At their core, electrically heated rotary kilns offer a level of temperature control that is fundamentally more precise, responsive, and uniform than their fuel-fired counterparts. This is because electric heating allows for direct and rapid modulation of energy input without the complexities of combustion, enabling superior performance across the entire temperature spectrum, especially in lower ranges where gas systems often falter.

The crucial advantage is not simply hitting a target temperature, but creating a perfectly managed thermal environment. This precision translates directly into higher product quality, greater process efficiency, and the ability to process sensitive materials that are intolerant of temperature fluctuations.

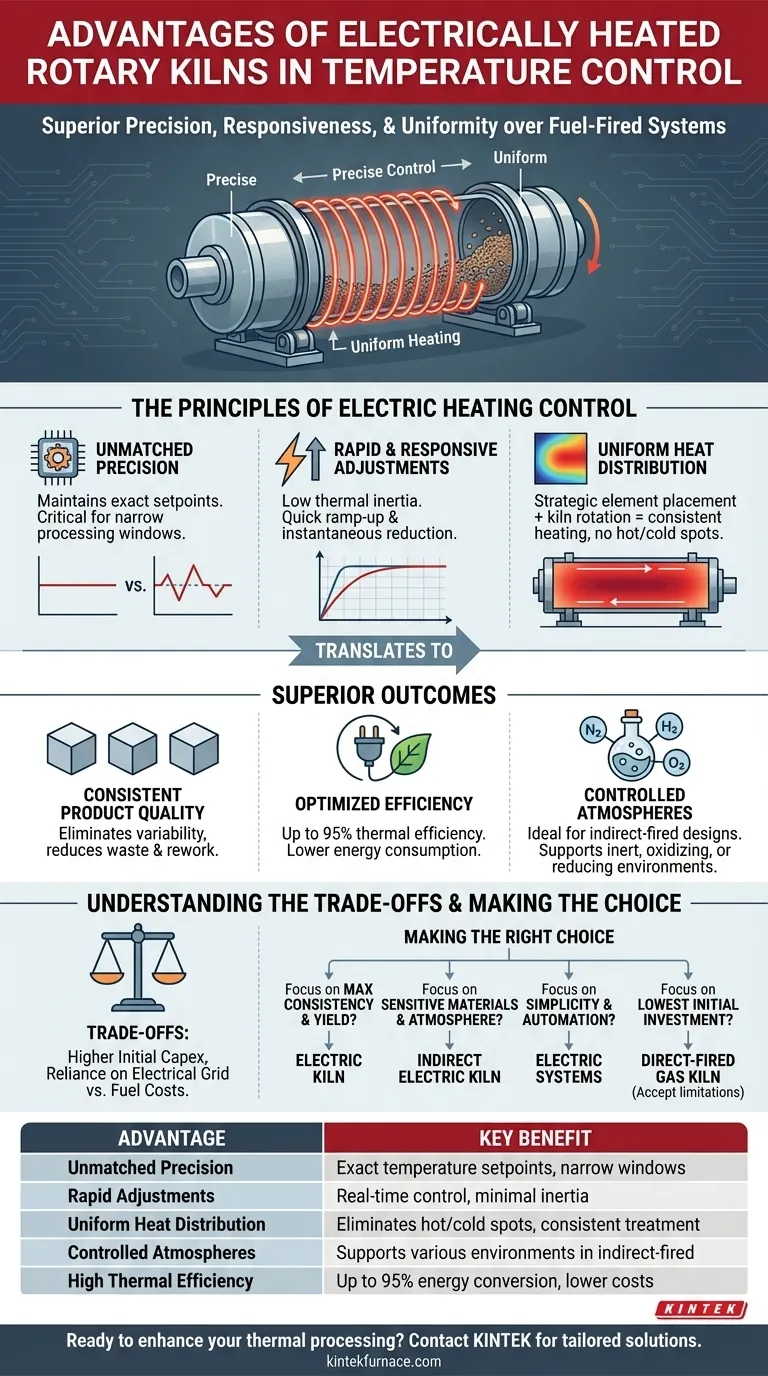

The Principles of Electric Heating Control

To understand the benefits, we must first look at how electric heating fundamentally differs from combustion-based methods within a rotary kiln. The control is more direct and inherently more stable.

