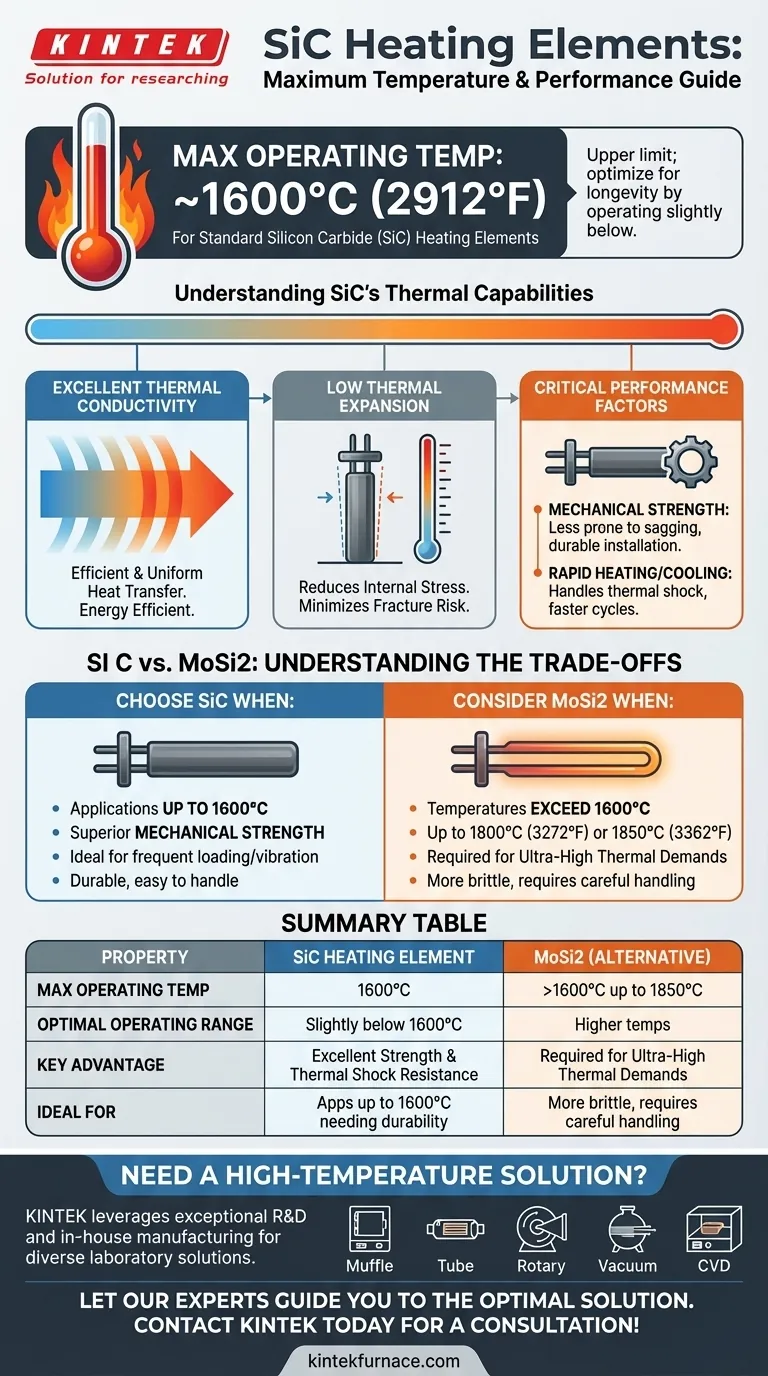

In practice, the maximum operating temperature for a standard Silicon Carbide (SiC) heating element is approximately 1600°C (2912°F). While this figure represents the upper limit, most industrial applications run these elements at slightly lower temperatures to ensure a long and reliable service life.

Choosing the right heating element is not just about finding the highest temperature rating. It's about matching the element's specific properties—like its thermal limits, mechanical strength, and chemical resistance—to the precise demands of your furnace or process.

Understanding SiC's Thermal Capabilities

Silicon Carbide is a premier material for high-temperature applications due to its unique combination of thermal and physical properties. It serves as a reliable workhorse for a vast range of industrial heating processes.

