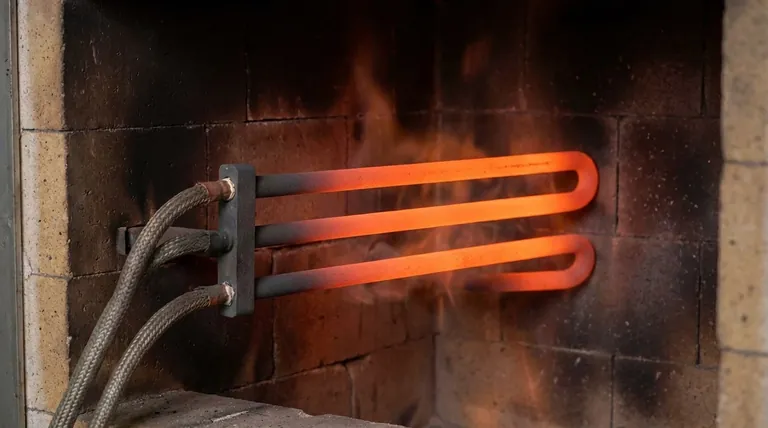

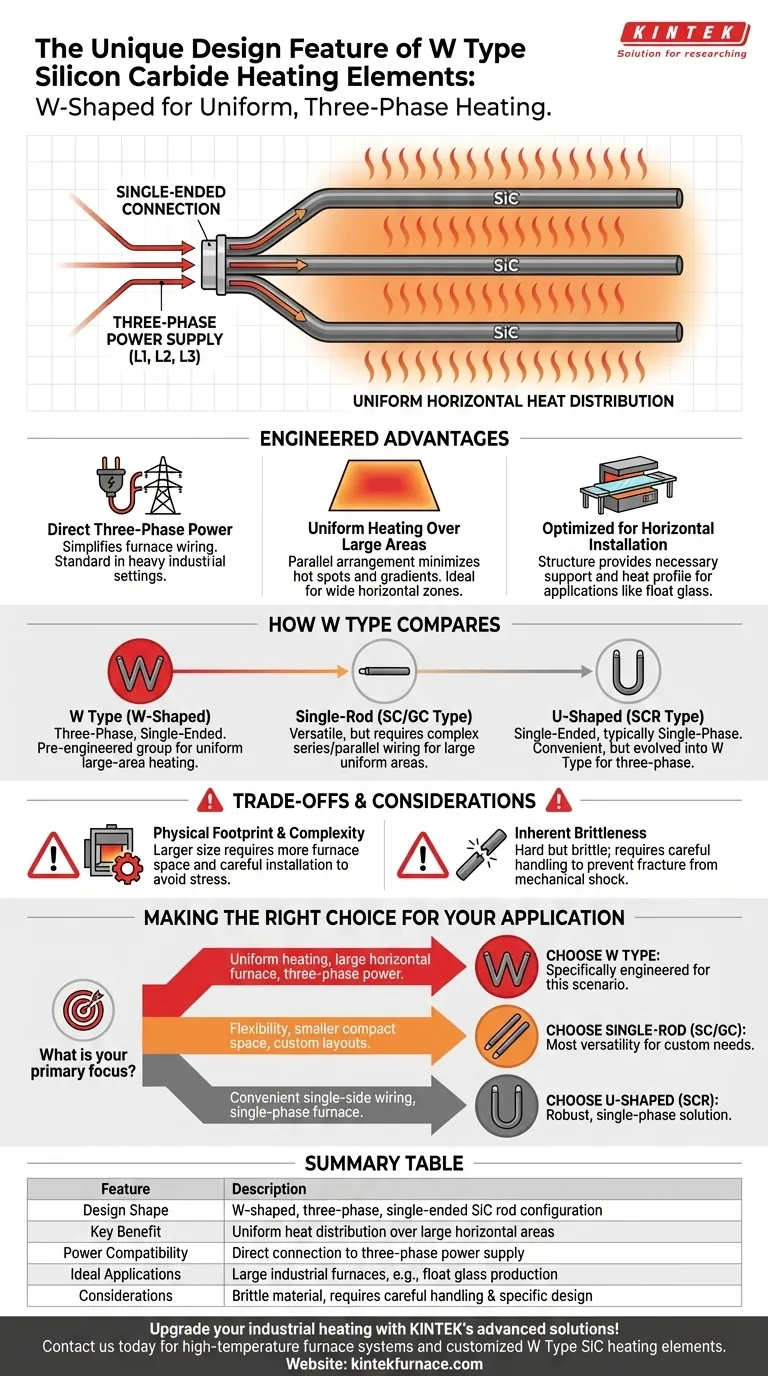

At its core, the unique design feature of a W Type Silicon Carbide (SiC) heating element is its three-phase, single-ended construction. This element consists of one SiC rod connected to three high-purity SiC rods at one end, forming a distinct "W" shape. This configuration allows it to be wired directly to a three-phase power supply from a single connection point.

The W-shaped design is not an arbitrary choice; it is an engineered solution to deliver highly uniform heat across a large horizontal area while simplifying the electrical connections required for high-power, three-phase industrial furnaces.

The Functional Purpose of the W-Shaped Design

The specific geometry of the W Type element is directly tied to solving common challenges in large-scale industrial heating applications. It provides a unique combination of electrical efficiency and optimized thermal distribution.

Engineered for Horizontal Installation

The W shape provides the necessary structure and heat distribution profile for horizontal mounting. This is critical in applications like float glass production lines where heat must be applied evenly from above or below a moving surface.

Uniform Heating Over Large Areas

By arranging three heating sections in parallel, the W Type element creates a broad, even thermal field. This design minimizes hot spots and temperature gradients, which is essential for processes requiring precise temperature control over a wide zone.

Direct Three-Phase Power Compatibility

This is the element's most significant electrical advantage. In heavy industrial settings, three-phase power is standard. The W Type's three "legs" can be connected directly to the three phases of the power supply, simplifying furnace wiring and power control systems.

How W Type Compares to Other SiC Elements

Understanding the W Type requires seeing it in context with other common designs. Each type is a tool engineered for a specific thermal task.

W Type vs. Single-Rod (SC/GC Type)

Single-rod elements, whether solid (SC) or tubular (GC), are the most basic form. While versatile, achieving uniform heat over a large area with them requires wiring many individual elements in complex series or parallel groups. The W Type is essentially a pre-engineered, three-phase group in a single component.

W Type vs. U-Shaped (SCR Type)

U-shaped elements also allow for single-side connection, which is convenient for furnace design and maintenance. However, they are typically two-rod, single-phase elements. The W Type is an evolution of this concept, purpose-built for three-phase systems.

Understanding the Trade-offs and Considerations

While powerful, the W Type design is not a universal solution. Its specialized nature comes with specific considerations.

Physical Footprint and Complexity

The W shape is inherently larger and more complex than a simple rod or U-shaped element. This requires more space within the furnace and careful handling during installation to avoid mechanical stress on the connection point.

Application Specificity

These elements are highly optimized for a specific job: large, horizontal, three-phase furnaces. Using them in a small, single-phase, or vertically oriented furnace would be inefficient and unnecessarily complex compared to using simpler rod or U-shaped elements.

Inherent Brittleness

Like all silicon carbide heating elements, the W Type is hard and resistant to high temperatures but is also brittle. Its complex shape means it must be handled and installed with care to prevent fracture from mechanical shock or improper support.

Making the Right Choice for Your Application

Selecting the correct heating element geometry is fundamental to achieving process efficiency, temperature uniformity, and operational reliability.

- If your primary focus is uniform heating in a large horizontal furnace with a three-phase power supply: The W Type is specifically engineered for this scenario, simplifying wiring and ensuring even heat distribution.

- If your primary focus is flexibility or heating a smaller, more compact space: Simple single-rod (SC or GC) elements offer the most versatility for custom layouts and smaller furnaces.

- If your primary focus is convenient single-side wiring in a single-phase furnace: The U-shaped (SCR) element provides a robust and proven solution without the complexity of a three-phase design.

Ultimately, choosing the right element is about matching the component's design intent to the specific demands of your thermal process.

Summary Table:

| Feature | Description |

|---|---|

| Design Shape | W-shaped, three-phase, single-ended SiC rod configuration |

| Key Benefit | Uniform heat distribution over large horizontal areas |

| Power Compatibility | Direct connection to three-phase power supply |

| Ideal Applications | Large industrial furnaces, e.g., float glass production |

| Considerations | Brittle material, requires careful handling and specific furnace design |

Upgrade your industrial heating with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs. Contact us today to discuss how our W Type SiC heating elements and other products can enhance your process efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights