At its core, the suitability of Microwave Plasma Chemical Vapor Deposition (MPCVD) for industrial applications stems from its unique combination of stability, scalability, and the ability to produce exceptionally high-purity diamond films. This method uses microwave energy to create a clean, electrode-less plasma, enabling continuous, reproducible manufacturing processes that meet the stringent demands of modern industry.

The critical insight is that MPCVD decouples the plasma generation from the reaction chamber itself. By using microwaves, it avoids the contamination and instability inherent in other methods, making it the most reliable and controllable technique for producing high-quality, single-crystal diamond at an industrial scale.

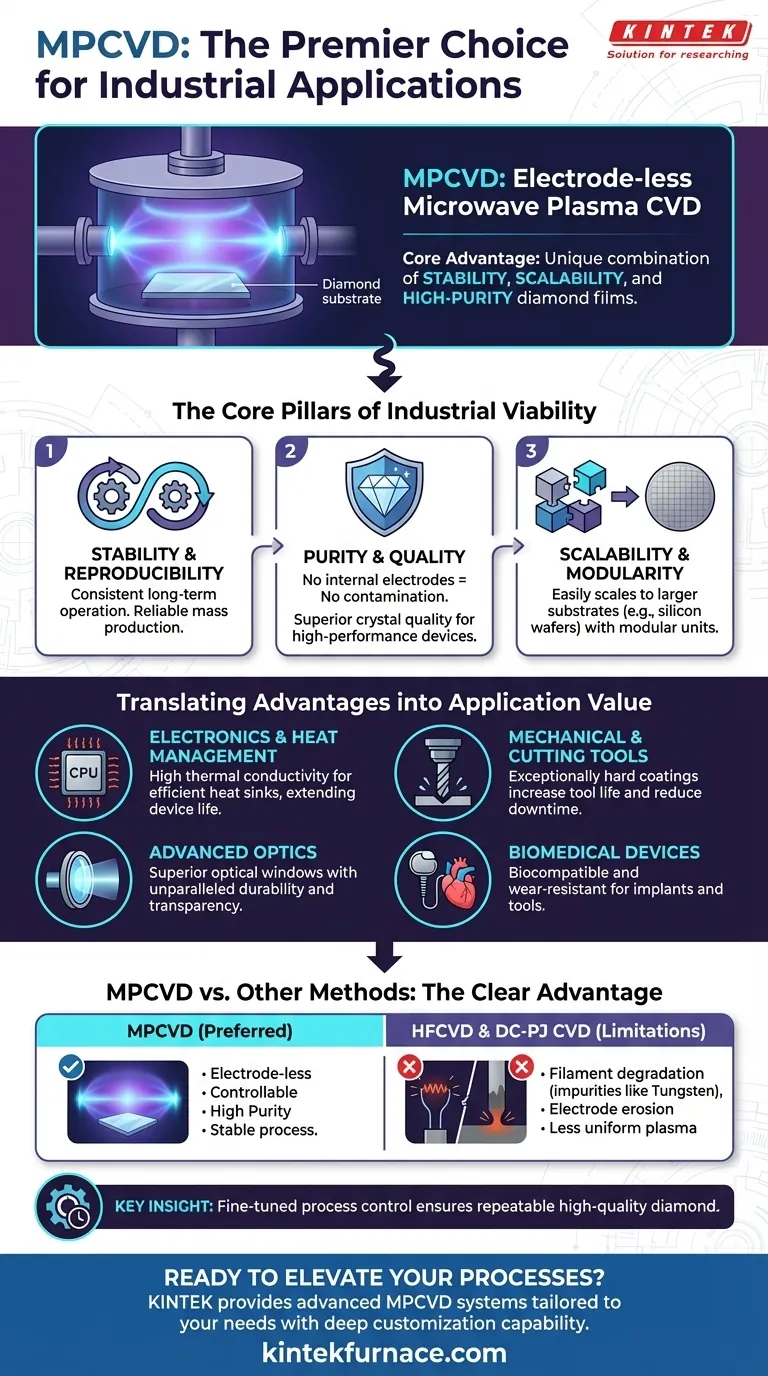

The Core Pillars of Industrial Viability

To be viable for industrial use, a technology must be reliable, repeatable, and adaptable to production demands. MPCVD excels in these three fundamental areas.

Stability and Reproducibility

The process is exceptionally stable over long durations. This allows for continuous operation, a prerequisite for any mass-production environment.

This stability ensures that the quality of the diamond film remains consistent from one batch to the next, which is critical for applications like semiconductors and precision optics.

Purity and Quality: The Electrode-less Advantage

MPCVD utilizes microwaves to excite gases into a plasma. Because there are no internal electrodes, a primary source of contamination in other systems is completely eliminated.

This results in diamond films with superior crystal quality and freedom from impurities, a non-negotiable requirement for high-performance electronic and optical devices.

Scalability and Modularity

MPCVD systems are often designed with modular units, typically using a 1-2 kW microwave power supply.

This modularity allows for the process to be easily scaled up to accommodate larger substrates, such as full-size silicon wafers. This is a key advantage for integrating diamond into the semiconductor industry.

Translating Technical Advantages into Application Value

The theoretical benefits of MPCVD translate directly into tangible performance gains across a wide range of industries. The high quality of the diamond produced unlocks new capabilities.

Electronics and Heat Management

The high thermal conductivity of MPCVD diamond makes it an ideal material for heat sinks in high-power electronics. This effective heat dissipation extends device lifespan and improves performance.

Mechanical and Cutting Tools

MPCVD creates exceptionally hard diamond coatings. When applied to cutting tools, these coatings dramatically increase tool life and performance, reducing manufacturing downtime and costs.

Advanced Optics

The purity and perfect crystal structure of MPCVD diamond result in superior optical windows. They offer unparalleled durability and transparency across a wide spectrum, crucial for lasers and sensors operating in harsh environments.

Biomedical Devices

The diamond films are biocompatible and highly wear-resistant. This makes MPCVD a valuable process for creating durable coatings for medical implants and surgical tools, reducing wear and improving patient outcomes.

Understanding the Trade-offs: MPCVD vs. Other Methods

While MPCVD is a sophisticated technique, its advantages become clear when compared to alternative diamond synthesis methods. Its superiority is not universal but is pronounced for high-value applications.

Why MPCVD is Preferred over HFCVD

Hot Filament CVD (HFCVD) uses a heated filament to activate the gases. This filament degrades over time, introducing impurities (like tungsten) into the diamond film and creating process instability. MPCVD's electrode-less nature completely avoids this critical flaw.

The Edge Over DC-PJ CVD

Direct Current Plasma Jet (DC-PJ) CVD can suffer from electrode erosion, which also introduces contaminants. The plasma can be less uniform and stable than that produced by microwaves, making it more difficult to achieve the high quality and control required for single-crystal diamond on large substrates.

Process Control as the Deciding Factor

Ultimately, the fine-tuned control over reaction conditions is what sets MPCVD apart. The ability to precisely manage gas composition, pressure, and temperature ensures the repeatable production of high-quality diamond, making it the most trusted method for demanding industrial goals.

Making the Right Choice for Your Application

Selecting the right deposition technology depends entirely on your end goal. The trade-offs between cost, quality, and scale are paramount.

- If your primary focus is the highest-purity electronic or optical-grade diamond: MPCVD is the definitive and most reliable choice due to its contamination-free process.

- If your primary focus is scaling production for large substrates: MPCVD's modular and stable design provides a clear and proven path for industrial-scale manufacturing.

- If your primary focus is cost-sensitive wear-resistant coatings where minor impurities are tolerable: Alternative methods might be considered, but MPCVD still offers superior process control and long-term reliability.

By mastering the controllable and clean synthesis of diamond, MPCVD empowers industries to leverage this extraordinary material for next-generation technology.

Summary Table:

| Key Advantage | Industrial Benefit |

|---|---|

| Stability & Reproducibility | Enables continuous, reliable manufacturing with consistent quality |

| Purity & Electrode-less Plasma | Eliminates contamination for high-performance electronic and optical devices |

| Scalability & Modularity | Supports large substrates and easy production scale-up |

| High-Quality Diamond Films | Enhances heat management, tool durability, and optical performance |

Ready to elevate your industrial processes with high-purity diamond solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced MPCVD systems tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our MPCVD technology can drive innovation and efficiency in your applications!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What are the operational benefits of using a CVD Tube Furnace? Enhance Precision and Efficiency in Your Lab