Maximum Operating Temperature

The generally accepted maximum surface temperature for SiC elements is 1600°C (2912°F). Operating continuously at or near this absolute limit can shorten the element's lifespan.

For optimal performance and longevity, a slightly lower continuous operating temperature is a standard best practice in furnace design and operation.

Excellent Thermal Conductivity

SiC elements possess excellent thermal conductivity. This allows for highly efficient and uniform heat transfer from the element to the chamber and the product being heated.

This efficiency ensures that energy is not wasted and that temperature uniformity within the furnace is easier to achieve and maintain.

Low Thermal Expansion

A key advantage of SiC is its very low coefficient of thermal expansion. This means the element expands and contracts very little as it heats and cools.

This inherent stability dramatically reduces internal stresses, minimizing the risk of fracture or breakage during rapid temperature changes and extending the element's useful life.

Beyond Temperature: Critical Performance Factors

While temperature is a primary consideration, the mechanical resilience of SiC is what makes it a superior choice for many demanding environments.

Mechanical Strength and Durability

Compared to many other ceramic and metallic heating elements, SiC exhibits outstanding mechanical strength. It is rigid and less prone to sagging or deforming at high temperatures.

This durability reduces the risk of breakage during installation, maintenance, or from accidental contact, lowering replacement costs and operational downtime.

Rapid Heating and Cooling Rates

The combination of high thermal conductivity and excellent thermal shock resistance allows SiC elements to handle rapid heating and cooling cycles.

This capability can significantly speed up process times, improve throughput, and reduce overall energy consumption by minimizing the time the furnace must idle at high temperatures.

Understanding the Trade-offs: SiC vs. MoSi2

While SiC is exceptionally capable, it is not the only option for high-temperature heating. Understanding its primary alternative, Molybdenum Disilicide (MoSi2), is critical for making an informed decision.

When to Choose SiC

SiC is the ideal choice for most industrial applications operating up to 1600°C. Its superior mechanical strength makes it more robust and easier to handle than MoSi2, especially in applications with frequent loading/unloading or potential for mechanical vibration.

When to Consider MoSi2

Molybdenum Disilicide (MoSi2) elements are required when process temperatures must exceed the limits of SiC. MoSi2 can operate at extremely high temperatures, often up to 1800°C (3272°F) or even 1850°C (3362°F).

You must select MoSi2 for applications like sintering certain advanced ceramics, crystal growing, or specific laboratory tests that demand temperatures beyond the capability of Silicon Carbide.

Key Differences to Note

The primary trade-off is temperature versus robustness. MoSi2 can achieve higher temperatures but is more brittle, particularly at lower temperatures, and requires more careful handling. SiC offers exceptional durability within its slightly lower temperature range.

Making the Right Choice for Your Application

Selecting the correct element requires balancing your temperature requirements against the mechanical and operational demands of your process.

- If your primary focus is robust performance and durability up to 1600°C: SiC is the superior and more reliable choice due to its mechanical strength.

- If your process absolutely requires temperatures between 1600°C and 1850°C: MoSi2 is the necessary technology to meet these ultra-high thermal demands.

- If your furnace undergoes frequent thermal cycling or mechanical stress: The inherent strength and low thermal expansion of SiC provide a significant advantage in longevity.

Ultimately, your decision hinges on matching the element's specific strengths to your application's absolute temperature and durability needs.

Summary Table:

| Property | SiC Heating Element |

|---|---|

| Max Operating Temperature | 1600°C (2912°F) |

| Optimal Operating Range | Slightly below 1600°C |

| Key Advantage | Excellent mechanical strength & thermal shock resistance |

| Ideal For | Applications up to 1600°C requiring durability and rapid cycling |

| Primary Alternative | MoSi2 (for temperatures >1600°C up to 1850°C) |

Need a High-Temperature Heating Solution Tailored to Your Process?

Choosing between SiC and MoSi2 elements is critical for your furnace's performance and longevity. KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions.

Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability. We can help you select or design the perfect heating element to precisely meet your unique temperature and durability requirements.

Let our experts guide you to the optimal solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions