A rotary kiln's high throughput is primarily achieved through its fundamental design as a continuous processing system, combined with its immense physical scale and efficient internal mechanics for moving and heating material. Unlike batch systems that must stop and start, a kiln is engineered to feed, process, and discharge material in an uninterrupted flow, 24/7.

The core reason for a rotary kiln's high throughput is not a single feature, but its holistic design as a dedicated, continuous-flow chemical reactor. Its entire structure is optimized to eliminate downtime and process massive volumes of material without interruption.

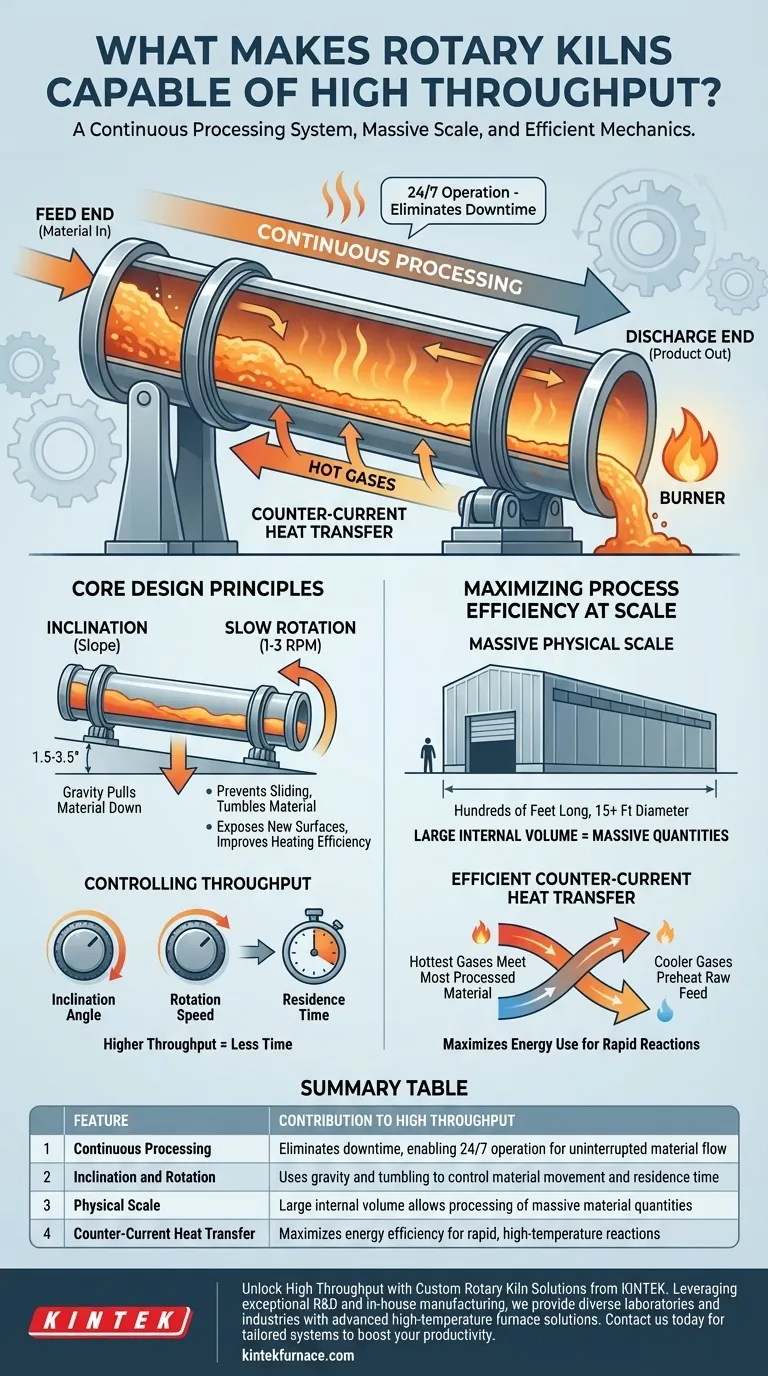

The Foundation: Continuous, Uninterrupted Processing

The most significant factor enabling high throughput is the shift from batch processing to a continuous operational model. This design philosophy underpins every other feature of the kiln.

From Batch to Continuous Flow

Batch processors must be loaded, run, cooled, and emptied in separate, time-consuming steps. This creates significant non-productive downtime between cycles.

A rotary kiln eliminates this entirely. Raw material is continuously fed into the upper end while finished product is simultaneously discharged from the lower end, creating a non-stop production line.

Designed for 24/7 Operation

Rotary kilns are built for extreme durability, often using welded, heavy-gauge steel shells lined with refractory brick.

This robust construction allows them to run for months, or even years, without being shut down for major maintenance. Maximizing uptime is essential for achieving high annual throughput targets.

Core Design Principles for Material Transport

The simple yet effective mechanism for moving material through the kiln is key to its reliability and high capacity. This movement is governed by two intentional design choices: inclination and rotation.

The Role of Inclination (Slope)

A rotary kiln is not installed perfectly level. It is mounted at a slight angle, typically between 1.5 and 3.5 degrees.

This slight downward slope uses gravity to help pull material from the feed end toward the discharge end, providing a constant and reliable motive force.

The Power of Slow Rotation

The kiln rotates slowly on its axis, usually between 1 to 3 revolutions per minute (RPM). This rotation serves two critical functions.

First, it prevents material from simply sliding down the bottom of the kiln. Instead, it tumbles the material, ensuring it moves forward in a controlled, predictable manner.

Second, this tumbling action constantly mixes the material bed, exposing new surfaces to the hot gases inside the kiln, which dramatically improves the efficiency of the heating process.

Controlling Throughput and Residence Time

The combination of inclination angle and rotation speed dictates the residence time—how long material spends inside the kiln.

Operators can adjust these parameters to speed up or slow down the process. Higher throughput is achieved with a steeper angle or faster rotation, which reduces residence time.

Maximizing Process Efficiency at Scale

Throughput isn't just about moving material quickly; the chemical or physical process must also keep pace. The kiln's design creates an incredibly efficient environment for high-temperature reactions.

The Advantage of Physical Scale

Rotary kilns are massive pieces of equipment, often hundreds of feet long with diameters of 15 feet or more.

This sheer size provides an enormous internal volume, allowing a large quantity of material to be processed at any given moment, directly contributing to its high-volume capacity.

Efficient Counter-Current Heat Transfer

In most designs, the material flows downhill while the hot combustion gases from the burner at the lower end flow uphill, creating a counter-current flow.

This is the most thermodynamically efficient method of heat transfer. It ensures that the hottest gases meet the most-processed material, while the cooler gases preheat the incoming raw feed, maximizing energy use and enabling the rapid reactions required for high throughput.

Understanding the Trade-offs

The rotary kiln's design for high throughput comes with significant operational considerations. It is a specialized tool, not a universal solution.

High Capital and Energy Costs

The massive scale and robust construction make rotary kilns extremely expensive to build and install. Furthermore, their continuous, high-temperature operation results in very high energy consumption, primarily from fuel for the burner.

Inherent Lack of Flexibility

A kiln is typically designed and optimized for a single, specific process and feedstock. It cannot be easily reconfigured to handle different materials or small, varied batches. Its strength is in consistent, high-volume production of one thing.

Long Start-up and Shut-down Periods

Due to their massive thermal mass, bringing a kiln up to operating temperature can take several days. Likewise, cooling one down is a slow, controlled process. This reinforces their unsuitability for intermittent or short-run production needs.

Making the Right Choice for Your Goal

Selecting a rotary kiln is a decision driven entirely by the need for continuous, large-scale production.

- If your primary focus is maximum output of a single commodity: The rotary kiln's continuous flow and massive scale are unparalleled for industries like cement, lime, and alumina production.

- If your primary focus is processing diverse, small-volume batches: A rotary kiln's lack of flexibility and long heat-up times make it the wrong tool; batch furnaces or indirect calciners would be more appropriate.

- If your primary focus is balancing throughput with cost: Optimizing the kiln's process controls, especially rotation speed and burner efficiency, is critical to managing its significant energy overhead.

Ultimately, a rotary kiln's design brilliantly leverages gravity and rotation to enable a continuous, efficient industrial process at a massive scale.

Summary Table:

| Feature | Contribution to High Throughput |

|---|---|

| Continuous Processing | Eliminates downtime, enabling 24/7 operation for uninterrupted material flow |

| Inclination and Rotation | Uses gravity and tumbling to control material movement and residence time |

| Physical Scale | Large internal volume allows processing of massive material quantities |

| Counter-Current Heat Transfer | Maximizes energy efficiency for rapid, high-temperature reactions |

Unlock High Throughput with Custom Rotary Kiln Solutions from KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need scalable, continuous processing for industries like cement or lime, or tailored solutions for specific materials, we deliver reliable, efficient systems to boost your productivity and reduce operational costs.

Contact us today to discuss how our expertise can optimize your high-throughput processes!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results