Unmatched Precision for Demanding Processes

Electric heating elements can be controlled with exceptional accuracy. The power supplied can be adjusted in small, precise increments, allowing the system to maintain a temperature setpoint with minimal deviation.

This is critical for materials with narrow processing windows, where even a few degrees of variation can negatively impact the final product quality.

Rapid and Responsive Adjustments

Electric systems lack the thermal inertia of large combustion chambers. They can ramp up to temperature quickly and, just as importantly, reduce heat input almost instantaneously.

This responsiveness allows for dynamic process control, where the temperature profile can be adjusted in real-time based on sensor feedback, ensuring the material receives the exact thermal treatment required.

Uniform Heat Distribution

The design of an electric kiln allows for the strategic placement of heating elements along the length of the kiln shell. When combined with the constant tumbling motion of the material from the kiln's rotation, this ensures remarkably uniform heating.

This synergy prevents local overheating or underheating, known as hot or cold spots, which are a common challenge in direct-fired kilns. Every particle of the material is exposed to the same thermal conditions, guaranteeing consistency.

How Precise Control Translates to Superior Outcomes

Superior temperature control is not just a technical feature; it is a direct driver of operational value, impacting everything from product yield to environmental footprint.

Guaranteeing Consistent Product Quality

The primary benefit of uniform and precise heating is the elimination of process variability. This prevents the over-processing or under-processing of material, resulting in a consistently higher-quality output and a significant reduction in waste and rework.

Optimizing Process and Energy Efficiency

Modern electric kilns boast extremely high thermal efficiency, often up to 95%. The energy is converted to heat directly where it is needed—within the processing chamber—with no heat lost to flue gases or exhaust.

This simplified and efficient operation means lower energy consumption per unit of product, which can make it more economical than gas or oil, depending on local utility costs.

Enabling Controlled Processing Atmospheres

Because there is no combustion, electric kilns are ideal for indirect-fired designs. In these systems, the material is contained within a rotating retort, which is heated from the outside.

This separation makes it possible to maintain precise control over the internal processing atmosphere. Whether your process requires an inert, oxidizing, or reducing environment, an indirect electric kiln provides the control that is impossible to achieve with direct-fired combustion.

Understanding the Trade-offs

While offering clear advantages in control, electric kilns are not the universal solution for every application. Acknowledging the trade-offs is key to making an objective decision.

Initial Capital Expenditure

Electrically heated rotary kilns, particularly highly customized or induction-based systems, can have a higher upfront cost compared to simpler, direct-fired gas kilns. This investment must be weighed against the long-term gains in product quality and efficiency.

Reliance on Electrical Infrastructure

Effective operation requires a robust and stable electrical supply capable of handling the significant power demands of the kiln. In locations with unreliable grids or very high electricity prices, the operational cost benefits may be diminished.

Comparison to Fuel-Fired Systems

In regions where natural gas or oil prices are exceptionally low relative to electricity, a fuel-fired kiln may present a lower total cost of ownership, provided its lesser degree of temperature control is acceptable for the material being processed.

Making the Right Choice for Your Goal

Your choice of heating technology should be dictated by the specific demands of your material and your operational priorities.

- If your primary focus is maximum product consistency and yield: The unparalleled precision and uniformity of an electric kiln is the definitive choice.

- If your primary focus is processing highly sensitive or reactive materials: The combination of precise temperature and atmosphere control in an indirect electric kiln is non-negotiable.

- If your primary focus is operational simplicity and automation: Electric systems offer simpler, more programmable control without the complexity of fuel management and combustion monitoring.

- If your primary focus is the lowest possible initial investment: A direct-fired gas kiln may be a suitable starting point, but you must accept the inherent limitations in process control.

By aligning the technology's capabilities with your process requirements, you can select the thermal processing solution that truly empowers your operation.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Unmatched Precision | Maintains exact temperature setpoints for narrow processing windows |

| Rapid Adjustments | Enables real-time control with minimal thermal inertia |

| Uniform Heat Distribution | Eliminates hot/cold spots for consistent material treatment |

| Controlled Atmospheres | Supports inert, oxidizing, or reducing environments in indirect-fired designs |

| High Thermal Efficiency | Up to 95% energy conversion, reducing operational costs |

Ready to enhance your laboratory's thermal processing with precise, reliable solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our electrically heated rotary kilns can optimize your process efficiency and product quality!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- What is the retention time of a rotary kiln? Optimize Your Process Efficiency