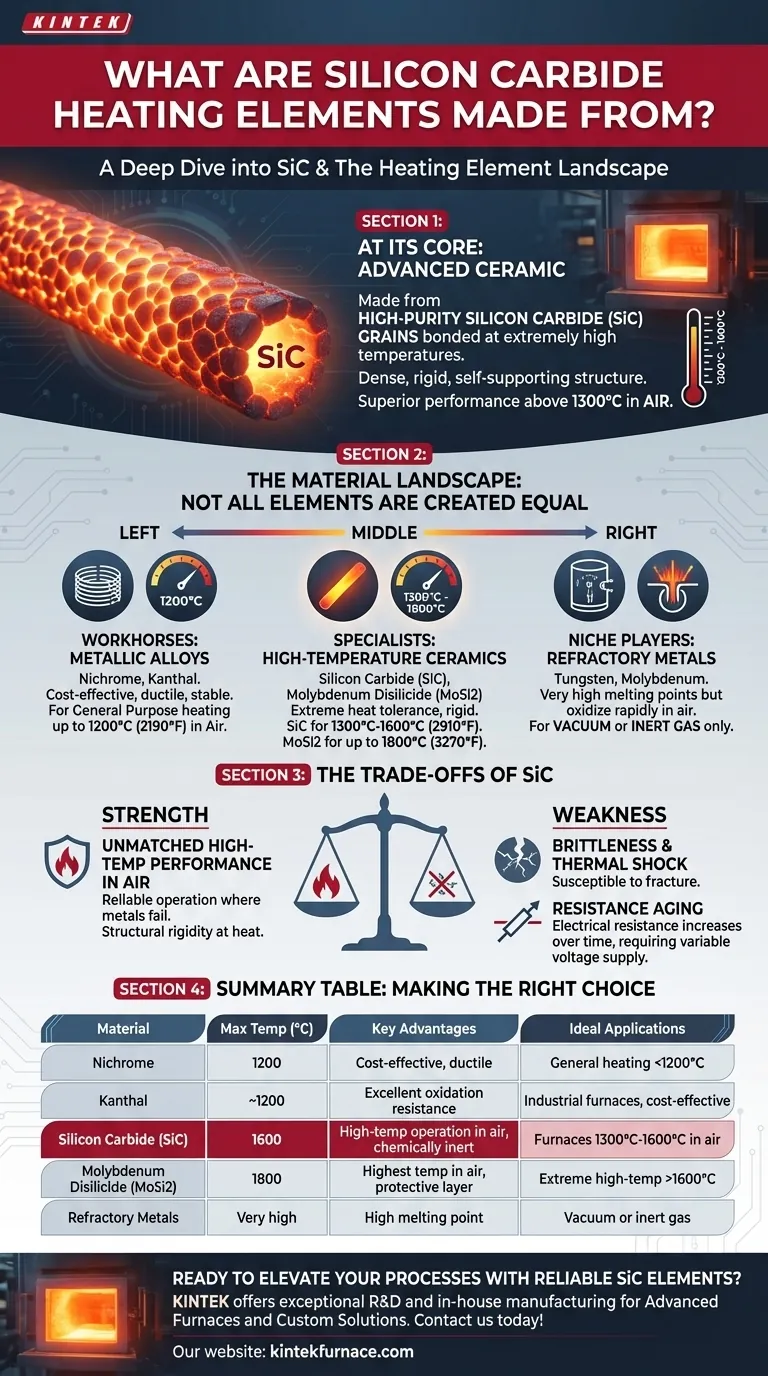

Understanding the Material Landscape

To appreciate why silicon carbide is used, you must first understand the landscape of heating element materials. They are not interchangeable; each is engineered for a specific operational window defined by temperature, atmosphere, and cost.

The Workhorses: Metallic Alloys

The most common heating elements are made from metallic alloys, primarily chosen for their ductility, stability, and cost-effectiveness at low to medium temperatures.

