In short, H Type Silicon Carbide (SiC) heating elements are most commonly used in the glass, chemical, and electronic materials industries. Their unique design makes them exceptionally reliable in processes that demand precise temperature control and involve frequent or rapid temperature changes.

The critical factor is not just the high temperatures SiC elements can achieve, but how they handle thermal stress. The H Type's specific construction gives it superior durability against the thermal shock of repeated heating and cooling cycles, defining its ideal use case.

Core Applications of the H Type Element

The H Type's specialization makes it the preferred choice in sectors where thermal cycling is a standard part of the process.

Glass and Quartz Manufacturing

Processes like quartz glass melting require intense, controlled heat. The H Type provides the necessary high temperatures while being robust enough to handle the thermal fluctuations inherent in melting and forming operations.

Electronic Materials and Crystal Growth

Manufacturing semiconductors and high-purity crystals involves precise thermal profiles. The H Type's reliability and resistance to rapid temperature changes are critical for achieving the strict conditions needed for high-temperature crystal growth.

Chemical Processing

Many chemical reactions require consistent and reliable heat to proceed correctly. The H Type delivers this stability, ensuring process integrity in demanding chemical production environments.

What Makes the H Type Unique?

While all SiC elements are durable, the H Type's physical design gives it a distinct advantage in specific scenarios. Its value comes from its structure.

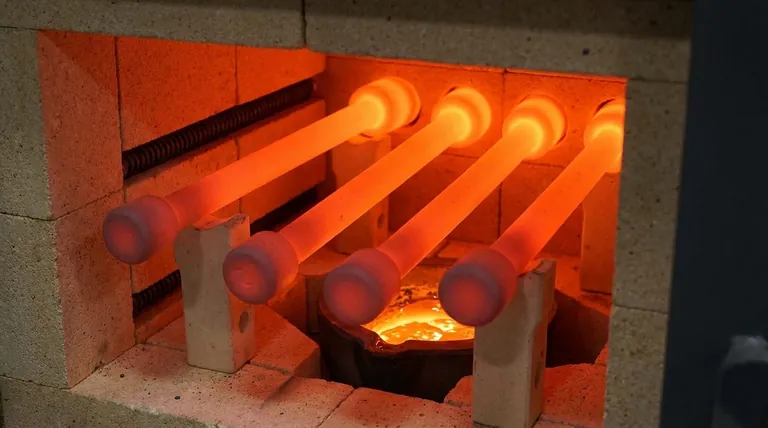

The Structural Design: A Thickened End

The H Type is a hollow tube with a distinctively thickened end. This simple but effective design feature reinforces the element at a critical stress point.

Superior Thermal Shock Resistance

This thickened construction significantly enhances its ability to withstand rapid heating and cooling. Where other elements might deform or fracture under repeated thermal stress, the H Type maintains its integrity.

Reliability in Fluctuating Conditions

This durability makes it ideal for batch furnaces or laboratory equipment where processes are started and stopped frequently. Its resistance to thermal shock translates directly to a longer service life and greater operational reliability in these environments.

Understanding the Trade-offs: H Type vs. Other SiC Elements

Choosing the right element means understanding its specific strengths compared to other available types.

Comparison with the DM Type

The DM Type is a versatile workhorse, widely used for general-purpose applications in industrial furnaces for metal heat treatment, ceramics, and semiconductor manufacturing. It is chosen for its stable, controlled heat in less demanding thermal cycles.

Comparison with the SC Type

The SC Type is designed for spatial temperature uniformity. It is the ideal choice for large-scale furnaces where consistent heat must be applied evenly across the bottom or sides of a large heating chamber.

When to Choose the H Type

You choose the H Type specifically when your process involves cyclic heating. If your furnace or equipment will be turned on and off frequently or undergo rapid temperature ramps, the H Type's superior resistance to thermal shock makes it the most durable and reliable option.

Making the Right Choice for Your Process

Your decision should be driven by the specific thermal demands of your application.

- If your primary focus is durability under thermal cycling: The H Type is engineered specifically for its ability to withstand the stress of rapid heating and cooling.

- If your primary focus is uniform heat across a large area: The SC Type is designed to provide excellent spatial temperature consistency in large furnaces.

- If your primary focus is general high-temperature reliability: The DM Type serves as a robust and versatile option for a wide range of standard industrial processes.

Ultimately, selecting the correct heating element is about matching the component's design strengths to the unique challenges of your thermal process.

Summary Table:

| Application | Key Benefit |

|---|---|

| Glass and Quartz Manufacturing | Handles thermal fluctuations in melting processes |

| Electronic Materials and Crystal Growth | Ensures reliability in rapid temperature changes |

| Chemical Processing | Provides consistent heat for reaction integrity |

Optimize your thermal processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our H Type SiC heating elements can enhance durability and efficiency in your lab or production environment!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency