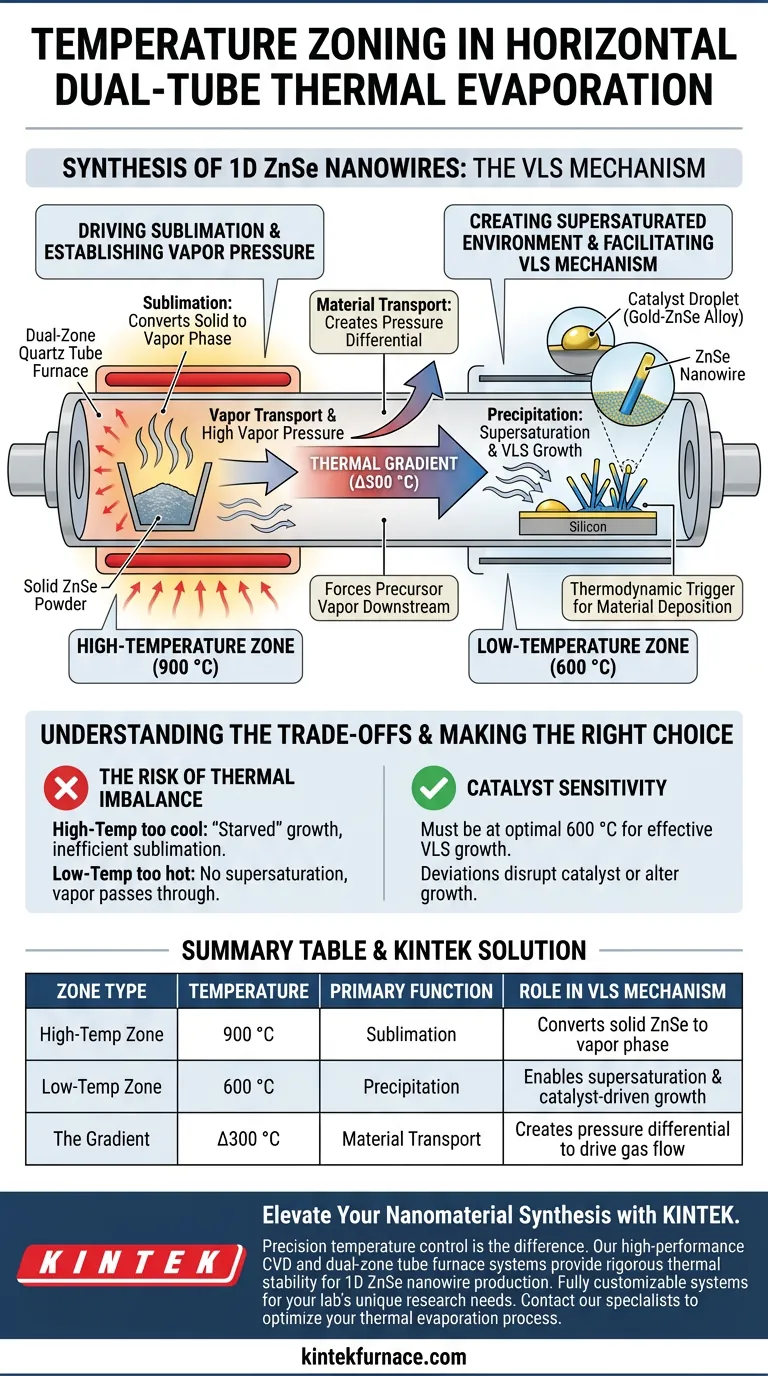

Temperature zoning is the fundamental mechanism that drives material transport and phase transformation in the synthesis of 1D ZnSe nanowires. In a horizontal dual-tube thermal evaporation system, creating distinct high-temperature and low-temperature regions establishes a controlled thermal gradient. This gradient forces the source material to sublimate into a vapor at one end and precipitate as a solid nanostructure at the other.

The dual-zone setup is the engine behind the Vapor-Liquid-Solid (VLS) mechanism. By physically separating the source evaporation (900 °C) from the nanowire growth (600 °C), the system ensures that precursor vapor becomes supersaturated exactly where the catalyst is located.

The High-Temperature Zone: Initiating Transport

Driving Sublimation

The primary function of the high-temperature zone is to overcome the energy barrier required for sublimation.

Typically set at 900 °C, this zone provides the thermal energy necessary to convert solid ZnSe powder directly into a gas phase. Without this specific heat threshold, the source material would remain inert, and no vapor transport would occur.

Establishing Vapor Pressure

High temperatures generate a high concentration of ZnSe vapor.

This creates a pressure differential that naturally drives the gas downstream toward cooler regions. This flow of material is the feedstock for the eventual growth of nanowires.

The Low-Temperature Zone: Enabling Growth

Creating a Supersaturated Environment

The downstream zone, typically maintained at 600 °C, is engineered to lower the solubility of the gas.

As the hot vapor travels into this cooler region, it can no longer remain in the gaseous phase. This state of supersaturation is the thermodynamic trigger that forces the material to deposit back into a solid form.

Facilitating the VLS Mechanism

This specific temperature regime is critical for the Vapor-Liquid-Solid (VLS) growth process.

At 600 °C, the vapor interacts with a gold-film catalyst on a silicon substrate. The temperature is high enough to facilitate the liquid alloy formation but low enough to promote the precipitation of oriented ZnSe nanowires from the catalyst droplet.

Understanding the Trade-offs

The Risk of Thermal Imbalance

The success of this system relies entirely on the precise delta (difference) between the two zones.

If the high-temperature zone is too cool, sublimation will be inefficient, resulting in a "starved" growth environment with insufficient raw material. Conversely, if the low-temperature zone is too hot, supersaturation will not occur, and the vapor will simply pass through the tube without depositing.

Catalyst Sensitivity

The low-temperature zone is strictly bound by the properties of the catalyst.

The temperature must be maintained at a point where the gold catalyst remains effective for VLS growth. Deviating significantly from the optimal 600 °C setpoint can disrupt the catalyst's liquid state or alter the growth direction of the nanowires.

Making the Right Choice for Your Goal

To achieve high-quality 1D ZnSe nanowires, you must treat temperature not as a static setting, but as a dynamic flow control.

- If your primary focus is increasing growth rate: Ensure the high-temperature zone is stable at 900 °C to maximize the production of precursor vapor.

- If your primary focus is controlling morphology and orientation: Rigorously maintain the low-temperature zone at 600 °C to ensure the thermodynamic conditions favor precise VLS precipitation.

Mastering the thermal gradient is the single most important factor in converting raw powder into organized, one-dimensional nanostructures.

Summary Table:

| Zone Type | Temperature | Primary Function | Role in VLS Mechanism |

|---|---|---|---|

| High-Temp Zone | 900 °C | Sublimation | Converts solid ZnSe to vapor phase |

| Low-Temp Zone | 600 °C | Precipitation | Enables supersaturation and catalyst-driven growth |

| The Gradient | $\Delta$ 300 °C | Material Transport | Creates the pressure differential to drive gas flow |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision temperature control is the difference between a successful VLS growth and a failed experiment. KINTEK’s high-performance CVD and dual-zone tube furnace systems are engineered to provide the rigorous thermal stability and steep gradients required for 1D ZnSe nanowire production.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your lab's unique research needs.

Ready to optimize your thermal evaporation process?

Contact our technical specialists today to find the perfect high-temperature solution for your research.

Visual Guide

References

- Mingjin Liu, Yu‐Lun Chueh. Rational design of comb-like 1D–1D ZnO–ZnSe heterostructures toward their excellent performance in flexible photodetectors. DOI: 10.1039/d3nr06617g

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- In what scenarios are laboratory high-temperature tube furnaces or muffle furnaces utilized? Study MgTiO3-CaTiO3 Ceramics

- What are the technical advantages of using a PID programmable controller in tube furnace control modules?

- What are the key features of an alumina tube furnace? Achieve Precise High-Temp Processing

- What are the main applications of a vertical tube furnace? Leverage Gravity for Superior Thermal Processing

- What are the main uses of tube furnaces in laboratories? Unlock Precision in Material Synthesis and Heat Treatment

- What is the role of the tubular furnace annealing process in the synthesis of Si@SnO2? Achieve Precise Nanocoatings

- How are drop tube furnaces used in industrial settings? Boost Efficiency in Material Processing

- Why is vacuum-sealed quartz tube encapsulation necessary? Ensure High-Purity Liquid Metal Spectral Analysis