- Nichrome (Nickel-Chromium): This is the industry standard for general-purpose heating up to about 1200°C (2190°F). The chromium content forms a protective oxide layer that prevents the nickel from oxidizing and burning out.

- Kanthal (Iron-Chromium-Aluminum): Often seen as a competitor to Nichrome, FeCrAl alloys can sometimes reach slightly higher temperatures and are known for their excellent oxidation resistance. They are a cost-effective choice for many industrial furnaces.

The Specialists: High-Temperature Ceramics

When temperatures exceed the limits of metallic alloys, engineers turn to advanced ceramics. These materials trade the ductility of metal for extreme heat tolerance.

- Silicon Carbide (SiC): SiC elements excel in the 1300°C to 1600°C (2370°F to 2910°F) range. They are chemically inert and rigid, allowing them to be used in harsh industrial environments without supports.

- Molybdenum Disilicide (MoSi2): For the highest temperature ranges in air (up to 1800°C or 3270°F), MoSi2 is the premium choice. These elements form a protective silica glass layer at high temperatures, enabling remarkable performance.

The Niche Players: Refractory Metals

Certain metals have incredibly high melting points but a critical weakness: they oxidize rapidly in air at high temperatures.

- Tungsten & Molybdenum: These materials are used for very high-temperature applications, but almost exclusively in vacuum or inert gas atmospheres. SiC, by contrast, is designed to operate directly in air.

The Trade-offs of Using Silicon Carbide

No material is perfect. Choosing silicon carbide brings a distinct set of advantages and disadvantages that you must manage.

Strength: Unmatched High-Temperature Performance in Air

The primary reason to select SiC is its ability to operate reliably at temperatures that would destroy Nichrome or Kanthal elements. Its structural rigidity at heat is a significant operational advantage.

Weakness: Brittleness and Thermal Shock

As a ceramic, SiC is brittle. It cannot be bent or reshaped like a metal wire and is susceptible to fracture from mechanical impact or severe thermal shock (heating or cooling too rapidly).

Weakness: Resistance Aging

The electrical resistance of a silicon carbide element increases gradually over its service life. This phenomenon, known as aging, requires a power supply with variable voltage output to maintain consistent power and temperature, adding complexity to the system design. Metallic alloys, by contrast, have relatively stable resistance over their lifespan.

Making the Right Choice for Your Application

Selecting the correct heating element is a critical design decision based entirely on your operational goals.

- If your primary focus is general heating below 1200°C (2190°F): Choose a metallic alloy like Nichrome or Kanthal for the best balance of cost, durability, and ease of use.

- If your primary focus is furnace operation from 1300°C to 1600°C (2910°F) in an air atmosphere: Silicon Carbide is the definitive and most practical choice for this environment.

- If your primary focus is operating in a vacuum or inert gas at high temperatures: Refractory metals like molybdenum or tungsten are specifically designed for this purpose.

- If your primary focus is reaching the absolute highest temperatures (above 1600°C) in air: Molybdenum Disilicide (MoSi2) elements are engineered for this extreme performance bracket.

Ultimately, choosing a heating element is about precisely matching the material's properties to the demands of your application.

Summary Table:

| Material | Max Temperature (°C) | Key Advantages | Ideal Applications |

|---|---|---|---|

| Nichrome | 1200 | Cost-effective, ductile | General heating below 1200°C |

| Kanthal | ~1200 | Excellent oxidation resistance | Industrial furnaces, cost-effective heating |

| Silicon Carbide (SiC) | 1600 | High-temp operation in air, chemically inert | Furnaces from 1300°C to 1600°C in air |

| Molybdenum Disilicide (MoSi2) | 1800 | Highest temp in air, protective silica layer | Extreme high-temp applications above 1600°C |

| Refractory Metals (e.g., Tungsten) | Very high | High melting point | Vacuum or inert gas atmospheres |

Ready to elevate your high-temperature processes with reliable silicon carbide heating elements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs. Contact us today to discuss how our tailored heating elements can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights